Software Library¶

Introduction¶

The CapTIvate™ Software Library is a collection of target software components designed to help shorten the development process when working with CapTIvate™ MCUs. The library is provided and supported by Texas Instruments and is delivered with the CapTIvate™ Design Center.

The library provides the following features:

Hardware abstraction of the CapTIvate peripheral features

Processing of button, slider, wheel, and proximity sensors with simple callback reporting when measurement and processing are complete

User interface management to enable a simple top level API that is easy to use

Electromagnetic compatibility features for improving noise immunity

Communications infrastructure for connecting a CapTIvate™ MCU to the CapTIvate™ Design Center during tuning or to a host processor in an application

These features provide the following main benefits:

Simplification of sensor configuration, measurement, processing and data communication

Faster application development cycles

Seamless integration with the CapTIvate™ Design Center development GUI

Reduced code footprint on devices with CapTIvate™ software in ROM

The library was designed and organized for capacitive user interface applications. However, it may also be used for other applications that require the ability to measure relative changes in capacitance.

Using This Chapter¶

This chapter consists of the following main sections:

The Overview section introduces the programming model, organization, and architecture of the library.

The Getting Started section introduces how to get up and running with the starter project, as well as how to add CapTIvate™ to an existing software project.

The How-To section provides basic code snippets that demonstrate how to do basic things.

The Technical Details section discusses advanced software implementation details.

The Base Module, Advanced Module, and Communications Module sections each provide a detailed description of the respective software module for advanced users.

The Getting Started and How-To are the most helpful sections for new users that want to quickly begin developing applications.

Device and Tools Support¶

The CapTIvate™ Software Library can only be used with MSP devices that have CapTIvate™ technology.

For a list of supported devices, visit the device tables in the device family chapter. This table also lists the minimum CCS, IAR, and CapTIvate Design Center versions for each device.

Programming Language

The software library is available in C. It follows C99 conventions and uses C99 primitives (uintX).

Delivery Mechanism¶

The CapTIvate™ Software Library and CapTIvate™ Design Center GUI have linked functionality. Features that exist in the software library are configurable via the Design Center, and data measured via the software library can be communicated back to the Design Center. Because of this, the software library and Design Center are always released together as one software download and installation. The Design Center is the sole point of access to the software library.

Change Control¶

Although they are delivered together, the CapTIvate Software Library has its own version tracking and change control. Every major library release comes with change control data in the Software Library API guide that describes any new features that have been added and any changes to existing functionality.

Overview¶

This section introduces the CapTIvate™ Software Library programming model, its organization and its architecture. It also discusses delivery of the library and version control.

Programming Model¶

The CapTIvate™ Software Library consists of several software modules and sub-modules that work together to provide various features and abstract complexity. The software library model will be introduced here in a “top-down” approach, starting from the highest point of abstraction and working downward to the lowest point.

Objects¶

The software library function calls operate on C structures which will be referred to in this section as objects. All of the main objects (C type definitions) for the software library are defined in the BASE module inside of the CAPT_Type.h header file. See the type definitions section for more details.

Generic Capacitive Touch Application

Capacitive sensing applications involve the continual measurement and post-processing of one or more capacitive sensors. As such, an application typically has the following flow:

Initialize MCU

Initialize user interface

Calibrate user interface

Loop(Forever)

If (Time to update = true)

Then

Update user interface

Report user interface status

End If

Top Level Object (User Interface Application)¶

The CapTIvate™ Software Library utilizes this basic application model as the framework for the top level API and top level object. The top level object in the software library is the user interface application, or tCaptivateApplication. Functions are provided for initializing a user interface, calibrating a user interface, and updating a user interface. These functions are implemented as CAPT_initUI(), CAPT_calibrateUI(), and CAPT_updateUI(), respectively. An application can be created just by using these three functions. This is discussed in the Use the Top Level API section.

In order to realize the top level API, the top level object (tCaptivateApplication) holds information about the state of the user interface, how many sensors there are to update, where to find those sensors, and how often to update them.

Sensor Object¶

It then follows that the next object that is needed is a sensor object, or tSensor. A sensor object is an abstracted user interface control. The software library supports button group, slider, wheel, and proximity sensor types. Every sensor object contains the following information:

Information about which electrodes to measure and how to measure them in parallel (element objects and time cycle objects)

Information about how to configure the CapTIvate™ technology peripheral for measurement (conversion control parameters)

Information about how to interpret the data from the measurement (tuning parameters)

Various functions can operate on sensor objects directly. For example, it is possible to only update a particular sensor via a call to CAPT_updateSensor() or CAPT_updateSensorWithEMC(). The top level API function CAPT_updateUI() merely calls CAPT_updateSensor() or CAPT_updateSensorWithEMC() for each sensor in the UI application.

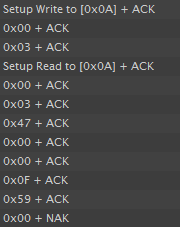

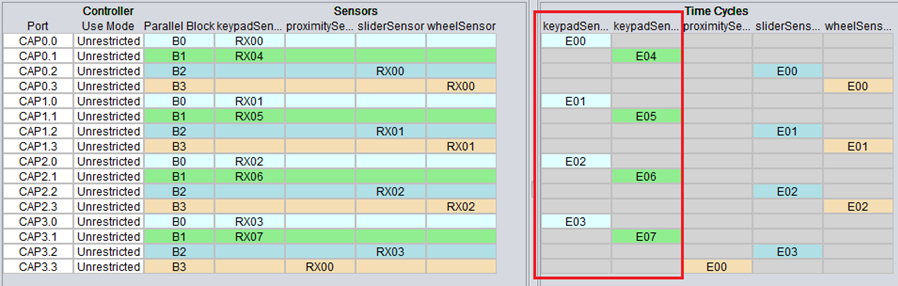

Time Cycle Object¶

The sensor object links to time cycle objects. A time cycle object is defined as tCycle. A time cycle is nothing more than a group of element objects that may be measured in parallel.

Element Object¶

Element objects are the lowest abstraction level, and can be thought of as the software representation of a single electrode, whether it is self or mutual capacitance. Each element contains the following types of information:

Information about the pin(s) the electrode is connected to

Any tuning parameters that are specific to the element (such as a touch threshold)

Any data associated with the element (such as its current sample or long term average)

Any status flags that are specific to the element (such as touch or proximity status).

Object Tree¶

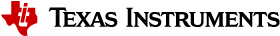

As an example, a basic application with one sensor and 4 elements organized into two time cycles could be represented with the object tree diagram shown below.

Fig. 212 Example Application Object Tree¶

In software, this configuration would have the following structure:

Element Definitions

// Sensor: keypad, Element: E00

uint16_t keypad_E00_RawCnts[CAPT_SELF_FREQ_CNT];

tCaptivateElementTuning keypad_E00_Tuning[CAPT_SELF_FREQ_CNT];

tElement keypad_E00 =

{

.ui8RxPin = 0,

.ui8RxBlock = 0,

.ui8TouchThreshold = 10,

.pRawCount = keypad_E00_RawCnts,

.pTuning = keypad_E00_Tuning,

};

// Sensor: keypad, Element: E01

uint16_t keypad_E01_RawCnts[CAPT_SELF_FREQ_CNT];

tCaptivateElementTuning keypad_E01_Tuning[CAPT_SELF_FREQ_CNT];

tElement keypad_E01 =

{

.ui8RxPin = 0,

.ui8RxBlock = 1,

.ui8TouchThreshold = 10,

.pRawCount = keypad_E01_RawCnts,

.pTuning = keypad_E01_Tuning,

};

// Sensor: keypad, Element: E02

uint16_t keypad_E02_RawCnts[CAPT_SELF_FREQ_CNT];

tCaptivateElementTuning keypad_E02_Tuning[CAPT_SELF_FREQ_CNT];

tElement keypad_E02 =

{

.ui8RxPin = 1,

.ui8RxBlock = 0,

.ui8TouchThreshold = 10,

.pRawCount = keypad_E02_RawCnts,

.pTuning = keypad_E02_Tuning,

};

// Sensor: keypad, Element: E03

uint16_t keypad_E03_RawCnts[CAPT_SELF_FREQ_CNT];

tCaptivateElementTuning keypad_E03_Tuning[CAPT_SELF_FREQ_CNT];

tElement keypad_E03 =

{

.ui8RxPin = 1,

.ui8RxBlock = 1,

.ui8TouchThreshold = 10,

.pRawCount = keypad_E03_RawCnts,

.pTuning = keypad_E03_Tuning,

};

Note that each element has three components:

An array for storing raw data after a measurement is complete (keypad_E0x_RawCnts[])

An array for storing element tuning values (keypad_E0x_Tuning[])

The element data object itself (keypad_E0x)

The first component is the raw data array. Whenever an element is updated, the raw conversion results are populated in this array. Normally, the raw data array is an array of one value (keypad_E0x_RawCnts[1]). However, if noise immunity is enabled (EMC features), the raw data array may be larger to store conversion results from a multi-frequency conversion.

The second component is the element’s tuning. Each element is calibrated with specific coarse gain, fine gain, and offset subtraction values. To understand what these parameters effect, check out the CapTIvate peripheral section of the technology chapter. Just like the raw data array, the tuning is stored in an array as well. If multi-frequency scanning is used to support noise immunity, a tuning is stored for each conversion frequency.

The final component is the element data object (tElement). This object stores the pin definition for the element. An electrode on CAPx.y would be mapped in this way, where ‘x’ is the CapTIvate™ measurement block the electrode is connected to, and ‘y’ is the pin on that block.

.ui8RxPin = y,

.ui8RxBlock = x,

In addition to the pin connection information, the element object also stores the touch threshold for this element. This specifies the level of interaction required to trigger a touch detection. Each element has its own touch threshold.

Finally, the element object is linked to the raw data and tuning arrays via pointers.

Time Cycle Definitions

// Time Cycle: keypad_C00

tElement* keypad_C00_Elements[2] =

{

&keypad_E00,

&keypad_E01,

};

tCycle keypad_C00 =

{

.ui8NrOfElements = 2,

.pElements = keypad_C00_Elements,

};

// Time Cycle: keypad_C01

tElement* keypad_C01_Elements[2] =

{

&keypad_E02,

&keypad_E03,

};

tCycle keypad_C01 =

{

.ui8NrOfElements = 2,

.pElements = keypad_C01_Elements,

};

As discussed previously, time cycles are simply a collection of element objects that have the capability of being measured in parallel. Each time cycle is composed of two components:

An array of pointers to the elements in the cycle (keypad_C0x_Elements[])

The cycle object itself (keypad_C0x)

The array of element pointers provides the link to the element objects that belong to the cycle. The cycle object links to that array, and also defines how many elements are in the cycle.

