Design Guide¶

Introduction¶

Capacitive touch detection is sometimes considered more art than science. This often results in multiple design iterations before the optimum performance is achieved. There are, however, good design practices for circuit layout and principles of materials that need to be understood to keep the number of iterations to a minimum.

Good sensor design are the foundation for a successful touch product.

The purpose of this design guide is to provide guidance for the design and layout of capacitive touch sensors so that they can achieve maximum performance. By achieving maximum performance in the hardware, the CapTIvate™ capacitive touch software library can perform the capacitive touch measurements consuming the lowest power. Tuning guides, along with the CapTIvate™ Design Center are used to help tune the performance of the capacitive touch application.

Starting a New Design¶

Starting any new capacitive touch design can be a challenging task. This section will guide you through this process and help determine what is important for your design and end application.

Identify Sensors

First we want to identify the types of sensors that you are considering for your application and provide some basic design guidelines.

Identify Care Abouts

Next it is important to identify any special requirements for the end application, such as low-power, noise immunity, moisture, etc.

Design Process¶

Creating a reliable capacitive touch design can be a time consuming process that starts with designing sensors, laying out a PCB, writing lots of code and finally performing an iterative sensor tuning process to achieve the desired performance. The CapTIvate™ Technology sensor design process accelerates the capacitive touch development cycle through automation, helping get your product to market faster.

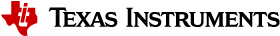

Creating a new sensor design

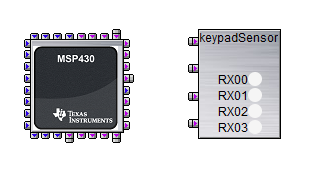

We begin the process by creating a new capacitive touch design using the CapTIvate™ Design Center. With a few simple drag-n-drop inputs and configuration selections, the CapTIvate™ Design Center will automatically determine the optimal pin assignments between the target MCU and the sensors (CapTIvate™ Technology peripheral can measure four channels in parallel). Alternatively, connections can be manually assigned or reserved for those applications with specific routing requirements.

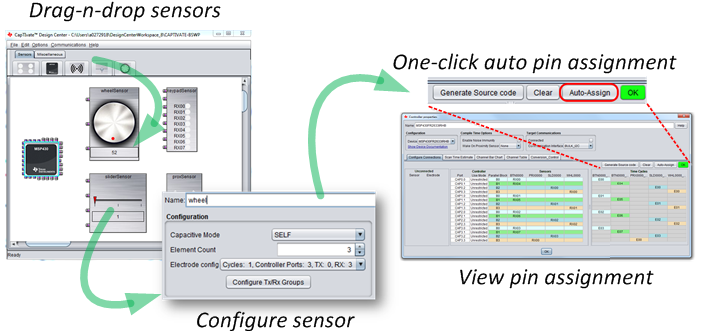

Layout PCB

Once the pin assignments have been made, the MCU pin to sensor electrode connection information is exported to a .csv file and can be used during the PCB layout and design.

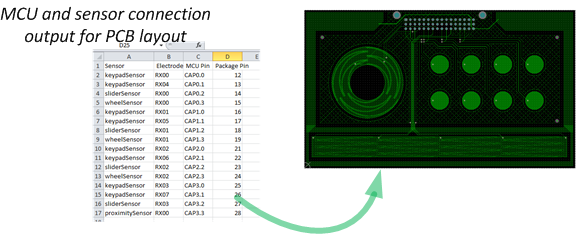

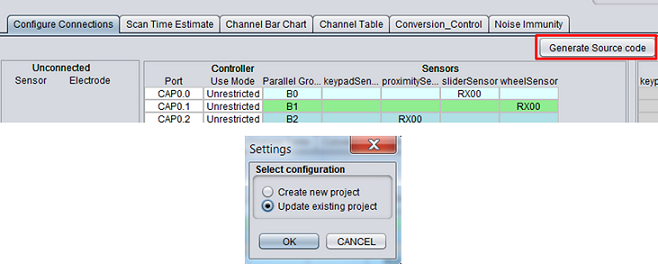

Generate configuration and starter project files

Now we are ready to create a custom starter code project based on our sensor design. The CapTIvate™ Design Center creates a fully working capacitive touch application that can be imported into Texas Instruments Code Composer Studio (CCS) or IAR Embedded Workbench. In addition to the application, the CapTIvate™ Software Library and MSP430 driver-lib are automatically included with the project, as portions of the libraries are needed during the development cycle.

Program target MCU

Import the generated CapTIvate™ project into Code Composer Studio or IAR IDE, compile and program the target MCU. The specific steps to perform the programming operation depend on the IDE, however, once the target MCU is programed, you are ready to start running your first capacitive touch application without having to write a single line of code!

Didn’t get it right the first time? Changes to a sensor design is simple. We use the CapTIvate™ Design Center to modify our sensor design project, then generate an updated configuration file. Simply copy the new configuration file and replace the existing one in the CCS or IAR application project and rebuild the application. That’s it!

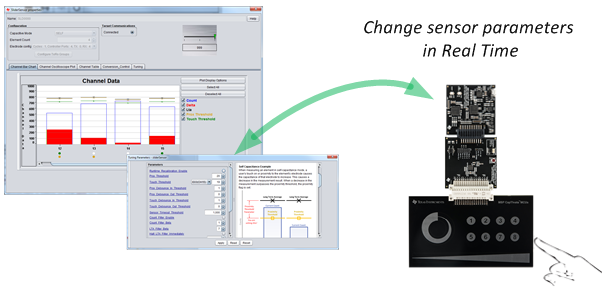

Tune Sensors

Our PCB is ready to go so we can now begin the process of tuning the sensors for the desired touch and feel. With the MCU programmed with our application and running, the sensors are scanned and real-time data is transmitted to the CapTIvate™ Design Center using the high-speed HID serial bridge MCU on the CAPTIVATE-PGMR PCB. The CapTIvate™ Design Center has several different views to display and monitor the sensor response and allow quick modifications in real-time to the sensor’s parameters, providing instant feedback.

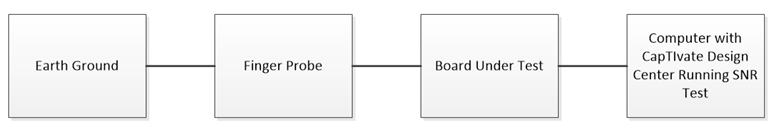

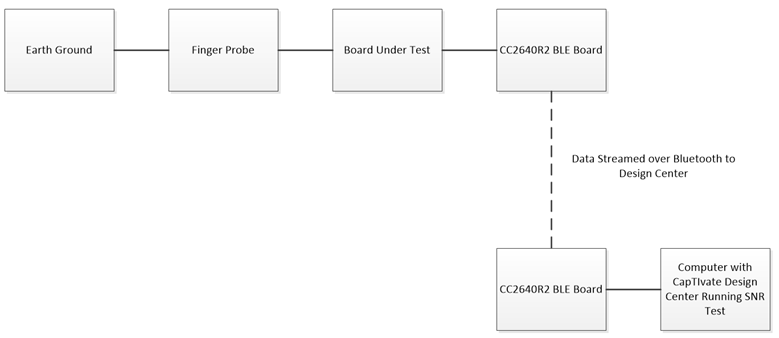

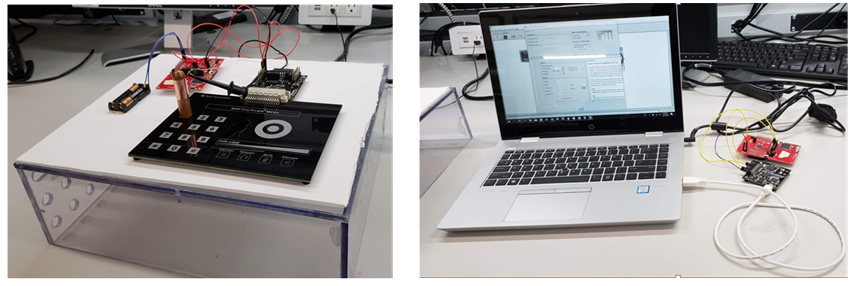

Measure SNR and Design Margins

Now that a first-pass tuning has been created, TI recommends assessing the reliability of each sensor by utilizing the SNR measurement tool in the CapTIvate Design Center to measure the SNR and design margins. For details on this process, see the application report Sensitivity, SNR, and Design Margin in Capacitive Touch Applications.

Generate final configuration

Once our desired touch and feel is achieved, the final sensor configuration can be generated and then programmed into the target MCU. That’s it! Using the steps outlined above, capacitive sensor design time can be dramatically reduced.

Congratulations! You are done with your design and ready to go to market.

Best Practices¶

In this section we will cover both mechanical as well as common layout practices.