Sensor Definition

//Sensor: keypad

const tCycle* keypad_Cycles[2] =

{

&keypad_C00,

&keypad_C01,

};

tButtonSensorParams keypad_Params;

tSensor keypad =

{

// Basic Properties

.TypeOfSensor = eButtonGroup,

.SensingMethod = eSelf,

.DirectionOfInterest = eDOIDown,

.pvCallback = NULL,

.ui8NrOfCycles = 2,

.pCycle = keypad_Cycles,

.pSensorParams = (tGenericSensorParams*)&keypad_Params,

// Conversion Control Parameters

.ui16ConversionCount = 500,

.ui16ConversionGain = 200,

.ui8FreqDiv = 2,

.ui8ChargeLength = 0,

.ui8TransferLength = 0,

.bModEnable = false,

.ui8BiasControl = 3,

.bCsDischarge = true,

.bLpmControl = false,

.ui8InputSyncControl = 0,

.bTimerSyncControl = false,

.bIdleState = true,

// Tuning Parameters

.ui16ProxThreshold = 10,

.ui16NegativeTouchThreshold = 20,

.ui16ErrorThreshold = 8191,

.ui16TimeoutThreshold = 1000,

.ProxDbThreshold.DbIn = 1,

.ProxDbThreshold.DbOut = 0,

.TouchDbThreshold.DbIn = 1,

.TouchDbThreshold.DbOut = 0,

.bCountFilterEnable = true,

.ui8CntBeta = 1,

.bSensorHalt = false,

.bPTSensorHalt = true,

.bPTElementHalt = true,

.ui8LTABeta = 7,

.bReCalibrateEnable = true,

};

The sensor definition has three components:

An array of pointers to the cycles in the sensor (keypad_Cycles[])

The sensor type specific parameters (in this case, a button group) (keypad_Params)

The generic sensor object itself (keypad)

The pointer to cycle array allows the sensor to find its child objects (cycles, and through the cycles, the elements). The sensor type specific parameters component stores parameters that are specific to a sensor type. For example, a button group, slider/wheel, and proximity sensor all have different parameter structures.

The remainder of the parameters in the sensor object provides the conversion control and tuning configuration, as set up in the CapTIvate™ Design Center.

UI Application Definition

// Application

tSensor* g_pCaptivateSensorArray[CAPT_SENSOR_COUNT] =

{

&keypad,

};

tCaptivateApplication g_uiApp =

{

.state = eUIActive,

.pSensorList = &g_pCaptivateSensorArray[0],

.ui8NrOfSensors = CAPT_SENSOR_COUNT,

.ui8AppLPM = LPM0_bits,

.bElementDataTxEnable = true,

.bSensorDataTxEnable = true,

.ui16ActiveModeScanPeriod = 33,

.ui16WakeOnProxModeScanPeriod = 100,

.ui16InactivityTimeout = 32,

.ui8WakeupInterval = 5,

};

The application definition has two components:

An array of pointers to the sensors in the application (g_pCaptivateSensorArray[])

The application object itself (g_uiApp)

The array of pointers to sensors allows the top level API to find all of the sensors in the application through the application structure. Note that the application structure also defines the following items:

The low power mode to use during conversions (.ui8AppLPM)

Element and sensor data transmission enable/disable (.bElementDataTxEnable, .bSensorDataTxEnable)

The scan periods to use in active mode (.ui16ActiveModeScanPeriod)

A place holder for wake-on-proximity parameters (.ui16WakeOnProxModeScanPeriod, .ui16InactivityTimeout, .ui8WakeupInterval)

Accessing Measurement Results and Data¶

In general, the software library operates on the principle of refreshing data inside of objects, rather than returning results directly via a function call. For example, when a top level API call is made to a function like CAPT_updateUI(), all sensors in the UI and each of those sensor’s child elements will have their data structures refreshed. CAPT_updateUI() does not provide any status information directly when returning to the application.

As such, it is the responsibility of the application to directly access the results of a measurement in the appropriate object data structure. A callback function may be registered with any sensor, that will be called whenever a sensor’s data is refreshed.

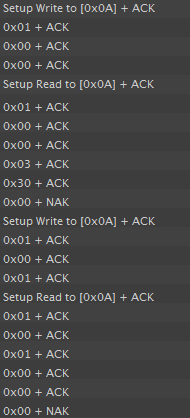

Organization and Architecture¶

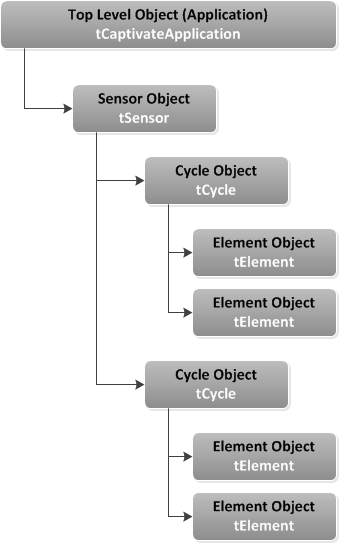

The CapTIvate™ Software Library is organized into three major modules by functionality: BASE, ADVANCED, and COMM. Each module has several sub-modules, or “layers”. Some of those sub-modules are delivered as source code; others are delivered as object code.

BASE Module¶

The BASE module is the core of the software library. It contains the hardware abstraction layer, the touch layer, the interrupt service routine (ISR), and the type definitions for the library. The touch layer acts as a “hub,” providing functions for calibrating, measuring, and processing sensors. For a detailed overview of the BASE module, see the Base Module section.

ADVANCED Module¶

The ADVANCED module provides several processing plug-ins to the BASE module. This includes button processing, slider and wheel processing, and EMC processing for noise immunity. It also contains the manager layer, which serves as the top level API for the library.

The basic software stack is shown below.

Fig. 213 CapTIvate™ Software Library Organization (Without COMMs)¶

As shown here, from the application space it is only necessary to call the top level API functions in the manager layer to have a functioning application. The touch layer handles pulling in the necessary plug-ins (button, slider/wheel, EMC), so there is no need to call these functions from the application space. For a detailed overview of the ADVANCED module, see the Advanced Module section.

User Configuration¶

Every CapTIvate™ application has a user configuration that defines all of the objects on the application. This includes the application, sensor, cycle, and element object definitions. This configuration is typically auto-generated by the CapTIvate™ Design Center.

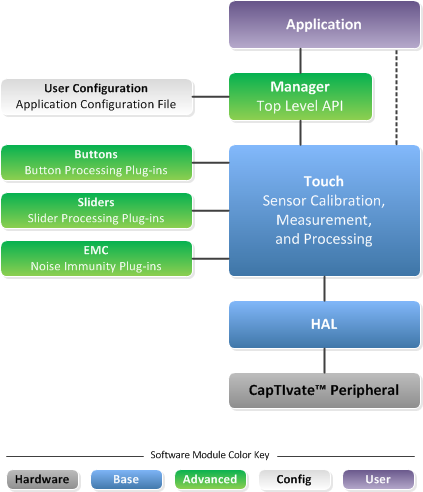

COMM Module¶

The COMM module provides communication services to either a host processor or the CapTIvate Design Center. It contains a top level interface layer, a protocol layer, serial drivers, and several data structures. The expanded software stack with the communications module is shown below. For a detailed overview of the COMM module, see the Communications Module section.

Fig. 214 CapTIvate™ Software Library Organization (With COMMs)¶

Source Code Directory Structure¶

The library source code is organized into sub-directories by module (BASE, ADVANCED, or COMM). In addition to the HAL, Touch, and ISR components, the BASE directory contains the following files:

captivate.lib This is the CCS library archive. It contains all of the functions that are pre-compiled and delivered as object code for linking against the CCS compiler.

captivate.r43 This is the IAR library archive. It contains all of the functions that are pre-compiled and delivered as object code for linking against the IAR compiler.

lnk_captivate.cmd This linker command file tells the CCS linker about the CapTIvate peripheral address space.

rom_captivate.h This is the ROM function header file. It defines the ROM function calls based on the ROM function table.

rom_map_captivate.h This is the ROM map header file. It controls which ROM functions are valid for the version of the library that is being compiled. When making ROM calls, it is best to use the MAP_* convention. See the ROM function overview for details on how to call ROM functions.

Getting Started¶

Starting from Scratch with the Starter Project¶

The recommended way to get started with a CapTIvate™ software library project is to generate a new starter software project with the CapTIvate™ Design Center. To learn how to do this, step through the new sensor project design workshop.

This section will focus on the features of the starter project itself. The software library starter projected is a ready-to-go application that includes the following software components:

The CapTIvate™ Software Library

The MSP Peripheral Driver Library (DriverLib), delivered as pre-compiled object code

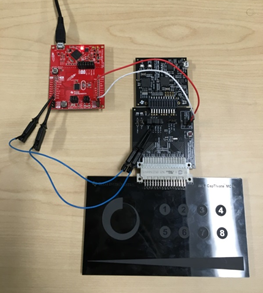

A board support package, configured for the MSP-CAPT-FR2633 EVM

An example application with wake-on-proximity support

-in

An example main.c

The starter project contains everything that is needed to bring up the MCU, calibrate and run a capacitive sensing application per the specified user configuration, and communicate measurement data. It serves as a known-good starting point for new development and tuning. Once an application is tuned, features can be added and removed from the starter application to build toward a final production application.

Directory Structure¶

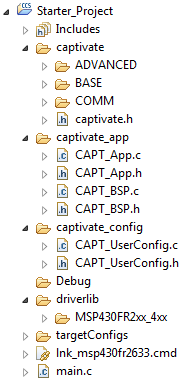

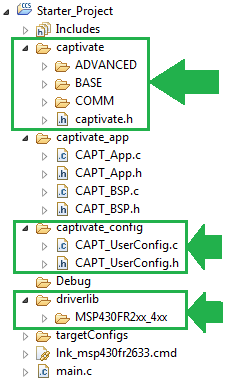

The directory structure of the starter project is shown below in CCS:

Fig. 215 Starter Project Files¶

The captivate directory contains the CapTIvate™ Software Library. This directory will likely not need to be edited during development.

The captivate_app directory contains the board support package (CAPT_BSP) and the example wake-on-proximity application (CAPT_APP). This directory contains starter files that should be modified to suit the needs of each individual application.

The captivate_config directory contains the automatically generated user configuration files that describe the capacitive sensing application as specified in the CapTIvate™ Design Center. The CAPT_UserConfig.c and CAPT_UserConfig.h files in this directory should never be edited manually, as changes made to these files are overwritten if the Design Center is utilized to update the configuration. For this reason, it is best to modify all configuration parameters from inside the Design Center.

The driverlib directory contains the MSP430 peripheral driver library. To lower compilation times, it is delivered as a pre-compiled library archive. It is possible to replace this DriverLib directory with the standard, open-source driver library, if desired.

Main¶

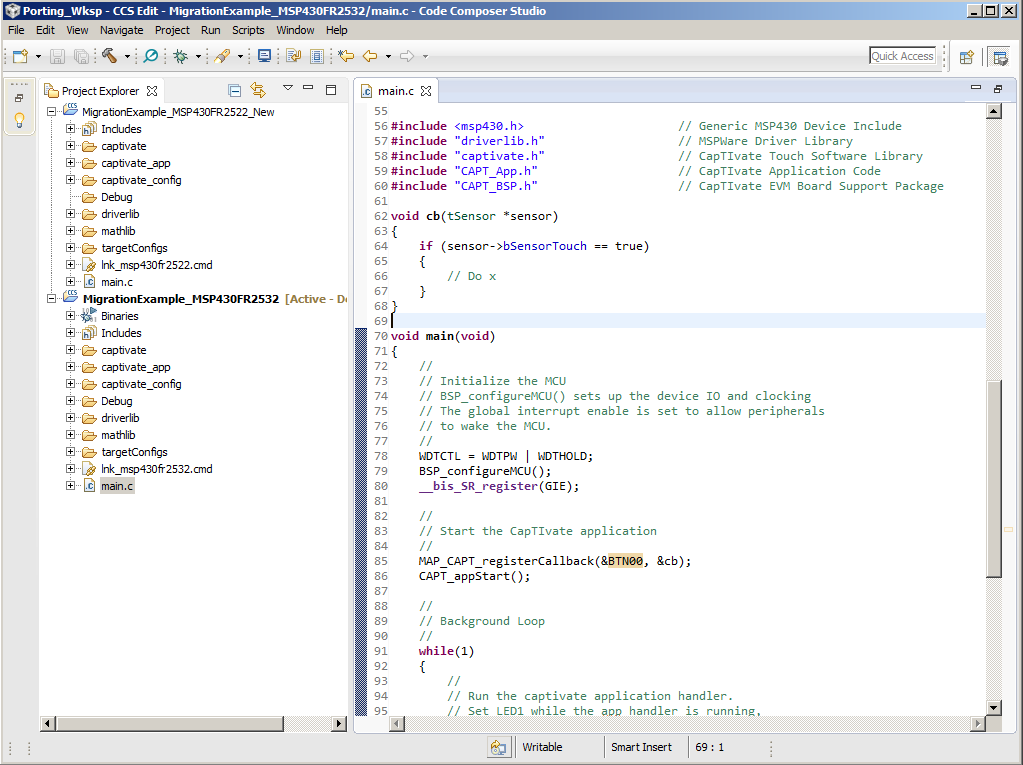

The starter application main.c is shown below:

##include <msp430.h> // Generic MSP430 Device Include

##include "driverlib.h" // MSPWare Driver Library

##include "captivate.h" // CapTIvate Touch Software Library

##include "CAPT_App.h" // CapTIvate Application Code

##include "CAPT_BSP.h" // CapTIvate EVM Board Support Package

void main(void)

{

//

// Initialize the MCU

// BSP_configureMCU() sets up the device IO and clocking

// The global interrupt enable is set to allow peripherals

// to wake the MCU.

//

WDT_A_hold(WDT_A_BASE);

BSP_configureMCU();

__bis_SR_register(GIE);

//

// Start the CapTIvate application

//

CAPT_appStart();

//

// Background Loop

//

while(1)

{

//

// Run the captivate application handler.

// Set LED1 while the app handler is running,

// and set LED2 if proximity is detected

// on any sensor.

//

LED1_ON;

if(CAPT_appHandler()==true)

LED2_ON;

else

LED2_OFF;

LED1_OFF;

//

// This is a great place to add in any

// background application code.

//

__no_operation();

//

// End of background loop iteration

// Go to sleep if there is nothing left to do

//

CAPT_appSleep();

} // End background loop

} // End main()

The main() routine disables the watchdog timer, initializes the MCU via the board support package, and starts the capacitive sensing application. It then spends the rest of its time inside the application background loop. LED1 is toggled whenever the application handler is called, and LED2 is set whenever the CAPT_appHandler() function returns true, indicating that any sensor has a proximity detection. After the app handler runs, a call to CAPT_appSleep() will put the MCU to sleep if there are no pending flags that need to be serviced. The CapTIvate™ conversion timer interrupt will wake the application each time the user interface needs to be refreshed.

Board Support Package (CAPT_BSP)¶

The board support package configures the MCU for operation with the following parameters:

Watchdog timer is disabled

16 MHz DCO Frequency

16 MHz MCLK, sourced from the DCO

2 MHz SMCLK, sourced from the DCO

32 kHz ACLK, sourced from an external crystal (if connected) or the internal REFO

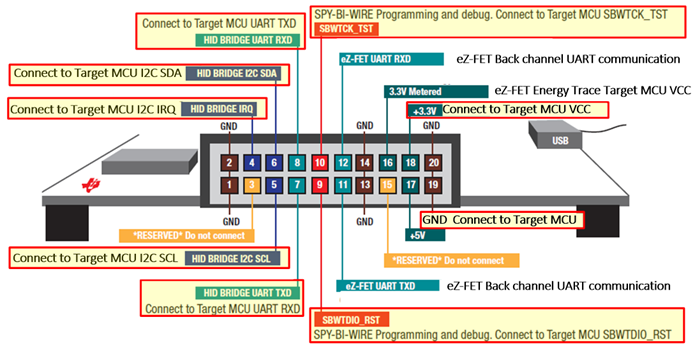

USCI_A0 and USCI_B0 are muxed to pins to allow for communication

The port muxing is configured for the CAPTIVATE-FR2633 processor module. The board support package should be ported to the platform and device used in each application!

Example Application (CAPT_App)¶

The example application demonstrates how to enable a generic capacitive sensing application with or without wake-on-proximity. It includes three functions:

CAPT_appStart()

CAPT_appHandler()

CAPT_appSleep()

CAPT_appStart()¶

This function provides an example of the functions that need to be called to configure the CapTIvate™ Software Library for operation. It handles the following tasks:

Initializing and calibrating the capacitive sensing UI via the CapTIvate™ Software Library top level API calls

Configuring and starting the CapTIvate™ timer for periodic interrupts

As discussed in the guide for using the top level API, it is necessary to call CAPT_initUI() and CAPT_calibrateUI() when starting a CapTIvate™ software library application. These functions configure the CapTIvate™ peripheral and calibrate all of the elements in the UI. If noise immunity (EMC) functionality is going to be used, it is also necessary to load an EMC configuration structure via a call to CAPT_loadEMCConfig(). Note that in the actual example CAPT_appStart() function, the CAPT_loadEMCConfig() function is a compile-time include.

CAPT_initUI(&g_uiApp);

CAPT_loadEMCConfig(&g_EMCConfig); // (Only needed if EMC features are enabled!)

CAPT_calibrateUI(&g_uiApp);

The integrated CapTIvate™ conversion timer is a periodic timer that can be used to generate an interrupt or directly trigger a conversion at a specified interval. The timer is configured via HAL function calls, as shown below. Note that these HAL functions are available in ROM on devices with CapTIvate™ software in ROM- hence the MAP_ calls. For more information on ROM software, see the ROM section.

MAP_CAPT_stopTimer();

MAP_CAPT_clearTimer();

MAP_CAPT_selectTimerSource(CAPT_TIMER_SRC_ACLK);

MAP_CAPT_selectTimerSourceDivider(CAPT_TIMER_CLKDIV__1);

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16ActiveModeScanPeriod));

MAP_CAPT_startTimer();

MAP_CAPT_enableISR(CAPT_TIMER_INTERRUPT);

These setup functions configure the timer to be sourced from ACLK (32 kHz in this starter project). An input divider of 1 is selected, and the compare register is set to the active mode scan period, converted to cycles. The macro CAPT_MS_TO_CYCLES approximates the number of 32 kHz clock cycles needed to produce the desired scan rate by multiplying the saved value (in milliseconds) by 32 (via a 5x bit shift). The timer interrupt is enabled to start the application. When the timer interrupt is asserted by the timer, the CapTIvate™ peripheral interrupt handler will run. The interrupt handler is in the BASE layer of the CapTIvate™ library, and is available in source code for transparency.

##pragma vector=CAPTIVATE_VECTOR

__interrupt void CAPT_ISR(void)

{

switch(__even_in_range(CAPT_getInterruptVector(), CAPT_IV_MAX_COUNT_ERROR))

{

// End of Conversion Interrupt

case CAPT_IV_END_OF_CONVERSION:

g_bEndOfConversionFlag = true;

break;

// Detection Interrupt

case CAPT_IV_DETECTION:

g_bDetectionFlag = true;

break;

// Timer Interrupt

case CAPT_IV_TIMER:

g_bConvTimerFlag = true;

break;

// Conversion Counter Interrupt

case CAPT_IV_CONVERSION_COUNTER:

g_bConvCounterFlag = true;

break;

// Max Count Error Interrupt

case CAPT_IV_MAX_COUNT_ERROR:

g_bMaxCountErrorFlag = true;

break;

}

__bic_SR_register_on_exit(LPM3_bits);

}

The interrupt handler will set the appropriate flag, and it always exits active. Therefore, the application merely needs to monitor the g_bConvTimerFlag boolean value to known when the timer has tripped, meaning that it is time to update the user interface.

CAPT_appHandler()¶

The application handler function must be periodically called from the application background loop, as shown in main.c. At first glance, the function appears quite complex- but really, all the application handler does is manage when the UI needs to be updated (in active mode), as well as manage the transitions between active mode and wake-on-proximity mode.

The application handler makes use of several convenience variables in the CapTIvate™ top level application object:

The active mode scan period

The wake on proximity mode scan period

The inactivity time-out

The wakeup interval

It may be configured at compile time for two different modes of operation:

Active mode only (No wake-on-proximity state handling). This is the reduced memory footprint option.

Active mode with wake-on-proximity management. This option requires more memory to handle the wake-on-proximity management.

The compile time mode is determined by settings in the user configuration header file (CAPT_UserConfig.h in the CAPT_config directory):

Active Mode Only Configuration

##define CAPT_WAKEONPROX_ENABLE (false)

##define CAPT_WAKEONPROX_SENSOR (none)

Active Mode with Wake-on-Proximity Configuration

##define CAPT_WAKEONPROX_ENABLE (true)

##define CAPT_WAKEONPROX_SENSOR (selected sensor)

These options can and should be configured through the CapTIvate™ Design Center. See the Compile Time Options section for details.

Active mode is characterized by the following behavior:

The CapTIvate™ conversion timer is used in interrupt mode to wake the CPU at a specified interval

When the g_bConvTimerFlag is asserted, CAPT_updateUI() is called to refresh all sensors in the UI under CPU control.

Wake-on-proximity mode is characterized by the following behavior:

The CapTIvate™ conversion timer is used in timer-triggered conversion mode to automatically start a conversion of a single time cycle at a specified interval without any CPU intervention

When any element in the time cycle selected for wake-on-proximity has a proximity threshold crossing or negative touch threshold crossing, the detection flag (g_bDetectionFlag) is asserted and the application switches to active mode

If the conversion counter flag (g_bConvCounterFlag)is asserted, the application switches to active mode

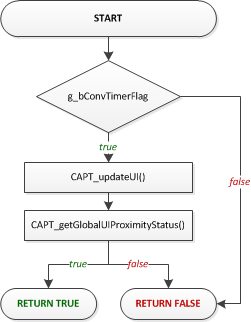

CAPT_appHandler() Compiled for Active Mode Only

The diagram below describes the behaviour of the application handler when compiled for active mode support only.

Fig. 216 CAPT_appHandler() with Active Mode Only Support¶

When compiled for active mode only, the function is pre-processed down to this basic set of functionality:

bool CAPT_appHandler(void)

{

static bool bActivity = false;

if (g_bConvTimerFlag == true)

{

//

// Clear the conversion timer flag,

// and update the UI

//

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

bActivity = CAPT_getGlobalUIProximityStatus(&g_uiApp);

}

return bActivity;

}

Since the CapTIvate™ conversion timer was already configured by CAPT_appStart(), all that is needed is to test the g_bConvTimerFlag. If it is set, then the application handler clears it, updates the UI via CAPT_updateUI(), and checks to see if any elements in the UI have a proximity detection. The function returns true if any element was in proximity, else false.

If communications are enabled, the function also checks for incoming packets as shown below:

bool CAPT_appHandler(void)

{

static bool bActivity = false;

if (g_bConvTimerFlag == true)

{

//

// Clear the conversion timer flag,

// and update the UI

//

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

bActivity = CAPT_getGlobalUIProximityStatus(&g_uiApp);

}

//

// If communications are enabled, check for any incoming packets.

//

CAPT_checkForInboundPacket();

//

// Check to see if the packet requested a re-calibration.

// If wake-on-prox is enabled and the current application state

// is wake-on-prox, disable the wake-on-prox feature during the calibration

// and re-enable it after the calibration.