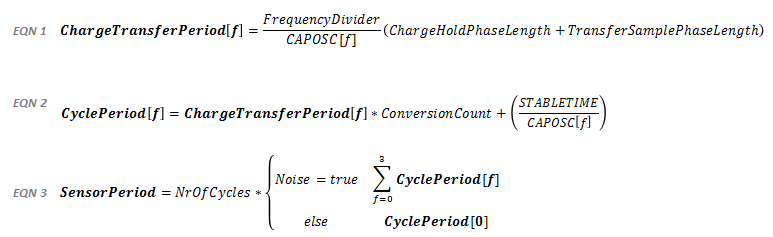

Capacitive touch detection is a type of analog-to-digital converter (ADC), specifically a capacitance-to- digital converter. As with most ADCs, the terms of interest are resolution, signal-to-noise ratio (SNR), and linearity, in the specific cases of wheels and sliders. Throughout this document, the design guidance helps to maximize signal, minimize noise, and address when these two goals are at odds.

As mentioned above, the basis of capacitive touch detection is the ability to measure a change in capacitance. This change in capacitance is the signal that the capacitive touch solution identifies. The term sensitivity is often used to describe the signal strength a more sensitive solution has a stronger signal.

Sensitivity is measured in capacitance per counts. In the context of capacitive touch detection, the magnitude of change introduced by a touch is on the order of picofarads or hundreds of femtofarads. It is not uncommon for a solution to see a touch introduce 1 pF of change and be measured as 300 counts. And while the sensitivity might be 3.3 fF/count, this should not be considered until the noise is factored in. Refer to the section on Noise below.

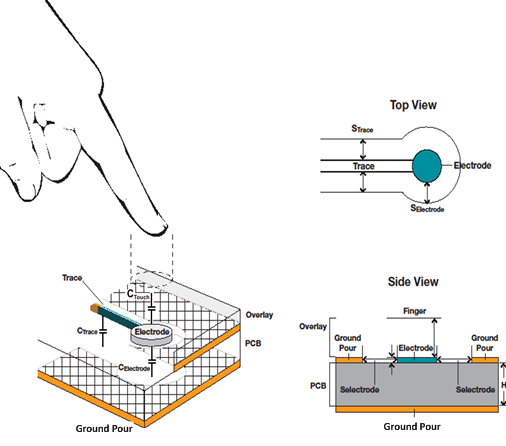

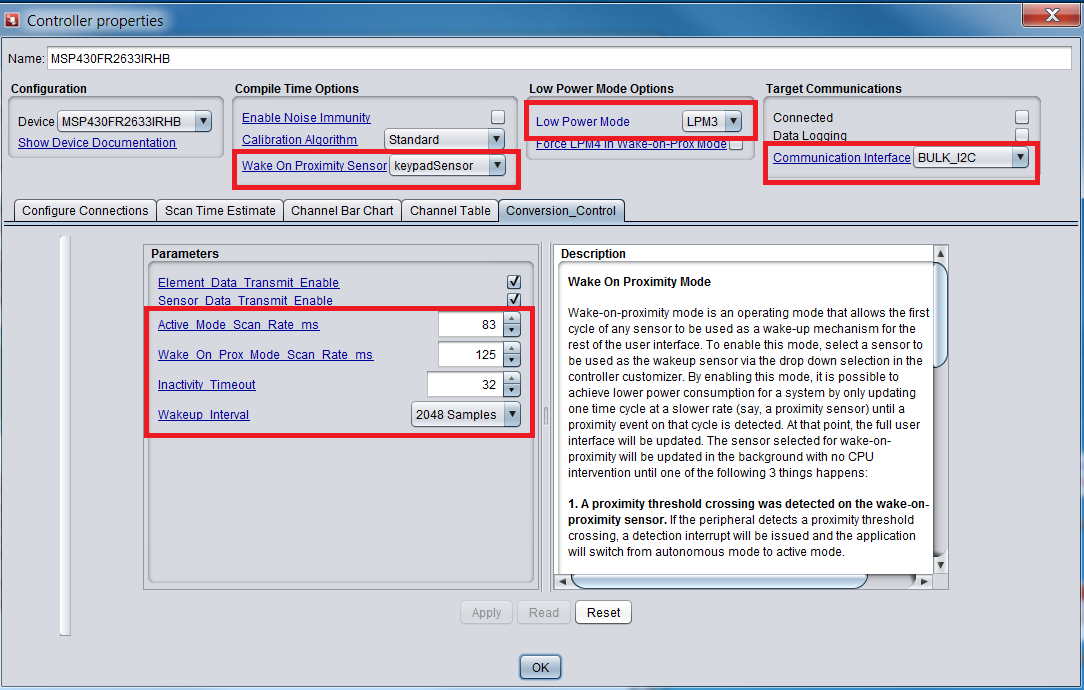

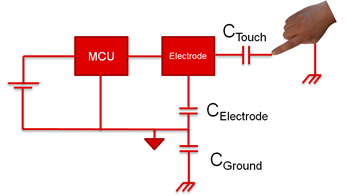

Sensitivity can be controlled within firmware, but the goal is to provide good sensitivity with the hardware, so that the lowest sensitivity settings can be used in firmware, which provides the lowest-power solution. Referring to the Equivalent circuit for a self capacitive sensor, C_touch must be maximized, while the other four capacitances must be minimized. The capacitances of the trace and electrode are approximated as parallel plate capacitances. The following equation serves as the basis for layout recommendations.

C = Er x E0 x A/d (1)

The dielectric constant (Er), area (A), and distance (d) are described throughout this document with the intent of positively influencing the capacitance for a touch system.

Although parasitic capacitance is presented separately, it is a part of the sensitivity and signal. As already mentioned, the capacitance of interest is the relative change in capacitance. The change in capacitance is based upon the touch interaction, but this change is perceived relative to the parasitic capacitance of the system. The parasitic capacitance is also called the steady-state capacitance or baseline capacitance. If the introduced change is 100 fF, then the sensitivity, which is the relative change in capacitance, can be increased by decreasing the parasitic capacitance.

The capacitances C_trace, C_electrode, and C_parasitics are generically referred to as parasitic capacitance.

Mechanicals¶

The mechanicals are the mechanical characteristics of the design. The mechanicals include the overlay material, ink on top of the overlay, any adhesives used to bond the electrode to the overlay or enclosure, and any transition materials used to remove air gaps between the electrode and the overlay. Mechanicals also include the types of materials used for the electrodes. The mechanicals affect both the signal and the parasitic capacitance.

The goal of this section is threefold:

To understand the benefits in terms of both aesthetics and robustness

To understand how the materials on top of the electrode and the electrode material itself influence the layout of the electrodes

To avoid mistakes in the mechanicals that are detrimental to the electrical performance

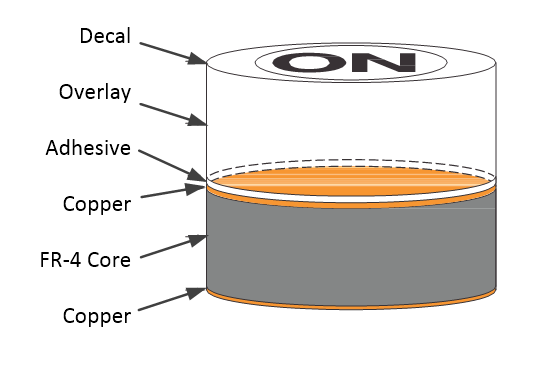

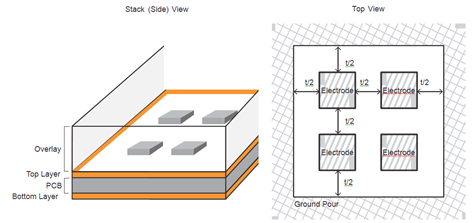

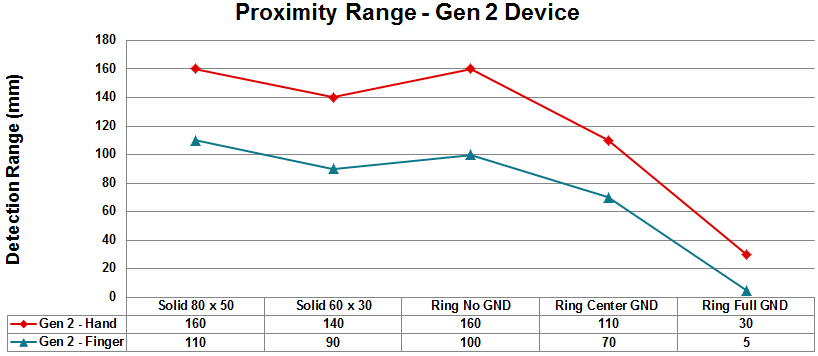

Typical Stackup¶

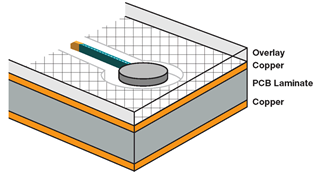

The following figure shows a typical stackup for a capacitive touch solution. One of the main goals of this stackup is to reduce (or eliminate, if possible) any low-dielectric (air) gaps between the electrode and the area where the touch takes place. The capacitance associated with the stackup has a very strong effect on the signal (change in capacitance from a touch). The signal is directly proportional to the dielectric of the materials. If possible, high-dielectric materials should be used, but at a minimum the stackup should eliminate any air gaps.