//

if (CAPT_checkForRecalibrationRequest() == true)

{

CAPT_calibrateUI(&g_uiApp);

}

return bActivity;

}

A call is made to CAPT_checkForInboundPacket() to see if any packets have been received that need processing. Some parameter packets (such as a sensor’s conversion count) require that a re-calibration take place. The CAPT_checkForRecalibrationRequest() checks to see if a re-calibration request is pending.

Note that if g_bConvTimerFlag is false, the function is essentially non-blocking. This allows the background loop in main() to service other application tasks, while just periodically calling CAPT_appHandler() to see if it is time to do something.

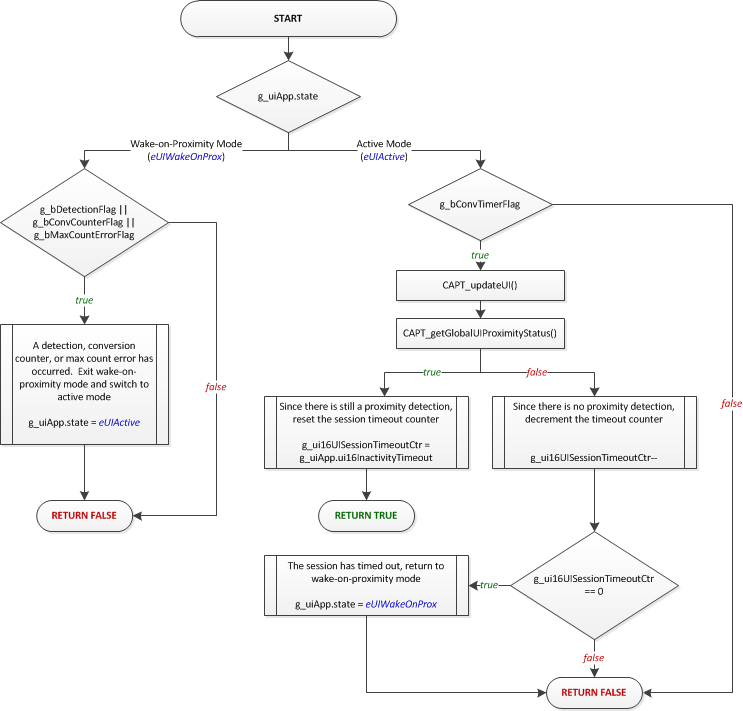

CAPT_appHandler() Compiled for Active Mode with Wake-on-Proximity Mode

When compiled with wake-on-proximity mode enabled, the application handler manages transitions between active mode and wake-on-proximity mode. The application starts in active mode, and follows the flow shown below:

Fig. 217 CAPT_appHandler() with Wake-on-Proximity Support¶

The wake-on-proximity feature allows for one time cycle to be measured and processed autonomously with no CPU interaction until a detection, counter interrupt, or error condition occurs. This is useful for applications that have a power key or a proximity sensor that is used to wake up the rest of the system, since that sensor may be scanned with no CPU overhead. When a detection does occur, the handler switches operation to active mode and the entire user interface is scanned under CPU control.

The application remains in active mode under CPU control as long as at least one element is in proximity detect. Once all elements are clear of proximity, the session time-out counter begins counting down. This counter will keep the system in active mode for the specified number of samples before returning into wake-on-proximity mode. The timeout is specified in the application object via the ui16InactivityTimeout parameter.

In addition to waking on a detection, it is also possible to periodically wake up into active mode after a certain number of conversions have taken place in wake-on-proximity mode. This is useful to ensure that all the other sensors in the system have current long term averages (LTAs) to account for environmental drift. The conversion counter interrupt may be used to specify a wakeup period.

These wakeup sources are discussed further in the wake-on-proximity description.

bool CAPT_appHandler(void)

{

static uint16_t g_ui16UISessionTimeoutCtr = 1;

static bool bActivity = false;

switch (g_uiApp.state)

{

case eUIActive:

if (g_bConvTimerFlag == true)

{

//

// Clear the conversion timer flag,

// and update the UI

//

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

bActivity = CAPT_getGlobalUIProximityStatus(&g_uiApp);

//

// If autonomous mode is enabled, check to

// see if autonomous mode should be entered.

//

if (bActivity == true)

{

//

// If there is still a prox detection,

// reset the session timeout counter.

//

g_ui16UISessionTimeoutCtr = g_uiApp.ui16InactivityTimeout;

}

else if (--g_ui16UISessionTimeoutCtr == 0)

{

//

// If the session has timed out,

// enter autonomous mode

//

g_uiApp.state = eUIWakeOnProx;

bActivity = false;

//

// Set the timer period for wake on touch interval

//

MAP_CAPT_disableISR(CAPT_TIMER_INTERRUPT);

MAP_CAPT_stopTimer();

MAP_CAPT_clearTimer();

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16WakeOnProxModeScanPeriod));

MAP_CAPT_startTimer();

g_bConvTimerFlag = false;

CAPT_startWakeOnProxMode(

&CAPT_WAKEONPROX_SENSOR,

0,

g_uiApp.ui8WakeupInterval

);

}

}

break;

case eUIWakeOnProx:

if (g_bDetectionFlag || g_bConvCounterFlag || g_bMaxCountErrorFlag)

{

//

// If a detection, conversion counter, or max count error flag was set,

// stop autonomous mode and reload an active session

//

CAPT_stopWakeOnProxMode(&CAPT_WAKEONPROX_SENSOR, 0);

g_bDetectionFlag = false;

g_bConvCounterFlag = false;

g_bMaxCountErrorFlag = false;

g_uiApp.state = eUIActive;

g_ui16UISessionTimeoutCtr = g_uiApp.ui16InactivityTimeout;

//

// Set the timer period for normal scan interval

//

MAP_CAPT_disableISR(CAPT_TIMER_INTERRUPT);

MAP_CAPT_stopTimer();

MAP_CAPT_clearTimer();

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16ActiveModeScanPeriod));

MAP_CAPT_startTimer();

CAPT_clearIFG(CAPT_TIMER_INTERRUPT);

MAP_CAPT_enableISR(CAPT_TIMER_INTERRUPT);

}

break;

}

return bActivity;

}

Note that it is possible to set a different scan period for wake-on-proximity mode than the period used in active mode. This allows for slow scanning while waiting for proximity, and faster scanning when a user is detected. Scanning less often reduces the overall power consumption.

In addition, the clock source and low power mode used during wake-on-proximity mode may be set to the VLO and LPM4, respectively, for applications that require low power but cannot use a crystal. To enable this combination, define CAPT_WOP_VLO_LPM4 at the beginning of CAPT_App.c. When this is defined, the application’s low power mode will be set to LPM4 (ACLK off), and the VLO will be selected as the input clock source to the CapTIvate timer.

For more details on designing for low power, see the low power design guide.

CAPT_appSleep()¶

The application sleep function is a safety wrapper that ensures no flags are pending when the application transitions into a low power mode. Safety is achieved by disabling interrupts, testing the flags, and then entering a low power mode while simultaneously re-enabling interrupts. This sequence protects the application from any software race conditions that might occur, such as a flag being set after the flag was tested but before the device entered low power mode.

__bic_SR_register(GIE);

if (!(g_bConvTimerFlag ||g_bDetectionFlag || g_bConvCounterFlag || g_bMaxCountErrorFlag))

{

__bis_SR_register(g_uiApp.ui8AppLPM | GIE);

}

else

{

__bis_SR_register(GIE);

}

Moving Forward¶

That’s it! The example application in captivate_app is meant to be just that- an example. Feel free to modify it to suit the needs of another application. For details on how to use the CapTIvate™ Software Library top level API, see Using the Top Level API.

Adding CapTIvate™ to an Existing Project¶

If you have an existing application using an MSP MCU and would like to add CapTIvate™ capacitive touch sensing capability to that project, this guide will discuss the important steps to take to make the integration as seamless as possible.

This guide also provides details about how to set up a new project from scratch, if the CapTIvate™ starter project is not being used.

Similar Devices¶

The CapTIvate™ MSP430FR26xx and MSP430FR25xx MCUs have a similar platform architecture as some other MSP430 FRAM devices. As such, porting an existing application from another FRAM device to an MSP430FR26xx or MSP430FR25xx MCU does not require significant effort. MCUs that are very compatible include the MSP430FR4133, MSP430FR2433, and MSP430FR2033.

Porting Approach¶

The best way to begin CapTIvate™ software library development, regardless of whether the capacitive sensing functionality will be integrated with another project or not, is to generate a starter project with the CapTIvate™ Design Center. This starter project may then be used by itself to quickly bring up a capacitive sensing application and experiment with tuning. Once that process is complete, all that is needed is to bring over the necessary CapTIvate™ software components from the starter project into the existing software project.

The previous section discusses how to generate a starter project. The new sensor project design workshop also provides a step-by-step overview of the process. Once you have a starter project, you can extract the CapTIvate™ software library components from the starter project and integrate them into the existing project.

Bringing over CapTIvate™ Software Components from a Starter Project to an Existing Project¶

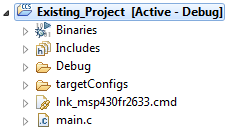

As an example, this section will discuss bringing over the CapTIvate™ software components from a starter project to an existing software project. This example will be discussed in the context of TI’s Code Composer Studio (CCS) IDE. The same principles apply to an IAR Embedded Workbench project. In this example, the existing software project will be an empty CCS project, as shown below:

Fig. 218 Empty Application¶

main.c

##include <msp430.h>

void main(void) {

WDTCTL = WDTPW | WDTHOLD;

PM5CTL0 &= ~LOCKLPM5;

while(1)

{

__no_operation();

}

}

To bring over CapTIvate™, the following steps are required:

Copy over the captivate, captivate_config, and driverlib directories and all of their content from the starter project to the existing application

Configure the existing project’s compiler settings for CapTIvate™

Configure the existing project’s linker settings for CapTIvate™

Add top level API calls to the main application to initialize, calibrate, and begin updating the newly added capacitive sensing interface

[Optional] Optimize the clock system configuration for CapTIvate™

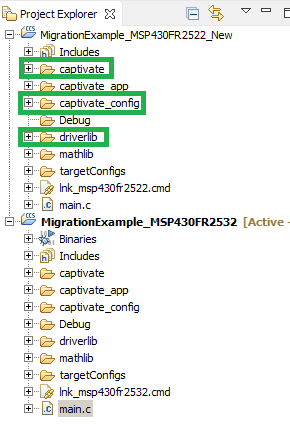

Step 1: Copying the Needed CapTIvate™ Files¶

1a. Copy the captivate, captivate_config, and driverlib directories and all of their content from the starter project to the existing application

1b. Copy the driverlib directory and all of its contents from the starter project to the existing application

Below are the directories that need to be copied from the starter project:

Fig. 219 Starter Application Files To Copy¶

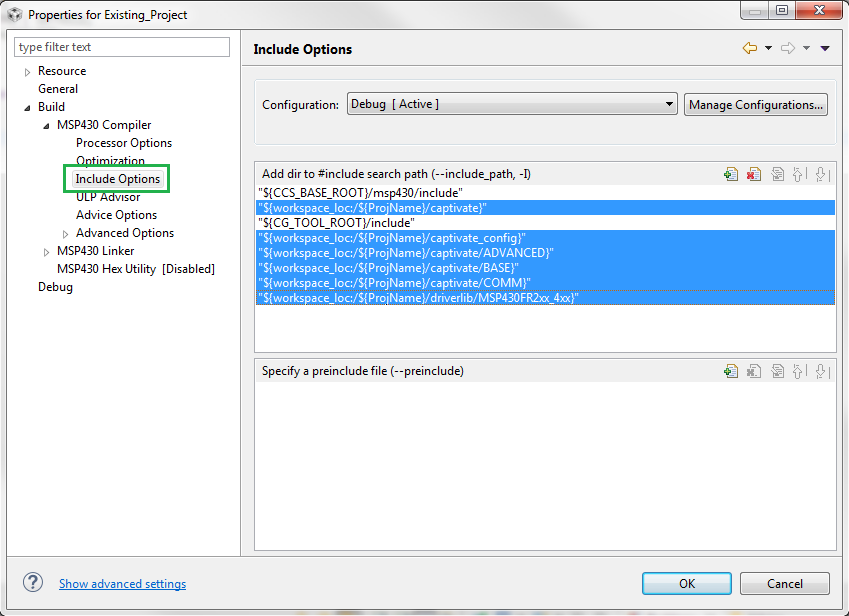

Step 2: Configuring the Existing Project’s Compiler Settings for CapTIvate™¶

2a. Add the captivate, captivate/BASE, captivate/ADVANCED, captivate/COMM, and captivate_config project directories to the existing project’s include search path, as shown below. Also add the DriverLib directory driverlib/MSP430FR2x_4xx

Fig. 220 Compiler Include Settings¶

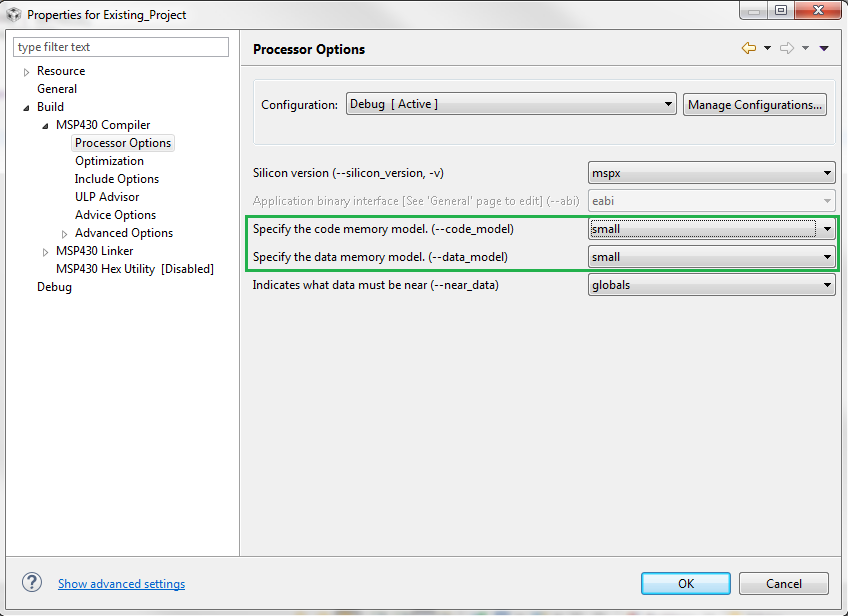

2b. Select the correct memory models for the device that is being configured by changing the existing project’s compiler processor options settings. This is required for the project to be compatible with the ROM and object code library. To determine the required memory model for a given device, refer to the memory model section.

Fig. 221 Compiler Processor Options¶

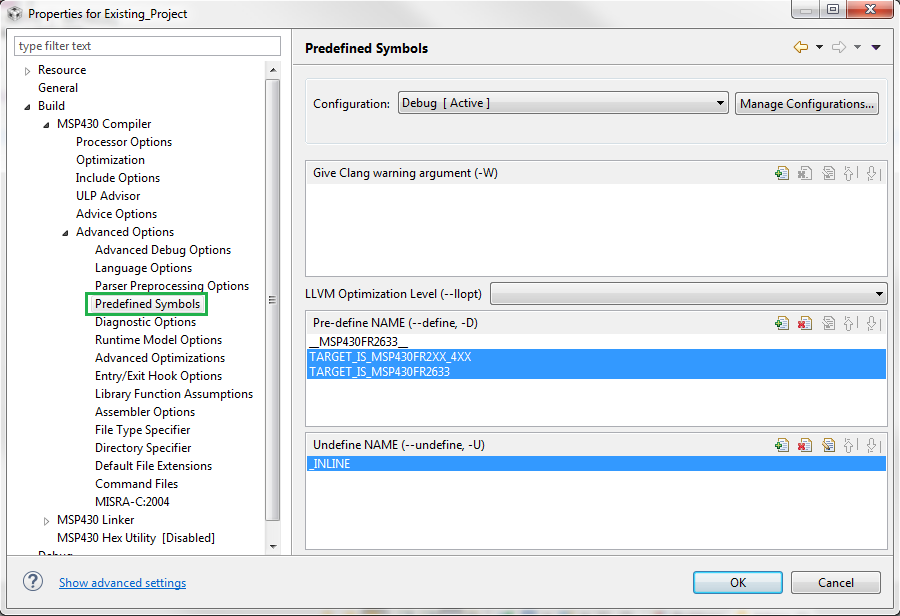

2c. Add the following definitions to the project’s compiler predefined symbol list:

TARGET_IS_MSP430FR2633 (To include the CapTIvate™ ROM functions). This definition is not needed for software library versions 1.10.xx.xx and greater, as ROM header file selection is determined at compile time based on the device definition (such as MSP430FR2633) which is set by the IDE.

TARGET_IS_MSP430FR2XX_4XX (To include the DriverLib ROM functions)

Fig. 222 Compiler Pre-Defined Symbols¶

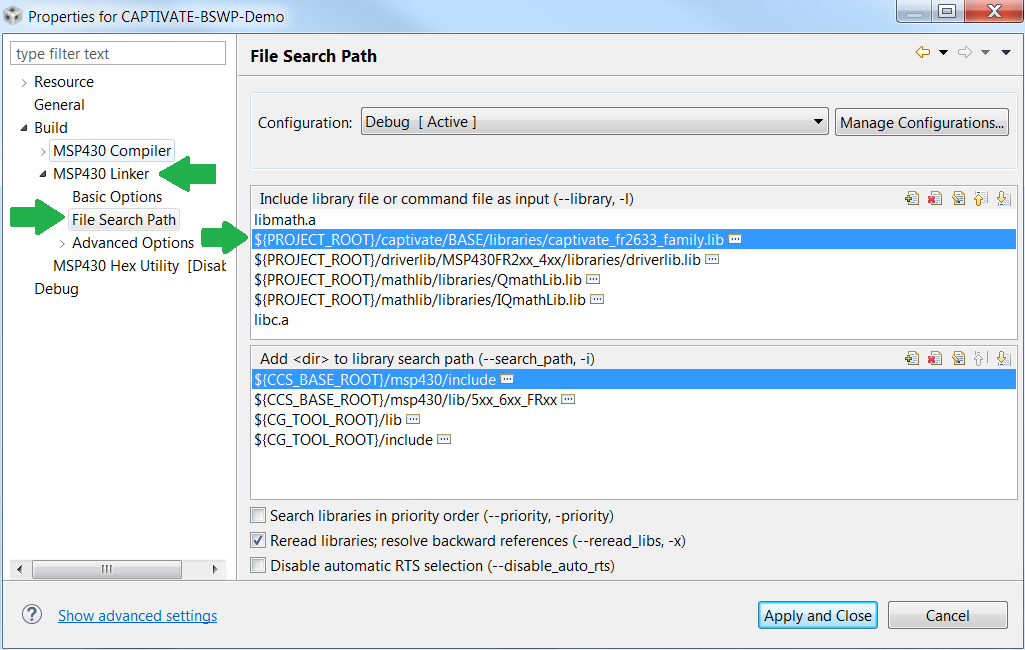

Step 3: Configuring the Existing Project’s Linker Settings for CapTIvate™¶

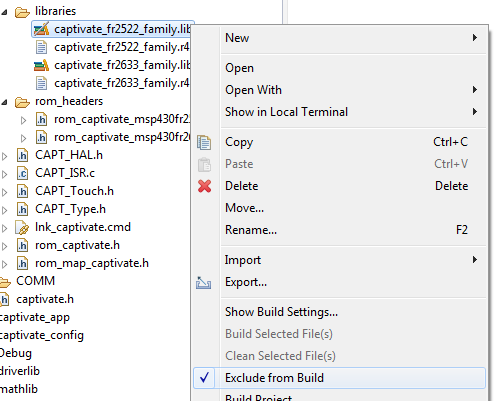

3a. Add the CapTIvate™ library archive to the linker’s input. Be sure to include the correct pre-built CapTIvate library that corresponds to the device that is being developed with. The library correspondence is described here. Once the correct library is selected, it is necessary to exclude the unused libraries from the CCS build, as shown in the example below. In the example, the project is being built for an MSP430FR2633 family device, so the MSP430FR2522 library is excluded from the build.

Fig. 223 Linker Inputs¶

If you are using the pre-compiled DriverLib directory from the starter project, add the DriverLib library archive as well, as shown below.

Fig. 224 Linker Inputs¶

Step 4: Add Top Level API Calls to Begin Using CapTIvate™¶

4a. Insert calls to initialize and calibrate the user interface once at the beginning of the application. Be sure to also add the include statement for the CapTIvate library.

// Step 4a:

CAPT_initUI(&g_uiApp);

CAPT_calibrateUI(&g_uiApp);

If noise immunity (EMC) features are going to be enabled for this design, it is also necessary to link the EMC configuration structure to the EMC module via a call to CAPT_loadEMCConfig(). This must be done before calling CAPT_calibrateUI(), so that the EMC configuration parameters are available during the calibration process.

// Step 4a with EMC:

CAPT_initUI(&g_uiApp);

CAPT_loadEMCConfig(&g_EMCConfig);

CAPT_calibrateUI(&g_uiApp);

4b. Configure the CapTIvate™ interval timer to periodically set the g_bConvTimerFlag status flag.

// Step 4b:

MAP_CAPT_selectTimerSource(CAPT_TIMER_SRC_ACLK);

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16ActiveModeScanPeriod));

MAP_CAPT_startTimer();

MAP_CAPT_enableISR(CAPT_TIMER_INTERRUPT);

4c. Begin updating the UI! Add a test in the background loop to see if the conversion timer flag has been set. If it has, clear it and update the user interface via CAPT_updateUI().

main.c

##include <msp430.h>

##include "captivate.h"

void main(void) {

WDTCTL = WDTPW | WDTHOLD;

PM5CTL0 &= ~LOCKLPM5;

// Step 4a:

CAPT_initUI(&g_uiApp);

CAPT_calibrateUI(&g_uiApp);

// Step 4b:

MAP_CAPT_selectTimerSource(CAPT_TIMER_SRC_ACLK);

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16ActiveModeScanPeriod));

MAP_CAPT_startTimer();

MAP_CAPT_enableISR(CAPT_TIMER_INTERRUPT);

while(1)

{

// Step 4c:

if (g_bConvTimerFlag == true)

{

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

}

}

}

4d. Check the touch status of the sensor by testing its bSensorTouch flag. This flag will indicate if any element in the sensor has a touch detection. After CAPT_updateUI() is called, all of the sensor and element objects in the UI will have updated status variables.

while(1)

{

// Step 4c:

if (g_bConvTimerFlag == true)

{

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

// Step 4d:

if (keypad.bSensorTouch == true)

{

__no_operation();

}

}

}

Step 5: [Optional] Optimizing the Clock System for CapTIvate™¶

The default clock frequency for the DCO is approximately 1 MHz. The CapTIvate™ Software Library runs most efficiently at 8 MHz. At 8 MHz, no memory access wait states are required, providing an efficient uA/MHz ratio. To increase the DCO clock frequency to 8 MHz, insert calls to DriverLib to configure the clock system as shown below. It is best to configure the clock system before any calls to the CapTIvate™ Software Library.

##define MCLK_FREQ 8000000

##define FLLREF_FREQ 32768

##define FLL_RATIO (MCLK_FREQ / FLLREF_FREQ)

// Step 5:

CS_initClockSignal(CS_FLLREF, CS_REFOCLK_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_ACLK, CS_REFOCLK_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_MCLK, CS_DCOCLKDIV_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_SMCLK, CS_DCOCLKDIV_SELECT, CS_CLOCK_DIVIDER_4);

CS_initFLLSettle((MCLK_FREQ/1000), FLL_RATIO);

while (CS_getFaultFlagStatus(CS_DCOFFG | CS_FLLULIFG))

{

CS_clearFaultFlag(CS_DCOFFG | CS_FLLULIFG);

}

Note that SMCLK is configured to run at DCO/4, or 2 MHz. This is the frequency that the CapTIvate™ Software Library COMM module expects in order to generate UART baud rates correctly.

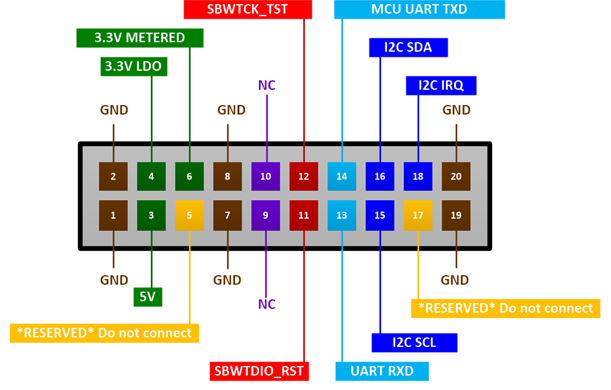

Step 6: [Optional] Muxing IO for Communications¶

To add the ability to communicate with the CapTIvate™ Design Center, it is necessary to configure the CapTIvate™ user configuration for a communication interface (UART or I2C) and mux the appropriate peripheral to device pins. See the appropriate device datasheet and device family user’s guide for information on how to mux digital functions to device pins. The starter project also provides an example of how to mux the eUSCI_A0 and eUSCI_B0 peripherals on the MSP430FR2633.

Completed Example Application¶

Below is the completed example:

main.c

##include <msp430.h>

##include "captivate.h"

##include "driverlib.h"

##define MCLK_FREQ 8000000

##define FLLREF_FREQ 32768

##define FLL_RATIO (MCLK_FREQ / FLLREF_FREQ)

void main(void) {

WDTCTL = WDTPW | WDTHOLD;

PM5CTL0 &= ~LOCKLPM5;

// Step 5:

CS_initClockSignal(CS_FLLREF, CS_REFOCLK_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_ACLK, CS_REFOCLK_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_MCLK, CS_DCOCLKDIV_SELECT, CS_CLOCK_DIVIDER_1);

CS_initClockSignal(CS_SMCLK, CS_DCOCLKDIV_SELECT, CS_CLOCK_DIVIDER_4);

CS_initFLLSettle((MCLK_FREQ/1000), FLL_RATIO);

while (CS_getFaultFlagStatus(CS_DCOFFG | CS_FLLULIFG))

{

CS_clearFaultFlag(CS_DCOFFG | CS_FLLULIFG);

}

// Step 4a:

CAPT_initUI(&g_uiApp);

CAPT_calibrateUI(&g_uiApp);

// Step 4b:

MAP_CAPT_selectTimerSource(CAPT_TIMER_SRC_ACLK);

MAP_CAPT_writeTimerCompRegister(CAPT_MS_TO_CYCLES(g_uiApp.ui16ActiveModeScanPeriod));

MAP_CAPT_startTimer();

MAP_CAPT_enableISR(CAPT_TIMER_INTERRUPT);

while(1)

{

// Step 4c:

if (g_bConvTimerFlag == true)

{

g_bConvTimerFlag = false;

CAPT_updateUI(&g_uiApp);

// Step 4d:

if (keypad.bSensorTouch == true)

{

__no_operation();

}

}

}

}

Porting an Existing CapTIvate Project to a New Device¶

If you have an existing application using a CapTIvate MCU and would like to change the CapTIvate device, this guide will discuss the important steps to take to make the integration as seamless as possible.

Porting Approach¶

The best method to seamlessly port a CapTIvate application from one device to another is to start with the CapTIvate Design Center and use it to generate a starter project for the new device. This will generate all of the needed files. Once the new project is available in CapTIvate Design Center, it is possible to generate a new starter project to import into Code Composer Studio (CCS). In this example, we will look at how to update an MSP430FR2532 4-button project to run on an MSP430FR2522 device.

Step 1: Create Starter Project for New Device¶

Step 1 in porting a development project from one CapTIvate device to another is creating a CapTIvate Design Center project based on the original design, and updating the controller to the new device.

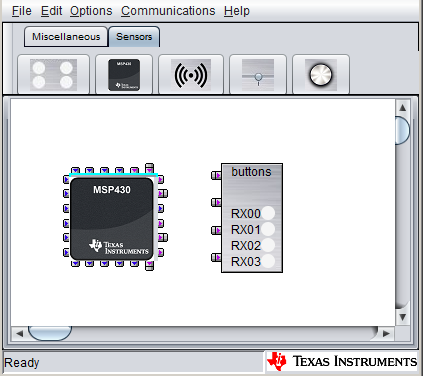

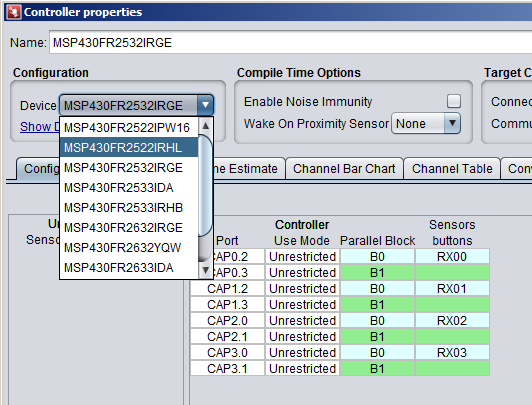

1a. Open the CapTIvate Design Center project for the original design. Let us use a 4-button application on an MSP430FR2532 as a starting point, as shown below.

Fig. 225 MSP430FR2532 Starting Project Canvas¶

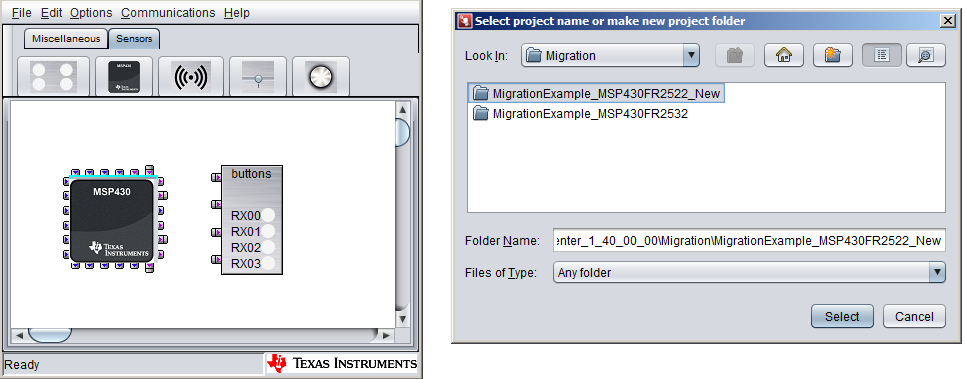

1b. Select File->Save As, and create a new project folder with a new name. In this example, we will be porting to the MSP430FR2522, so we will name the new project folder ‘MigrationExample_MSP430FR2522_New.’

Fig. 226 Save As¶

1c. Now that we have a new project for the new device (MSP430FR2522), we need to change the controller. We can keep all of the existing sensor widgets and tunings; we just need to change the controller type and re-assign sensors to IO pins on the new device.

Fig. 227 Save As¶

1d. Now that the new device is selected, the pin routing must be completed again. To achieve this, the CapTIvate Design Center auto-route feature can be used, or the pins may be assigned manually.

Step 2: Prepare a CCS Workspace¶

Set up a Code Composer Studio workspace with the original project. Then, import the starter project for the new device based on the CapTIvate Design Center project (the one that was created in Step 1 above).

Fig. 228 CCS Workspace with Original Project and New Starter Project¶

Once the starter project is imported, we can start copying the required files to the original project.

Step 3: Copying the New Files¶

To support the new device in the original project, we need the following directories from the new starter project:

/captivate (The latest CapTIvate Software Library)

/captivate_config (The new configuration files with the sensor-to-pin mapping of the new device)

/driverlib (The up-to-date driver library to support the new devices)

Fig. 229 Directories to Copy¶

Copy these directories from the new starter project, and replace all the directories in the original project with the copied directories. At this point, it is not yet possible to build the project, because the project compiler and linker settings need to be updated for the new device.

Step 4: Updating CCS Project Settings¶

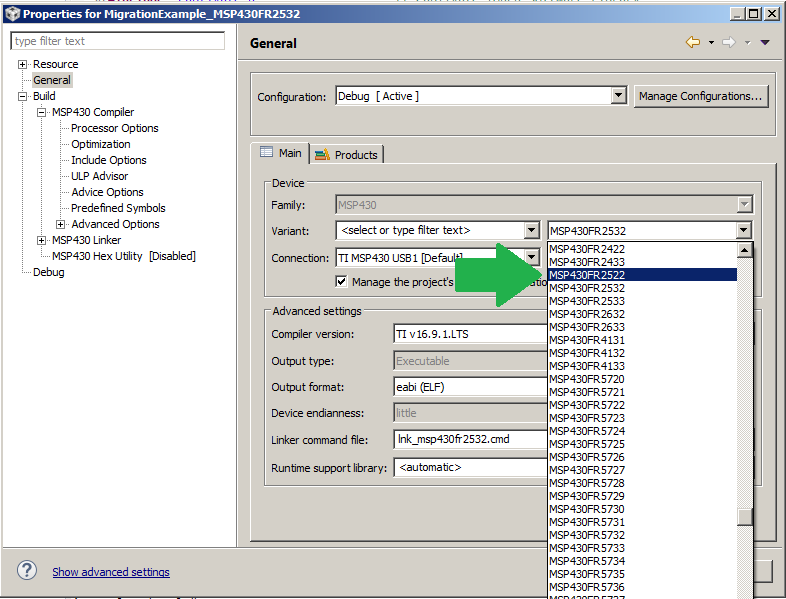

In this step, the original MSP430FR2532 CCS project settings will be updated to support the new MSP430FR2522 device.

1a. Open the CSS project properties. Change the device from MSP430FR2532 to MSP430FR2522.