Air gaps can also contain moisture, which can influence performance or even damage the stackup as temperatures vary and the contents of the gap expand and contract.

Fig. 2 Typical Material Stackup¶

Another critical attribute of the stackup is that it should be non-conductive. This is not usually a problem with the overlay material but can be overlooked when choosing adhesives, labels, or inks. Popular adhesives for capacitive touch solutions include 200MP products from 3M™ such as 467MP and 468MP.

Overlay¶

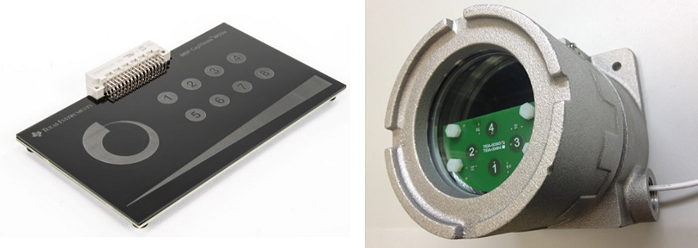

Why you want to have an Overlay?

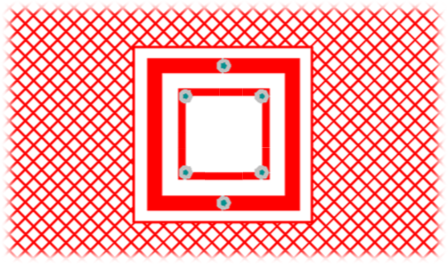

Overlays are very important part of the capacitive touch system, it allows the designers to give their product a sleek industrial design and also provide the ESD and environment protections like the pictures showing below.

Fig. 3 Overlay Purpose¶

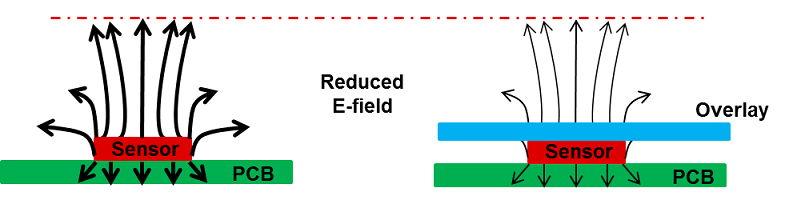

What is the trade-off?

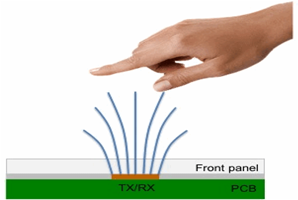

It provides many benefits to product designers by adding an overlay on top of the capacitive sensor however the benefits come with a trade-off. When an overlay is placed between a sensor and the point of contact for a finger, a sensor’s sensitivity is greatly reduced because the overlay reduces the effective electric field going out from the sensor. The dielectric constants determines how efficiently electric Field passes through material and the distance between the overlay and the sensor determines how much electric field left in target point of contact area.

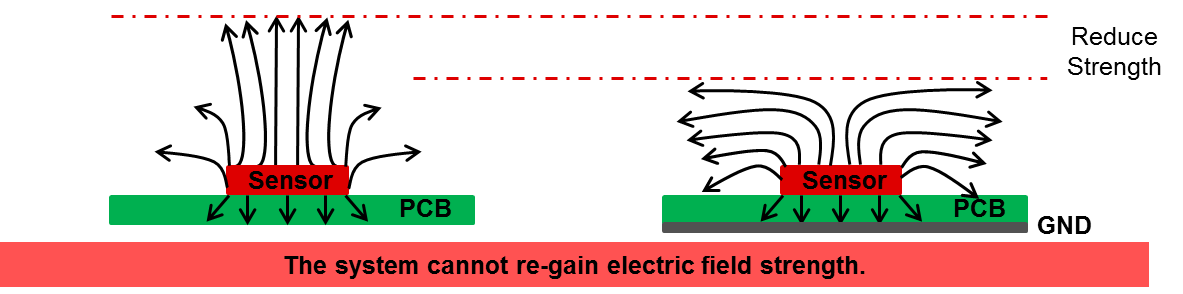

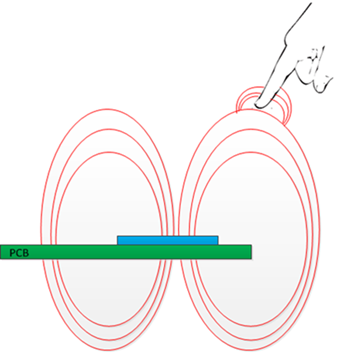

As the diagrams show below, adding an overlay over a sensor reduce the electric field going out from the sensor which reduces the strength or range of a sensor to a touch condition.

Fig. 4 Overlay Trade-off¶

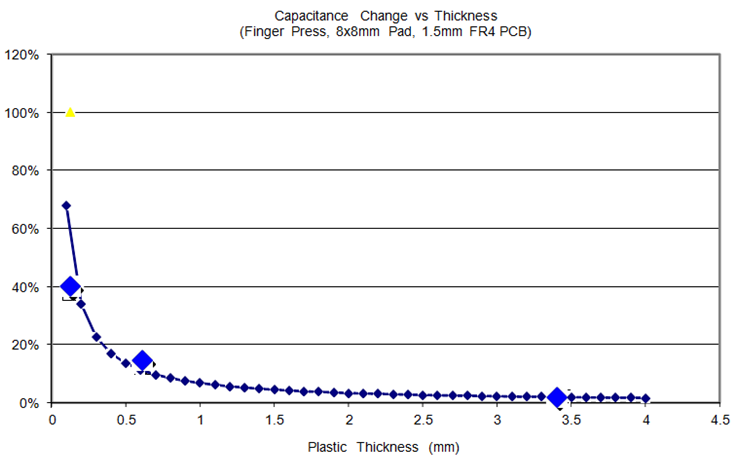

The following figure shows the relationship between the thickness of the overlay and the sensitivity of the circuit. From the parallel plate capacitance equation, the capacitance in inversely proportional to the material thickness (C ~ 1/d).

Fig. 5 Sensitivity vs Thickness¶

The thickness and dielectric of the material influence the electrode design. The electrode area is a function of the area of interaction (a fingertip or the palm of the hand) while the spacing (to adjacent electrodes or ground fill) is related to the thickness of the overlay. For example, with a 2-mm overlay that has a dielectric of 3, the spacing should be approximately 1 mm (half of the thickness). Using a higher dielectric material (for example, Er = 6) the thickness could be doubled while maintaining the same level of performance. The following table shows dielectric values for various materials used as overlays.

Material |

Dielectric Constant (Er) (1) |

Breakdown Voltage (V/mm) |

|---|---|---|

Air |

1.0 |

3300 (STP) |

FR-4 |

4.8 |

20000 |

Glass |

7.6 to 8.0 |

7900 |

Gorilla® Glass |

7.2 to 7.6 |

See Manufacturer (2) |

Polycarbonate |

2.9 to 3.0 |

16000 |

Acrylic |

2.8 |

13000 |

ABS |

2.4 to 4.1 |

16000 |

Table: Material Dielectric and Breakdown Voltage

Relative permittivity

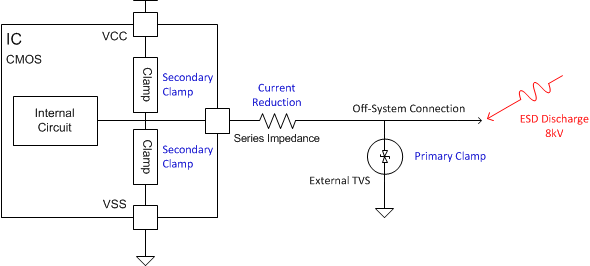

The table above also includes the breakdown voltage for different overlay materials. This should be considered when designed for ESD protection. ESD solutions should be system solutions, and any additional components should complement the protection provided by the overlay.