Fig. 230 Project Properties¶

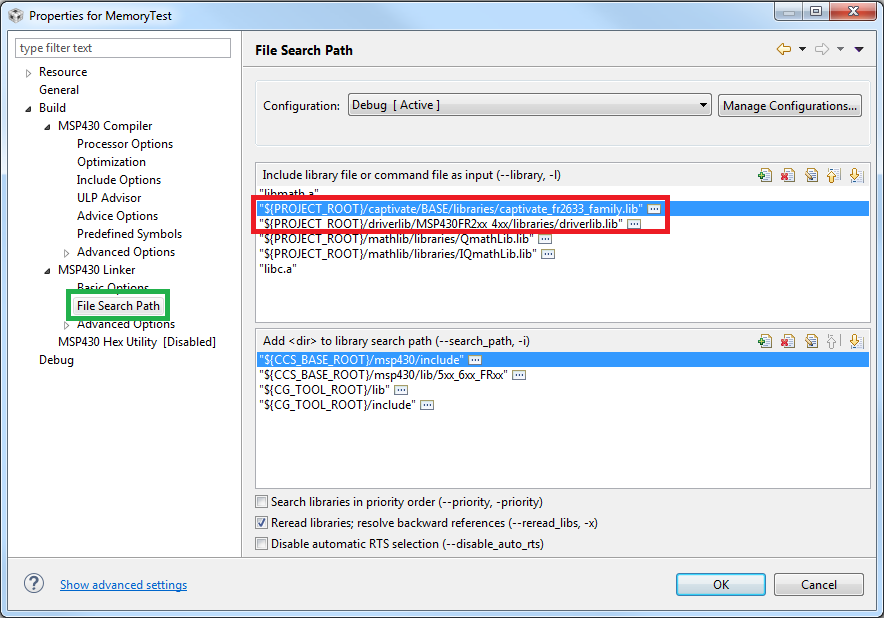

1b. In the project properties, select MSP430 Linker -> File Search Path. Change the include library file for the CapTIvate library from captivate_fr2633_family.lib to captivate_fr2522_family.lib. The library to device mapping for a given project is listed in the device family chapter. This step may not be necessary for all ports if the device that is being ported to utilizes the same library.

Fig. 231 Project Properties¶

Step 5: Update Relevant Port Muxing Settings¶

Note that this procedure did not modify the /captivate_app directory or main.c. This was intentional, to leave as much of the original project intact as possible. Be sure to adjust port muxing settings as needed to support the new device.

How-To¶

The how-to section of the CapTIvate™ Software Library chapter contains basic code snippets that demonstrate how to perform a simple task, such as measuring a sensor, checking the status of a sensor, or accessing raw data.

Use the Top Level API¶

The top level API of the CapTIvate™ Software Library provides a very simple, highly abstracted programming interface to the library. To get an application up and running, it is only necessary to have knowledge of three basic functions: CAPT_initUI(), CAPT_calibrateUI(), and CAPT_updateUI().

Scope¶

As introduced in the programming model section, the top level API functions operate solely on the top level application object, or tCaptivateApplication. This object contains all of the information that is needed to run the user interface. It contains the links to all of the sensors that are in the UI. It is important to understand that when a top level API function is used, all of the sensors that are associated with the application are affected. For example, calling CAPT_calibrateUI() causes each sensor in the UI to be calibrated.

Open Source¶

The top level API functions are delivered as open source functions in the library, so that the software designer can understand how the functions work. The functions exist in the CAPT_Manager.c and CAPT_Manager.h files, which are a part of the ADVANCED module of the library.

Setting up an Application¶

When setting up an application, it is important to note that there are two types of functions in the top level API:

Initialization functions (Run one time at start-up)

Periodic functions (called periodically while the application is running to do something)

The initialization functions are CAPT_initUI() and CAPT_calibrateUI(). CAPT_updateUI() is a periodic function. The initialization functions must be called at the beginning of the application. The behavior of each function is described below.

CAPT_initUI()¶

The CAPT_initUI() function is responsible for the following actions at start-up:

Power on the CapTIvate™ peripheral

Initialize the CapTIvate™ peripheral global settings

Configure each sensor’s IO

Initialize each sensor

If communications are enabled, initialize the library’s communication (COMM) module

Essentially, this function takes care of the one-time settings that do not change once the application is up and running. It should be called one time before any other CapTIvate™ library function is called.

CAPT_calibrateUI()¶

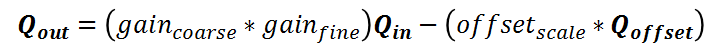

The CAPT_calibrateUI() function is responsible for obtaining coarse gain, fine gain, and offset subtraction calibration values for every element in every sensor in the application. Once these calibration values are obtained via this function call, they will be applied every time an element is measured to provide the correct amount of gain and offset. For details on how gain and offset parameters work, see the peripheral section of the technology guide.

This top-level calibration function is also responsible for determining whether to use the standard calibration routine (CAPT_calibrateSensor()) or the EMC calibration routine (CAPT_calibrateSensorWithEMC()), depending on whether or not noise immunity is enabled. If noise immunity is enabled, the EMC calibration routine provides calibration values at multiple conversion frequencies and performs additional self-test functions.

This function must be called before any UI or sensor update functions are called- otherwise, no calibration values will be present!

In addition to the first call, in certain applications it may be desirable to force a re-calibration at run-time. One example of this scenario is a mobile device that experiences a “negative” or “reverse” touch. If a user is touching a sensor during power-up or reset, the sensor will be calibrated to the touched state rather than the un-touched state. When the user lets go of the sensor, the measurement will change rapidly against the expected direction of change. This can be interpreted as a reverse touch scenario, after which it may be desirable to re-calibrate the entire user interface to ensure a good starting point.

CAPT_updateUI()¶

The CAPT_updateUI() function is responsible for the following actions:

Updating each sensor

Testing each sensor for a re-calibration condition

If communications are enabled, attempting transmission of element and/or sensor data via the COMM module

This top-level update function is also responsible for determining whether to use the standard update routine (CAPT_updateSensor())or the EMC update routine (CAPT_updateSensorWithEMC()), depending on whether or not noise immunity is enabled.

This function should be called periodically to update all of the sensors in the system. After this function is called, the following values are updated:

Raw count

Filtered count

Long term average (LTA)

Detect and negative touch flags

Touch and proximity flags

Previous touch flags

Dominant element ID (for a button group)

Position (for a slider or wheel)

Max count error flags and noise state flags

Debounce counters

After the values are updated via a call to CAPT_updateUI(), any value can be checked by referencing it in the appropriate data structure.

Simple Code Example¶

The example below demonstrates the structure of a typical application. For simplicity, this example application continuously measures the UI and does not go to sleep in between scans. To enable scheduled scanning, it is necessary to use a timer to trigger the update, such as the CapTIvate™ interval timer.

// Execute one-time setup functions

CAPT_initUI(&g_uiApp);

CAPT_calibrateUI(&g_uiApp);

while(1)

{

// Continuously update the UI

CAPT_updateUI(&g_uiApp);

}

Register a Callback Function¶

Callbacks provide a mechanism for the application to be notified when a sensor has been updated. The application must first register its “callback” function for each sensor before it can receive updates. When the callback is executed, the application can query the sensor’s data structure to determine the status of the sensor.

The library function CAPT_registerCallback() provides the registration.

Format

Sensor callback functions are passed a pointer to the calling sensor, and they must return void. An example skeleton callback function is shown below:

void my_button_callback(tSensor* pSensor)

{

// DO SOMETHING ...

}

Example

This is what it would look like to register the callback function named “my_button_callback” to the sensor BTN0000.

MAP_CAPT_registerCallback(&BTN0000, &my_button_callback);

Once an application’s callback function is registered, the callback is executed each time the corresponding sensor is scanned and processed, regardless if a proximity or touch detection has occurred. Inside the user callback, the application can perform any required sensor data and status post-processing. In a typical button application, this is where the application will check for a proximity, touch detection or slider/wheel position.

Example

Here is a typical callback example for a button that checks both when a touch is detected and a release.

void my_button_callback(tSensor* pSensor)

{

if((pSensor->bSensorTouch == true) && (pSensor->bSensorPrevTouch == false))

{

// BUTTON PRESSED

// DO SOMETHING ...

}

else if((pSensor->bSensorTouch == false) && (pSensor->bSensorPrevTouch == true))

{

// BUTTON RELEASED

// DO SOMETHING ...

}

}

Here is a callback example for a proximity sensor.

void my_proximity_callback(tSensor* pSensor)

{

if(pSensor->bSensorProx == true)

{

// PROXIMITY DETECTED

// DO SOMETHING ...

}

}

In addition to proximity and touch status, sliders and wheels also provide position status. Here is a typical callback example for a slider or wheel that checks a sensor’s position.

void my_slider_callback(tSensor* pSensor)

{

uint16_t ui16Position;

// FIRST CHECK IF THERE IS VALID TOUCH

if(pSensor->bSensorTouch == true)

{

// THEN GET THE CURRENT TOUCH POSITION ON THE SLIDER/WHEEL

ui16Position = (uint16_t)((tSliderSensorParams*)pSensor->pSensorParams)->SliderPosition.ui16Natural;

// DO SOMETHING WITH POSITION ...

}

}

Access Element State Data¶

Each element in a sensor has a set of boolean state flags that indicate its status. The following flags are provided:

Detection

Negative touch detection

Proximity

Touch

Built-in-self-test (BIST) status

Noise status

When a sensor is updated (via CAPT_updateUI(), CAPT_updateSensor(), or CAPT_updateSensorWithEMC()), these status flags are updated for every element within the sensor. There are multiple ways to retrieve the data for processing.

Accessing Element State Data Directly¶

It is possible to access element state data directly in an element’s data structure. To do this, it is necessary to know the name of the variable in the element. An example is shown below that uses element 0 of a sensor named keypad to control some other function, such as illuminating an LED.

extern tElement keypad_E00;

void updateLED(void)

{

if(keypad_E00.bTouch == true)

{

// ILLUMINATE LED

}

else

{

// TURN LED OFF

}

}

Accessing Element State Data Indirectly¶

Note that in the example above, it was necessary to forward declare keypad_E00. It is also possible to “look up” E00 of the keypad sensor though the parent sensor structure, as shown below. All sensor structures are forward declared in the user configuration header file (CAPT_UserConfig.h), and do not need to be re-declared. The element of interest is accessed via the cycle pointer array and the element pointer array of that cycle.

void updateLED(void)

{

if(keypad.pCycle[0]->pElements[0]->bTouch == true)

{

// ILLUMINATE LED

}

else

{

// TURN LED OFF

}

}

Generating a Status Bit Field for all Elements in a Sensor¶

The above access methods shown are simple and do not require very much memory. However, they only provide data for one element. The library function CAPT_getElementStateBitField() returns a bit field in which each element is represented with a bit position. The bit field supports up to 64 elements. The return type is a 64-bit unsigned integer, which may be casted down to the size that is needed for the application.