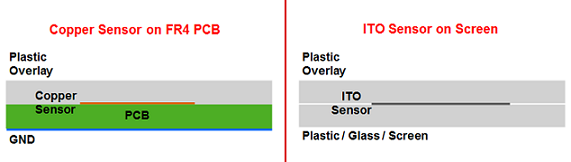

Electrode and Trace Materials¶

The performance is affected by the conductive materials that are used for the electrode and for the trace between the electrode and the microcontroller. Most applications use copper on a PCB, and copper has a resistivity of 1.7x10-6 Ohm-cm (1). As the resistivity of the conductor increases, the ability to move charge to and from the electrode decreases. This has the same effect as an increase in parasitic capacitance. This increase in resistivity, like an increase in parasitic capacitance, reduces the system sensitivity. The table below shows the resistivity for materials that are commonly used in touch applications.

Material |

Resistivity, p (Ohm-cm)(1) |

|---|---|

Copper |

1.68x10-6 |

Silver |

1.59x10-6 |

Tin |

1.09x10-5 |

Indium Tin Oxide |

1.05x10-3 (2) |

Table: Resistivity of Materials

Resistivity is given in Ohm-cm so that resistance is equal to the resistivity times the length divided by the cross-sectional area : R = p x L / A.

This resistivity is for a film thickness of 270 nm. Typically, vendors provide sheet resistance instead of resistivity for ITO, which is on the order of 10 to 100 Ohms per square.

When using high-resistivity materials, generally the recommendation is to increase the area of traces to reduce the resistance (at the cost of capacitance). ITO solutions provide lower sensitivity, which must be compensated for in the capacitance measurement algorithm by longer measurement times.

Other Situations¶

Not all applications fit into the typical category, and this section describes two special cases. The first is intentional air gaps that are greater than 2 mm between the electrode and the overlay material, and the second is the use of gloves.

Gaps¶

Why you want to have a gap?

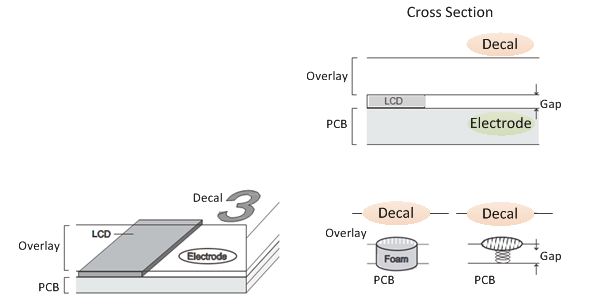

In some applications, components are on the same layer as the electrode. This prevents the overlay from being directly applied to the electrode. A common example of this is when an LCD is mounted near the electrode (see diagram below). Another scenario is when the overlay material is not a uniform surface and, therefore, the electrode cannot make direct contact with the overlay.

Fig. 6 Intentional Gaps Between Electrode and Overlay¶

What is the trade-off?

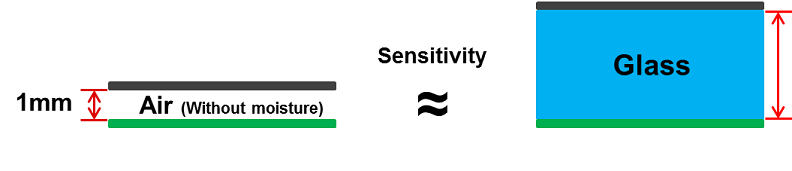

As we discussed in the Overlay section, air has really low dielectric constant and therefore does not pass the electric field very efficiently.

As the diagram shows, theoretically the sensitivity for 1mm air gap without any moisture will be similar to an 8mm thick glass. Typical dielectric values for Air is 1. (Without moisture) Typical dielectric values for Glass is 8.

Fig. 7 Gap dielectric values¶

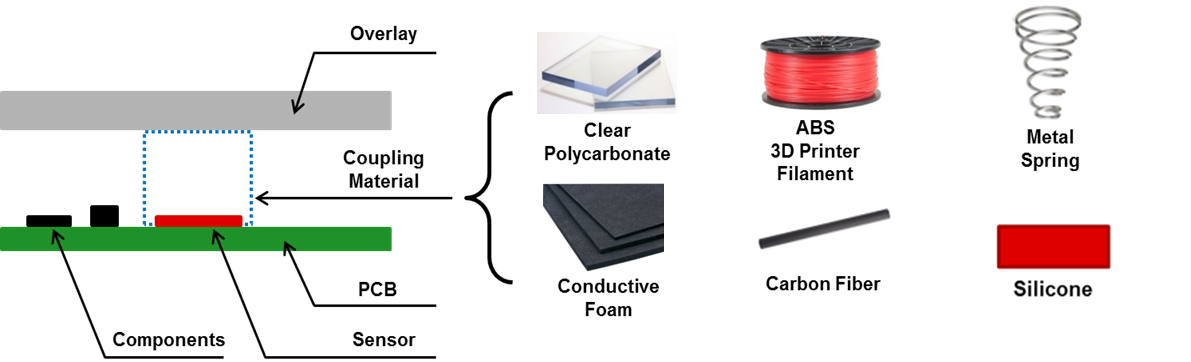

To keep the air gap without affecting too much of the sensor performance, we must bridge the gap for the sensor area with a non-conductive filler (typically adhesive) or a conductive extension. When the gap is in excess of 2 mm, then a conductive extension, either foam or metal, should be used. The metal or foam must be malleable to conform to the shape of the surfaces and prevent the formation of gaps.

When customer choice their bridge materials please take in consideration of dielectric values, transparency, mechanical support, manufacture cost, noise tolerance. The diagram below shows several materials we experimented to help to bridge the air gap and the sensitivity increase goes to an order of: Metal Spring > Conductive Foam > Carbon Fiber > Polycarbonate > ABS > Silicone

Fig. 8 Gap Bridge¶

In either case, the gap must be filled or bridged with a non-conductive filler (typically adhesive) or a conductive extension. When the gap is in excess of 2 mm, then a conductive extension, either foam or metal, should be used. The metal or foam must be malleable to conform to the shape of the surfaces and prevent the formation of gaps. As shown in the Figure above, the area created by the foam or metal in contact with the overlay is now the area that influences the capacitance.

Gloves¶

Gloves are simply another layer of medium between the electrode and the finger, and the same principles of thickness and dielectric apply. The challenges with glove applications include the ability to support both gloved and ungloved hands as well as the variation in the types of gloves the application might require. Typical leather or plastic gloves have a dielectric constant in the range of 2 to 4, and fabric gloves and gloves with insulation can have a dielectric constant less than 2.

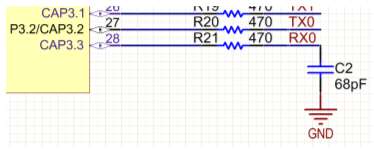

Common Layout Considerations¶

After the mechanicals are understood, the electrodes can be sized and designed to provide the most signal. Independent of the mechanicals, the layout design is affected by the distance between the microcontroller and the electrodes, the PCB stackup (for example, one layer, two layer, or four layer), and other electrical circuits on the PCB.

The first item to consider relates to the schematic and the placement of any external components that are associated with the capacitive touch solution. A typical example is ESD protection components such as a series current limiting resistor. In all cases, the components should be kept as close as possible to the microcontroller. As the components move farther away from the microcontroller, the increased area correlates to an increased risk of noise or ESD conducting into the device.

Routing¶

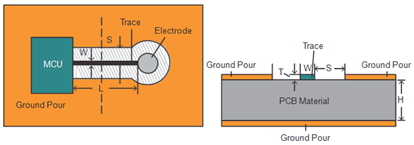

The parasitic capacitance of the trace comprises several major and minor capacitance contributors. For simplicity, C_trace represents the major capacitances formed between the trace line and the ground pour on the bottom side and surrounding it. The top and cross-sectional views of a typical two layer PCB are shown in Figure 6. The capacitance, C_trace, is determined by the trace line width (W), dielectric thickness (H), trace thickness (T), and the relative permittivity of the PCB material (Er).

Fig. 9 Top and Cross-Sectional Views of Trace Line in PCB¶

The capacitance per unit length of the trace is an important concept to emphasize the need for short traces. Increasing the distance of the trace increases the parasitic capacitance associated with the trace. Increasing the trace length can also increase susceptibility to noise. Therefore, the trace routing between the microcontroller and the electrode should be kept as short as possible. This is not always possible, so it is important to understand the increase in parasitic capacitance associated with the trace routing.

Capacitance per Unit Length¶

The capacitance per unit length should be kept as small as possible to minimize the parasitic capacitance (C_trace) and ultimately maximize sensitivity. As previously mentioned, the dominant capacitance in C_trace is the parallel plate capacitance between the trace and the surrounding ground pour. The ability to reduce this capacitance is a direct function of the PCB manufacturing capabilities. Tighter tolerances and smaller minimum dimensions (trace width and separation) allow for thinner traces and larger separation, which result in lower capacitance per unit length. These manufacturing capabilities typically come at a higher cost.

The table below shows how the capacitance per unit length changes with the variation of different dimensions. These values are taken from Reference Section in the Coplanar Waveguide Analysis/Synthesis Calculators.

W (mm) |

S (mm) |

T (mm) |

H (mm) |

Er |

C (pF/cm) |

|---|---|---|---|---|---|

0.152 |

0.152 |

0.036 |

1.6 |

4.6 |

0.633 |

0.152 |

0.254 |

0.036 |

1.6 |

4.6 |

0.555 |

0.152 |

0.381 |

0.036 |

1.6 |

4.6 |

0.496 |

0.203 |

0.152 |

0.036 |

1.6 |

4.6 |

0.692 |

0.203 |

0.254 |

0.036 |

1.6 |

4.6 |

0.602 |

0.203 |

0.381 |

0.036 |

1.6 |

4.6 |

0.543 |

0.254 |

0.152 |

0.036 |

1.6 |

4.6 |

0.740 |

0.254 |

0.254 |

0.036 |

1.6 |

4.6 |

0.641 |

0.254 |

0.381 |

0.036 |

1.6 |

4.6 |

0.578 |

0.254 |

0.152 |

0.036 |

2.54 |

4.6 |

0.736 |

0.254 |

0.254 |

0.036 |

2.54 |

4.6 |

0.637 |

0.254 |

0.381 |

0.036 |

2.54 |

4.6 |

0.566 |

Table: Calculating Results of Capacitance per Unit Length

The table above shows that increasing the space, S, between the trace line and the ground is an effective way to reduce the parasitic capacitance. However, increasing the separation can have negative effects that need to be understood. One effect is simply increased board space. Increasing the dimensions can lead to larger PCBs and higher cost. Another effect is related to noise. The larger separation makes traces more sensitive to touch events (touching the trace instead of the electrode) and more susceptible to radiated emissions.

In practice, the designer should choose a balanced S value, and a value of 1/8 of the overlay thickness is typically acceptable. Additionally, a hatched ground is commonly used instead of solid fill near the trace lines to reduce the area and consequently the parasitic capacitance.

The table above also shows that as H gets smaller, the parasitic capacitance increases, which results in a decrease in sensitivity. In most applications, a two-layer PCB is used, and a standard FR4 PCB with the thickness of 1 mm to 1.6 mm is recommended. If a multilayer board is used, it is recommended to keep the H as large as possible. With complex multilayer boards (more than six layers), it is important to recognize that the absence of copper in the internal layers can cause issues and the height, H, between the top layer and the bottom may be smaller than predicted.

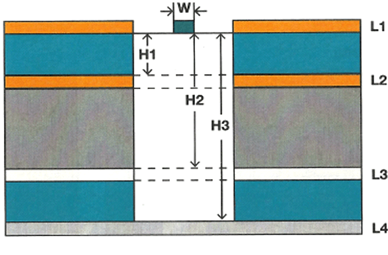

The figure below shows an example of a four-layer PCB, which may be desired in applications with limited board space. To reduce parasitic capacitance, the ground pour is usually placed on the lowest layer underneath the trace to provide the largest H. If it is difficult to achieve the maximum height, then a narrower W, a larger S, or even a hatched ground fill are alternatives to reducing the parasitic capacitance.

Fig. 10 Trace Without Copper Pouring Underneath in Multilayer PCB¶

To determine the maximum trace length from the capacitance per unit length, some additional information is needed. The following example is used to calculate the maximum distance for a trace with a capacitance per unit length of 0.58 pF/cm. The capacitance introduced by a touch, C_touch, is assumed to be approximately 1 pF. To make sure that the capacitance induced by a finger is large relative to the parasitic capacitance, the total parasitic capacitance (C_parasitics, C_trace, and C_electrode) should be in the range of 10 pF to 20 pF (the change is at least a 5% change). Assuming that the C_electrode is approximately 3 pF, the C_parasitics is 5 pF, and the capacitance per unit length is 0.58 pF/cm, so the trace line length L should be no longer than 210 mm. If the electrode is larger (for a proximity application), the capacitance itself is larger (assume approximately 8 pF for this example), so the maximum trace line length L is reduced to 120 mm.

Generally speaking, the trace width W should be as thin as the PCB technology allows, because a short and narrow trace line is preferred. The trace thickness T and the relative permittivity of the material Er also have significant influence on capacitance per unit length, but they are determined by PCB manufacture process and are usually difficult to change.

Connectors¶

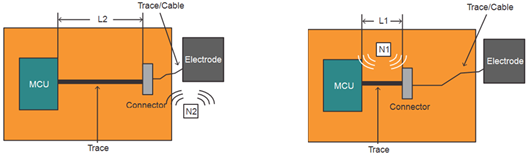

Some designs require the electrode to be off-board, and consequently a connector is used to transition the trace from the PCB to a cable or to another PCB. Connectors are generally not desired because like any component there is an associated parasitic capacitance with connector PCB footprint and structure.

In terms of parasitic capacitance and sensitivity, the connector is treated as a parasitic capacitance reducing the sensitivity of the solution. Because the connector is treated as a lumped capacitance, the placement is irrelevant to the sensitivity. However, the placement is important with respect to noise.

The figure below shows that if the aggressor (noise source, N1) is located on the PCB, then the preferred placement of the connector is near the MSP430 microcontroller. The parasitic capacitance associated with the connector shunts high-frequency noise (Z 1/jwC) and increases the noise immunity of the circuit. Conversely, if the aggressor is located off-board (noise source, N2), then the connector should be placed farther from the microcontroller and closer to the electrode. This arrangement minimizes the off-board trace and cable length (which acts like an antenna). When multiple aggressors exist as is shown in the figure below, it is recommended to reduce the effect of the radiators that most closely match the operating frequency of the touch detection circuit.

Fig. 11 Top View of Connector and Noise Source¶

When deciding the position of the connector, the designer must balance the length of the trace and the cable while considering parameters like the background noise.

Routing Material¶

The routing is typically done with copper, but other materials like silver and ITO can be used. Silver is similar to copper and similar performance can be expected (if the thickness of the materials are also equivalent). ITO is very different from copper, and the difference in resistivity degrades the sensitivity of the solution. Lowering the impedance of the trace (by increasing the width) should be a high priority in the design, even though this comes at the cost of increased parasitic capacitance and reduced noise immunity. Ultimately, the use of materials like ITO requires more processing by the MSP430 microcontroller to adjust to lower sensitivity and increased noise.

Electrode Material¶

As discussed in the Routing section, conductivity becomes an issue in more resistive materials like ITO. Although the transparency of ITO is very good, the resistivity is high when compared to materials like silver and copper. Typically the physical dimensions prohibit increasing the area of the ITO electrodes, and therefore any degradation in sensitivity must be compensated for in the firmware. This typically results in slightly longer measurement times and consequently increased power consumption.

Electrode Design¶

The electrode design must accomplish two goals. First, the design must provide sufficient signal (change in capacitance with interaction). The design must project the e-field up and out so that the appropriate level of sensitivity is achieved at the desired distance. Understanding the stackup, thickness and dielectric, the electrode can be sized and shaped to provide the maximum signal. Second, the electrode design needs to have a minimal parasitic capacitance.

In the following sections the shape and area of the electrode are discussed with the intent of maximizing the signal for different implementations (buttons, sliders, and wheels). The basis for controlling the parasitic capacitance is common to different sensor implementations and is discussed here.

The figure below shows an example PCB cross-section and the important parameters that influence the parasitic capacitance. The height, width, and separation have a direct effect on the parasitic capacitance of the electrode, C_electrode. The fundamental parameter area is not shown in the figure below because this has a direct effect on both the touch capacitance (C_touch) and the parasitic capacitance (C_electrode). This section describes how changes to the height and separation can minimize the parasitic capacitance. The following sections describe how changes to the area can maximize C_touch.

Fig. 12 Capacitance of the Electrode¶

The separation (S_electrode) is directly related to the height of the overlay as described in the Mechanical section. The height is a function of the PCB and is not a parameter that can be easily controlled. The separation is typically the parameter with the most flexibility.

Area(mm2) |

Height(mm) |

Description |

Separation(mm) |

Capacitance(pF) |

|---|---|---|---|---|

10x10, FR-4 (Er = 4.4) |

1.572 |

2 Layer PCB, L2 |

0.508 |

3.3 |

10x10, FR-4 (Er = 4.4) |

1.572 |

2 Layer PCB, L2 |

1.02 |

3.2 |

10x10, FR-4 (Er = 4.4) |

1.572 |

2 Layer PCB, L2 |

1.52 |

3.1 |

10x10, FR-4 (Er = 4.4) |

1.30 |

4 Layer PCB, L2 |

0.508 |

3.8 |

10x10, FR-4 (Er = 4.4) |

1.57 |

4 Layer PCB, L3 |

0.508 |

3.3 |

Table: Baseline Electrode Capacitance

The table above shows that increasing the height (the distance between the electrode and the reference plane) decreases the capacitance. By decreasing the parasitic capacitance, the relative change in capacitance caused by a touch event is increased. For example, if the change in capacitance associated with a touch is 0.5 pF, the relative change is greater when the base capacitance is 11 pF instead of 12 pF, (4.5% instead of 4.2%).