Elements are mapped to bit positions starting with the first element of the first cycle to the last element of the last cycle. For example, a sensor with two cycles and two elements in each cycle would have the following mapping:

Return value bit 0 (0x01): Cycle 0 Element 0

Return value bit 1 (0x02): Cycle 0 Element 1

Return value bit 2 (0x04): Cycle 1 Element 0

Return value bit 3 (0x08): Cycle 1 Element 1

This function may be used to query any of the element status flags. The example below tests the touch status flag. If element 0 and element 1 (BIT0 and BIT1), or 0x03, are touched, the LED would be illuminated.

void updateLED(void)

{

uint8_t multiTouchState;

multiTouchState = (uint8_t)CAPT_getElementStateBitField(&keypad, eTouchStatus);

// If '0x03', or element 0 and element 1, are both in detect:

if (multiTouchState & 0x03)

{

// ILLUMINATE LED

}

else

{

// LED OFF

}

}

Accessing a Sensor’s Global Flags¶

Many of the flags that are available at the element level are also available as global flags at the sensor level. The global, sensor-level flags operate as a logical OR of all elements in the sensor. In other words, if any element’s flag is set, the sensor’s global flag is also set. It this way, it is possible to quickly test one flag to see if anything is happening with a sensor. Then, if something is, the element flags can be used to identify which element(s) threw the flag. In the example below, the LED would be illuminated if any element in the sensor was touched.

void sensorHandler(tSensor* pSensor)

{

if(pSensor->bSensorTouch == true)

{

// ILLUMINATE LED

}

else

{

// TURN LED OFF

}

}

In addition to the global sensor touch flag (bSensorTouch), there is also a global sensor previously touched flag (bSensorPrevTouch). This flag is set if bSensorTouch was set on the previous sample. This can be used as a mechanism to determine if a touch is new (meaning someone just touched the button) versus stale (meaning the touch on this sample is a continuation of a previously started touch). This allows for toggling between states, as shown below:

void sensorHandler(tSensor* pSensor)

{

if((pSensor->bSensorTouch == true) && (pSensor->bSensorPrevTouch == false))

{

// TOGGLE A FUNCTION

}

}

Sensor Status Flag Reference Table¶

The table below lists the available sensor status flags that all sensors have, and the name of the parameter to use when accessing it.

Description |

Sensor Structure Parameter |

|---|---|

Touch |

.bSensorTouch |

Previous Touch |

.bSensorPrevTouch |

Proximity |

.bSensorProx |

Detect (Prox Detect Pre-Debounce) |

.bSensorDetect |

Negative Touch |

.bSensorNegativeTouch |

Noise State Detected |

.bSensorNoiseState |

Max Count Error |

.bMaxCountError |

Sensor Calibration Error |

.bCalibrationError |

The table below lists the trigger condition of each status flag and recommended use of the flags.

Description |

Trigger Condition |

Recommended Use |

|---|---|---|

Touch |

This flag is set if the Conversion counts of any element in this sensor crosses the Touch Threshold after debounce. |

Application can take action after the sensor detects a touch event. |

Previous Touch |

This flag is set if the previous sensor status is touch. |

This flag can be used to determine if the touch is a new touch or a continuous touch event. |

Proximity |

This flag is set if the Conversion counts of any element in this sensor crosses the Proximity Threshold after debounce. |

Application can take action after the sensor detects a proximity event. |

Detect (Prox Detect Pre-Debounce) |

This flag is set if the Conversion counts of any element in this sensor crosses the Proximity Threshold before debounce. |

Application can take action after the sensor detects a proximity event before applying debounce. |

Negative Touch |

This flag is set if the Conversion counts of any element in this sensor crosses the Negative Touch Threshold before debounce. |

CapTIvate Library will automatically perform a recalibration in CAPT_updateUI function if this flag is set. For application use case, please find more information in the Glossary descriptions of Negative Touch Threshold. |

Noise State Detected |

This flag is set if the system detects the noise level in the conversion results of any element in this sensor exceeds the noise threshold. You need to enable noise immunity feature to enable this flag. You can enable noise immunity and set noise threshold in CapTIvate Design Center controller property. |

CapTIvate Library does not do anything with this flag.This is an indication flag to let the application know there is noise in the measurement result higher than the defined threshold. Application can take action accordingly. |

Max Count Error |

This flag is set if the Conversion counts of any element in this sensor exceeds the Error Threshold. |

CapTIvate Library will automatically perform a recalibration in CAPT_updateUI function if this flag is set. For application use case, please find more information in the Glossary descriptions of Error Threshold. |

Sensor Calibration Error |

This flag is set if any element in this sensor maximum coarse and fine gain ratios have been selected and are not enough to achieve the desired conversion gain setting. Or the maximum offset setting have been selected and is not enough to achieve the desired conversion count setting. |

CapTIvate Library does not do anything with this flag. This flag indicates that either the external sensor capacitance is out of the supported range. Or the desired conversion gain and conversion count is too high or too low for the system to calibrate to. Application can use this flag during the development phase. |

Element Status Flag Reference Table¶

The table below lists the available status flags that all elements have, and the name of the parameter to use when accessing it.

Description |

Element Structure Parameter |

CAPT_getElementStateBitField() Parameter |

|---|---|---|

Touch Detection |

.bTouch |

eTouchStatus |

Proximity Detection |

.bProx |

eProxStatus |

Negative Touch Detect |

.bNegativeTouch |

eNegativeTouchStatus |

Detect |

.bDetect |

eDetectStatus |

Built-in-self-test Fail |

.bBISTFail |

eBISTStatus |

Noise State Detected |

.bNoiseDetected |

eNoiseStatus |

The detect status is the un-debounced state of the prox status. When an element is in detect but not in prox, this means that the long term average tracking filter is disabled, but the state change into proximity detection is not yet complete because it is currently being debounced.

The table below lists the trigger condition of each element status flag and recommended use of the flags.

Description |

Trigger Condition |

Recommended Use |

|---|---|---|

Touch Detection |

This flag is set if the Conversion counts of this element crosses the Touch Threshold after debounce. |

Application can take action after the element detects a touch event. |

Proximity Detection |

This flag is set if the Conversion counts of this element crosses the Proximity Threshold after debounce. |

Application can take action after the element detects a proximity event. |

Negative Touch Detect |

This flag is set if the Conversion counts of this element crosses the Negative Touch Threshold before debounce. |

CapTIvate Library will automatically perform a recalibration in CAPT_updateUI function if this flag is set. For application use case, please find more information in the Glossary descriptions of Negative Touch Threshold. |

Detect |

This flag is set if the Conversion counts of this element crosses the Proximity Threshold before debounce. |

Application can take action after the sensor detects a proximity event before applying debounce. |

Built-in-self-test Fail |

Not implemented in the current version of the CapTIvate library. |

|

Noise State Detected |

This flag is set if the system detects the noise in the conversion results of this element exceeds the noise threshold. You need to enable noise immunity feature to enable this flag. You can enable noise immunity and set noise threshold in CapTIvate Design Center controller property. |

CapTIvate Library does not do anything with this flag.This is an indication flag to let the application know there is noise in the measurement result higher than the defined threshold. Application can take action accordingly. |

Access the Dominant Button¶

Button group sensors output a dominant button ID that corresponds to the element with the highest delta response. This is useful for keypads which do not require multi-touch but would like to have some level of nearby key rejection. For example, if a user is touching in between to keys, the dominant key with the highest delta response will be reported.

When a button group sensor is updated (via CAPT_updateUI(), CAPT_updateSensor(), or CAPT_updateSensorWithEMC()), the dominant element value is updated.

Elements are mapped to IDs starting with the first element of the first cycle to the last element of the last cycle. For example, a sensor with two cycles and two elements in each cycle would have the following mapping:

0: Cycle 0 Element 0

1: Cycle 0 Element 1

2: Cycle 1 Element 0

3: Cycle 1 Element 1

Accessing the Dominant Button Directly¶

The example below shows how to directly access the value in the tButtonSensorParams structure. The LED is illuminated if a touch is present and the dominant key is the first element.

extern tButtonSensorParams keypadSensor_Params;

void updateLED(void)

{

if (keypadSensor.bSensorTouch == true)

{

if (keypadSensor_Params.ui16DominantElement == 0x00)

{

// ILLUMINATE LED

}

else

{

// TURN OFF LED

}

}

else

{

// TURN OFF LED

}

}

Accessing the Dominant Button Indirectly¶

Note that in the example above, it was necessary to forward declare keypadSensor_Params. It is also possible to “look up” these parameter structures through the parent sensor structure, as shown below. All sensor structures are forward declared in the user configuration header file (CAPT_UserConfig.h), and do not need to be re-declared. It is necessary to type-cast the parameter structure based on the type of sensor.

void updateLED(void)

{

uint8_t dominantButton;

if (keypadSensor.bSensorTouch == true)

{

dominantButton = ((tButtonSensorParams*)(keypadSensor.pSensorParams))->ui16DominantElement;

if (dominantButton == 0x00)

{

// ILLUMINATE LED

}

else

{

// TURN OFF LED

}

}

else

{

// TURN OFF LED

}

}

Accessing the Dominant Button with a Function Call¶

The final way to access the dominant button value is via a function call to CAPT_getDominantButton() or CAPT_getDominantButtonAddr(). The former function returns the ID of the dominant button, while the latter function returns the memory address (essentially a pointer to) the dominant element.

The example below demonstrates accessing the dominant button ID via a function call.

void updateLEDs(void)

{

uint8_t dominantElement;

if ((keypadSensor.bSensorTouch==true) && (keypadSensor.bSensorPrevTouch==false))

{

dominantElement = CAPT_getDominantButton(&keypadSensor);

if (dominantElement == 0)

{

LED1_OFF;

LED2_OFF;

}

else if (dominantElement == 1)

{

LED1_ON;

LED2_OFF;

}

else if (dominantElement == 2)

{

LED1_OFF;

LED2_ON;

}

else if (dominantElement == 3)

{

LED1_ON;

LED2_ON;

}

}

}

The example below demonstrates processing of the dominant button based on a pointer to the dominant element.

extern tElement keypadSensor_E00;

extern tElement keypadSensor_E01;

extern tElement keypadSensor_E02;

extern tElement keypadSensor_E03;

void updateLEDs(tSensor *sensor)

{

tElement* dominantElement;

if ((keypadSensor.bSensorTouch==true) && (keypadSensor.bSensorPrevTouch==false))

{

dominantElement = CAPT_getDominantButtonAddr(&keypadSensor);

if (dominantElement == &keypadSensor_E00)

{

LED1_OFF;

LED2_OFF;

}

else if (dominantElement == &keypadSensor_E01)

{

LED1_ON;

LED2_OFF;

}

else if (dominantElement == &keypadSensor_E02)

{

LED1_OFF;

LED2_ON;

}

else if (dominantElement == &keypadSensor_E03)

{

LED1_ON;

LED2_ON;

}

}

}

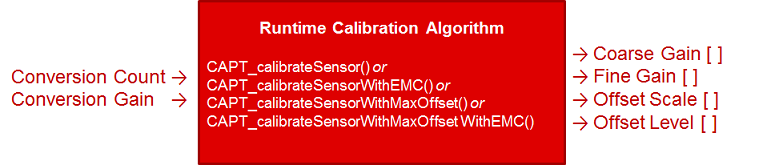

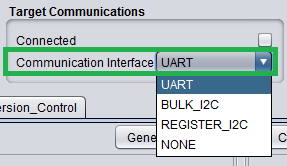

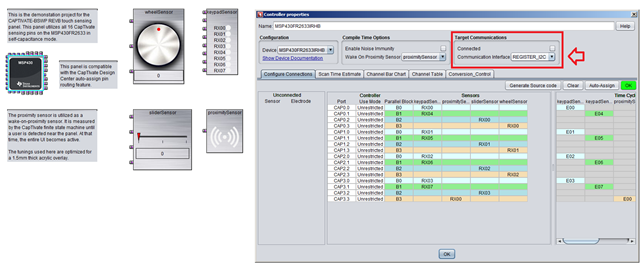

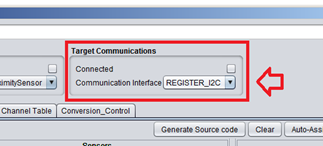

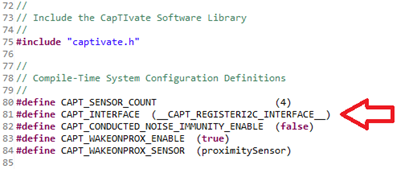

Access Slider or Wheel Position Data¶