Spacing Between Electrodes¶

By default, the CapTIvate™ Software Library drives non-actively scanned electrodes to ground allowing neighboring electrodes to be treated as an extension of the ground pour. Therefore, the spacing between the electrodes follows the same rules for spacing from ground. The goal is provide enough spacing so that the e-field propagates up and through the overlay material. A minimum spacing of one-half the overlay thickness has been found to provide sufficient signal (sensitivity). For example, a 3mm overlay material would suggest a minimum spacing of 1.5mm or greater between electrodes or between electrodes and ground. Note, for overlay thickness less than 2mm, maintain the spacing to no less than 1mm.

Shapes¶

The capacitance of the electrode is a function of area, but the shape is important to consider, because the shape can influence the area. An important detail of designing the electrode shape is not to design shapes that have low surface area. The area of each electrode must provide the maximum C_touch, which in turn produces the most signal (the change in capacitance) when a touch event occurs.

Crosstalk¶

In the Connectors section above, the aggressor is assumed to be a point source of noise. In this section, the aggressors are different signals that are routed in close proximity to the capacitive touch sensor trace. These aggressors can be another capacitance sensor trace or non-capacitance sensor lines. Examples of non-capacitance sensor lines include digital signals, analog signals, and high-current signals used to drive LEDs.

Adjacent Capacitive Touch Signals¶

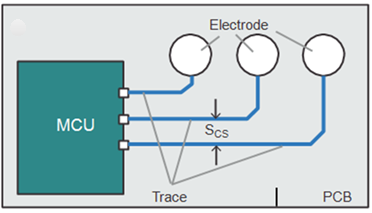

Capacitive sensor traces influence neighboring capacitive touch sensor traces. The space between capacitance sensor trace lines, Scs, should be kept as a safe distance (see figure below).

Fig. 13 Trace Spacing¶

Digital Signals¶

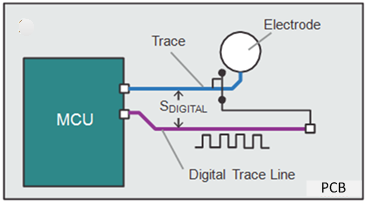

Digital signals are typically PWM signals or communications like I2C or SPI. Unlike the capacitive traces, these signals can act as aggressors and can be active during a capacitance measurement. It is recommended to keep these types of signals at least 4 mm away from the capacitive touch trace. If the digital signal and the capacitive touch trace must cross, then it is recommended to keep the crossing at a 90 degree angle.

Fig. 14 Digital Traces¶

LEDs/LED Backlighting¶

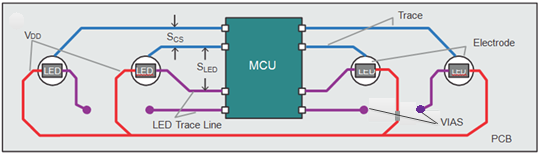

Signals used to drive LEDs (unless the LEDs require high-strength drivers) are similar to other digital signals. As with digital signals, a distance of at least 4 mm is strongly recommended for S_LED as shown in the figure below.

Fig. 15 LED Traces¶

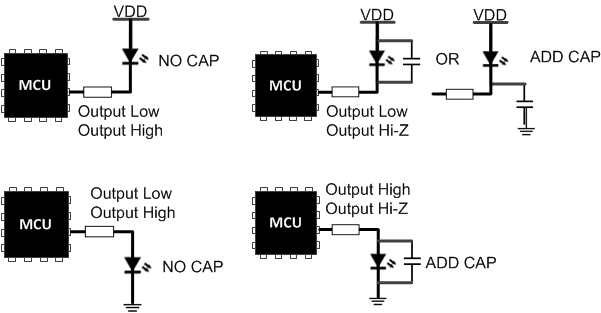

As a general rule, LEDs should be driven and the use of high-impedance states should not be used to control the LED. The use of a high impedance to prevent an LED from conducting can result in a significant difference between the on-state and off-state capacitances. This change in capacitance may be detected by the touch solution and treated as a change in the system capacitance, or even worse as a false detection. If the use of high-impedance control of the LED is unavoidable, a discrete capacitor (typically 1 nF is acceptable) in parallel with the LED is recommended.

Avoid tri-stating the LED as the LED capacitance will change when turned on and off

If LED must be tri-stated, add small bypass capacitor to control change in LED capacitance

Capacitor does not have to be physically near LED, just in the circuit

Fig. 16 Recommended methods to drive LEDs¶

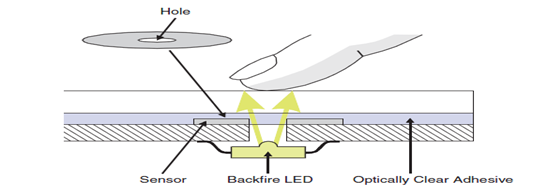

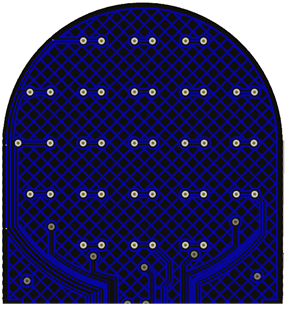

LED BackLighting can be done easily using a back lighting LED on the opposite side of the PCB

Keep hole as small as possible to eliminate possible dead spots in sensor

LEDs may require bypass capacitor (see above)

Fig. 17 Backlighting LEDs¶

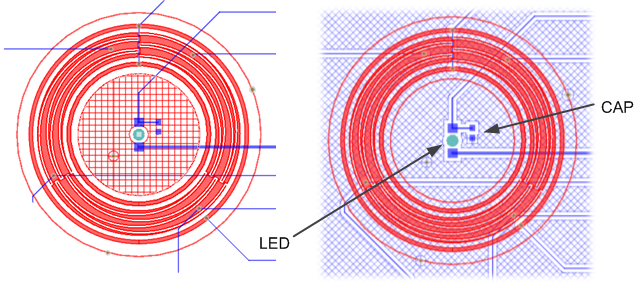

As an example of an LED backlighting technique, the following wheel design has an LED mounted on the backside of the PCB and illuminates through a small hole. In parallel to the LED, a small 1nF capacitor is used to reject changes in capacitance when the LED is switched between ground and high-Z. Also note the hatched ground on both the top and bottom layers to help with noise immunity.

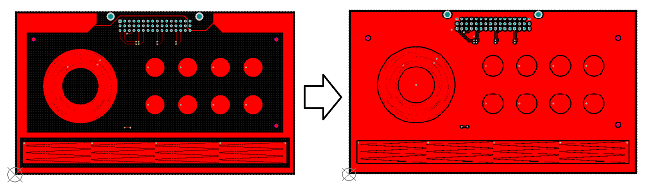

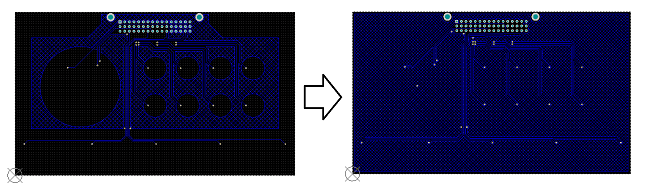

Fig. 18 LED BackLight Example¶

Ground Planes¶

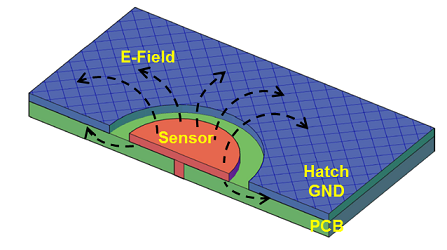

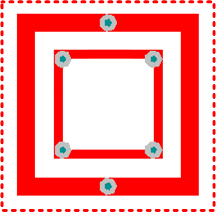

Why you want to have a Ground pours around the sensors?

Ground planes have a purpose by helping with noise immunity and cross-talk between neighboring sensors. Although generally recommended, the amount of fill (solid vs a hatched) depends on the system environment.

Fig. 19 Ground Pours¶

What are the trades-off?

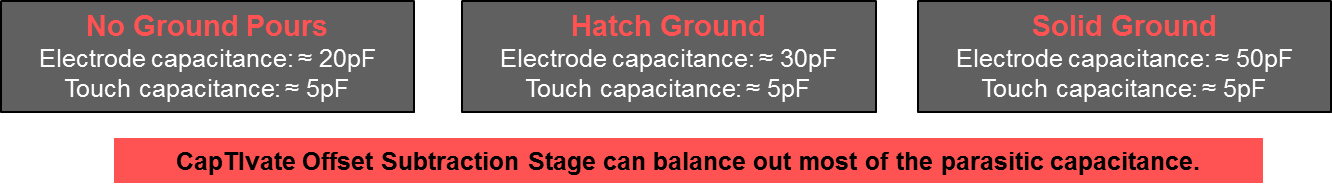

Parasitic capacitance

The ground pours add the parasitic capacitance into the base capacitance as the separation from the ground decreases and the area of the ground pour increases. As shown in the illustrations, adding a hatched or solid ground pour will increases the total sensor capacitance, making it less sensitive to the small change in capacitance caused by a touch condition. Fortunately the CapTIvate peripheral has the ability to subtract off these parasitic effects, restoring a sensor’s sensitivity.

Fig. 20 Ground Pours Parasitic Capacitance Trade-off¶

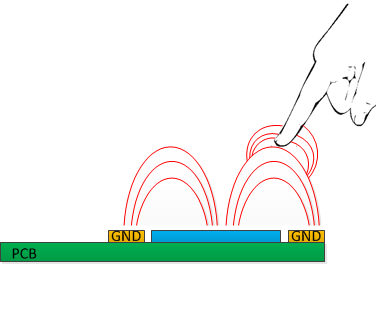

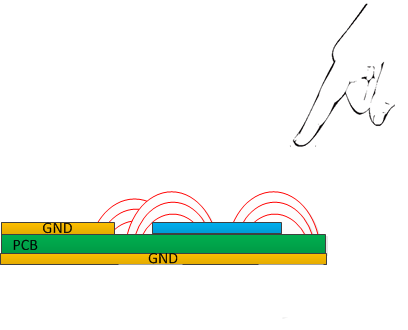

Electric field

These same ground pours can also have a negative effect by pulling the sensor’s electric field towards the ground pour, creating a potentially large parasitic capacitance. This parasitic capacitance degrades the overall strength of a touch signal, making the sensor less sensitive to a touch condition. As shown in the illustration, more of the sensor’s electric field lines are attracted to the ground pour rather than extending outward from the sensor. This effectively reduces the strength or range of a sensor to a touch condition. However, the system cannot re-gain the electric field strength.

Fig. 21 Ground Pours Electric Field Trade-off¶

Planes and pours near the electrode and trace must be connected to a potential and cannot be left floating or in a high impedance state. Such structures serve as a mechanism for noise coupling and are strongly discouraged.

Separation¶

Ground planes, both coplanar and on neighboring PCB layers, reduce noise. This is the same principle discussed in the Routing section. The ground or guard structures are placed as close as possible to reduce noise but also kept far enough away to minimize parasitic capacitance. This separation is a function of the thickness of the materials (overlay, adhesive, etc.) on top of the trace. As mentioned in the Routing section, a good rule is one-eighth the thickness for separation between traces and ground. The separation between electrodes and ground should be at least one-half the thickness.

Fig. 22 Ground Separation¶

As shown in the figure above, the separation between the electrode and the coplanar ground pour should be at least one half the thickness of the overlay material. Any unused electrode should be held at a logic low level (Vss potential) and not allowed to float. In this way the spacing between electrodes is the same as the ground and electrode distance.

Pour¶

The use of a hatched pour instead of a solid ground pour is a good design practice. This reduces the area and consequently the parasitic capacitance associated with both C_trace and C_electrode. Typically, a 25% fill hatch is sufficient, but this percentage can be increased or decreased to improve noise immunity or sensitivity, respectively.

Fig. 23 Example Hatched Ground Fill¶

Using Poly Cut Out to control Ground Pour around Sensors¶

When designing a button, slider or wheel of any size or shape, a flexible method to control the distance between any sensor and the ground pour is to provide a poly cut-out region around the sensor as shown below.

Fig. 24 Define Poly Cut Out Region¶

Fig. 25 Ground Pour Spacing Controlled¶

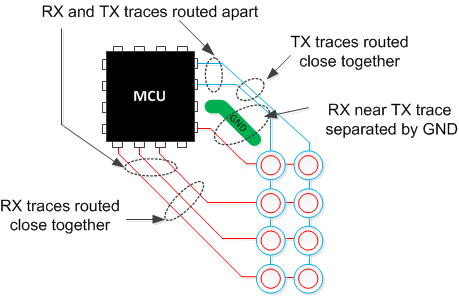

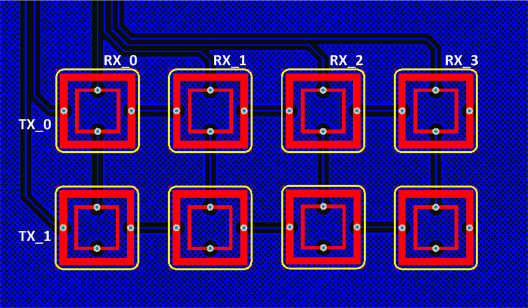

Mutual Capacitance Traces¶

Routing mutual capacitive traces has special considerations compared to self capacitive traces. Specifically, the TX and RX signals on the same layer should be close only in those areas where coupling through a finger touch is expected by design, such as the case with button, slider or wheel elements (electrodes). Anywhere else that TX and RX traces on the same layer are routed close can be susceptible to a “ghost” touch should a finger touch in that area.

Traces¶

Avoid routing TX lines near RX lines when possible

Within a finger spacing, they will create a button

If unable to avoid on same layer, put ground trace in between (adds parasitic capacitance)

If TX needs to cross RX, make crossing perpendicular (minimize surface area intersection)

Avoid running TX on one layer of PCB parallel to RX on other layer of PCB

Route TX lines next to other TX lines

Route RX lines next to other RX lines

Keep nearby ground away from TX and RX traces by 1/2 panel thickness (reduces parasitic capacitance)

The diagram below shows an 8-button keypad using (2) TX and (4) RX traces. In this layout the TX and RX traces are on the same layer. The TX traces are routed close to each other as are the RX traces. The TX traces are routed away from the RX traces. In this example there is one RX that must be routed near a TX trace. A ground trace/fill is used to separate the RX and TX traces.

Fig. 26 Routing mutual capacitance sensors¶

Electrodes¶

For noise suppression, use 25% hatched ground on:

Bottom layer of PCB and/or

On top layer of PCB keeping ground 1/2 panel thickness away from electrode

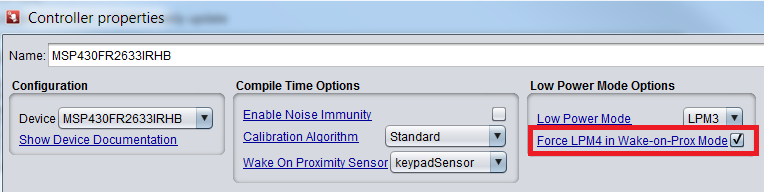

CapTIvate Pin Selection¶

It is important to consider the electrode-to-pin mapping early in the design process, as the pin selection can have significant impact on performance. The pin mapping primarily effects the following parameters:

Measurement time and power consumption, in designs with more than one electrode

Parasitic capacitance, in designs using mutual capacitance

Signal crosstalk, in designs where digital port pins are switching near the CapTIvate pins.

CapTIvate Pin Nomenclature¶

CapTIvate pins are named CAPx.y on a device datasheet and in the CapTIvate Design Center. In this scheme, ‘x’ refers to the CapTIvate block the pin is connected to, and ‘y’ refers to the ID of the pin on that CapTIvate block. A CapTIvate block is a capacitance-to-digital conversion engine, and many CapTIvate devices have multiple blocks to enable parallel measurement of multiple sensors, reducing measurement times. For example, let’s consider a design with two buttons. On an MSP430FR2522 MCU, we could connect those two buttons to the same block or to two different blocks. If we connected both buttons to CAP0.x (say, CAP0.0 and CAP0.1), then we would have to measure them sequentially (one after the other) since they both share the same measurement engine. However, if we would have connected them to CAP0.0 and CAP1.0, we would have been able to measure them at the same time- resulting in half the measurement time. This reduction in measurement time gives the flexibility of being able to reduce power consumption or increase the scan rate to improve the responsiveness of the sensors.

Electrode to Pin Assignment Procedure¶

To obtain an optimum routing, it is recommended to either assign pins automatically (using the CapTIvate Design Center Auto-Assign feature), or manually, using the procedure outlined below.

If the design has more than one electrode (more than one button), and the device selected has more than one CapTIvate block, it is best to assign RX’s to separate CapTIvate blocks. This allows for parallel scanning, which reduces measurement time and power consumption. To determine if the device being used has more than one block, check the device family chapter.

If the design has mutual capacitance sensors, select the TX pins to be as far away as possible from the RX pins. This reduces parasitic mutual capacitance between the RX’s and TX’s, and improves sensitivity. As a general rule, it is still best to spread the RX’s out across different blocks before considering this step.

If you plan to have digital IO’s on the MCU that are switching in a frequency range similar to the electrode acquisition frequency, it is best to isolate those signals as much as possible from any RX pins to reduce noise resulting from trace crosstalk. The frequency range of concern is generally 500kHz to 4 MHz. Common offenders in this area are SPI signals and PWM signals routed near sensor RX traces.

Buttons¶

Self Capacitive Buttons¶

A self capacitive button sensor is a single electrode. Self capacitive buttons are simple to layout and each button is assigned to only one pin on the MCU. Self capacitive buttons will provide greater sensitivity as compared to a mutual capacitive button, but are more influenced by parasitic capacitances to ground.

Parameter |

Guidance |

|---|---|

Radiation Pattern |

Between Electrode and Ground |

Size |

Equivalent to interaction |

Shape |

Various: typically round or square |

Spacing |

0.5 x Overlay minimum thickness |

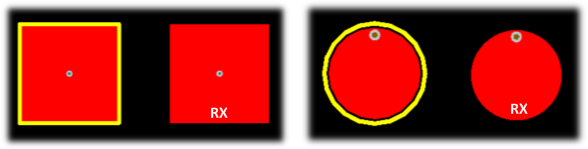

Fig. 27 Example Self Capacitive Button Designs¶

Self Capacitive Button Shapes¶

The electrode shape is typically rectangular or round with common sizes of 10mm and 12mm. Ultimately, the size will depend on the required touch area. A good design practice is to keep the size of the button as small as possible, which minimizes the capacitance and will help with the following:

Reduce susceptibility to noise

Improve sensitivity

Lower power operation due to smaller capacitance and reduced electrode scan time

In the diagram below, an example silkscreen button outline pattern is shown.

Fig. 28 Example Self Capacitive Button Designs¶

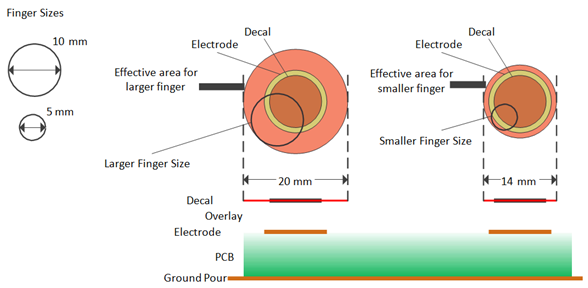

The goal of the button area is to provide sufficient signal when the user touches the overlay above the button electrode. Typically a nonconductive decal or ink is used to identify the touch area above the electrode. The relationship between the decal and the electrode can be varied so that contact with the outer edge of the decal registers a touch. Conversely, the electrode could be small to ensure that the button is activated only when the center of the decal is touched. The two figures below show how the effective touch area is a function of the electrode size and the size of the finger.

Fig. 29 Effective Area Example for Electrodes Larger Than Decal¶

Fig. 30 Effective Area Example for Electrode Smaller Than Decal¶

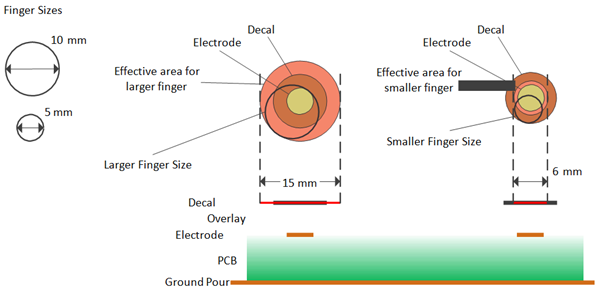

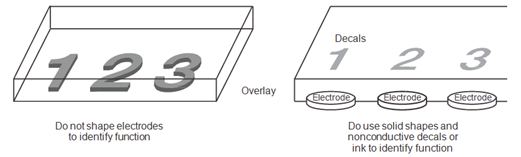

One common mistake is to make the electrode the same shape as the icons printed (in nonconductive ink) on the overlay. As shown in the figure below, this can lead to electrodes with odd shapes that create discontinuities and reduce surface area.

Fig. 31 Button Shape Examples, Dos and Don’ts¶

As the distance of the overlay increases, the effective area decreases. Therefore, it is important to keep the button electrode diameter at least three times the overlay thickness.

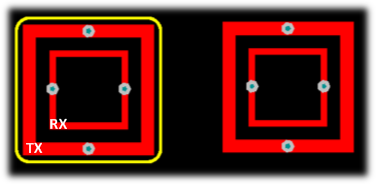

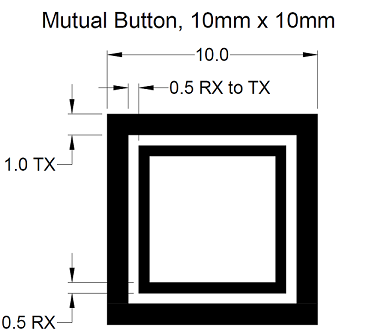

Mutual Capacitive Buttons¶

A mutual or “projected” capacitive button sensor requires two electrodes, one as a TX and the other for RX. It is possible to pack the electrodes closer together with a low risk of cross talk between neighboring electrodes. With mutual capacitive electrodes, multi-touch is also possible by multiplexing the channels. Multiplexing creates up to 64 electrode pairs or “buttons” that can be scanned using only 16 CapTIvate™ I/O pins.

Parameter |

Guidance |

|---|---|

Radiation Pattern |

Between TX and RX and ground |

Size |

Equivalent to interaction |

Shape |

Various: recommend square or shape with corners |

RX-to-TX Spacing |

0.5mm typical |

RX Thickness |

0.5mm typical |

TX Thickness |

1mm typical |

Fig. 32 Example Mutual Capacitive Button Designs¶

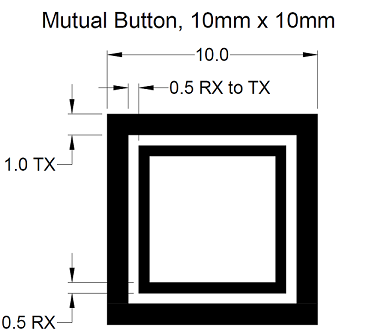

Mutual Capacitive Button Shapes¶

The electrode shape is typically rectangular with common sizes being 10mm and smaller. Ultimately, the size will depend on the required touch area. In the diagram below, the TX and RX electrodes are identified and a suggested silkscreen button outline pattern is shown. The position of the vias on the TX and RX electrodes provide flexible signal connection points when routing traces.

Simple Square Electrode

Easiest to layout

Highest sensitivity

TX on outside, RX on inside

For single layer designs, can open TX on one side and feed RX trace through (preferably not in a corner)

Better sensitivity if traces on two layers

Fig. 33 Example 10mm Mutual Capacitive Button Design)¶

A good design practice is to keep the size of the button as small as possible, which minimizes the capacitance and will help with the following:

Reduce susceptibility to noise

Improve sensitivity

Lower power operation due to smaller capacitance and reduced electrode scan time

The dimensions shown on a 10mm x 10mm example button are suitable for overlay thickness up to 2mm.

Fig. 34 10mm Mutual Capacitive Button Dimensions¶

Mutual Capacitive TX / RX Electrode Spacing Considerations¶

The RX-TX spacing is an important design parameter that affects sensitivity, measurement time, and reliability. This is because the RX-TX spacing is a key contributor to the size of the base mutual capacitance that is built in to the PCB. The closer the RX and TX are to each other, the higher the base mutual capacitance. The farther apart they are, the lower the base mutual capacitance. Having a higher base mutual capacitance improves measurement accuracy and repeatability by providing a larger RX voltage swing during measurement. However, the downside of this is that the sensitivity is reduced (because of the higher mutual capacitance, and the lower E-field propagation). TI’s recommended value for most applications is an RX-TX spacing of 0.5mm.

Fig. 35 Example Mutual Capacitive Button Designs¶

As mentioned earlier, mutual capacitive electrodes can be multiplexed with other mutual capacitive electrodes. This means that more than one button can share a common signal. In the 8-button example below, the design of the button and placement of vias allow for easy routing to the neighboring buttons. Depending on the orientation of the routing signals, the buttons could be rotated if needed. Taking advantage of CapTIvate™ Technology hardware feature allowing up to four channels to be scanned in parallel, the top four RX channels are measured while TX_0 is driven. The sequence is then repeated for the bottom row. Scanning four channels in parallel reduces the device’s overall power by reducing the scan time by 4x and it should become apparent that the eight buttons were measured with only six CapTIvate™ I/O pins.

Fig. 36 8-Button Multiplexed Mutual Capacitive Example Design¶

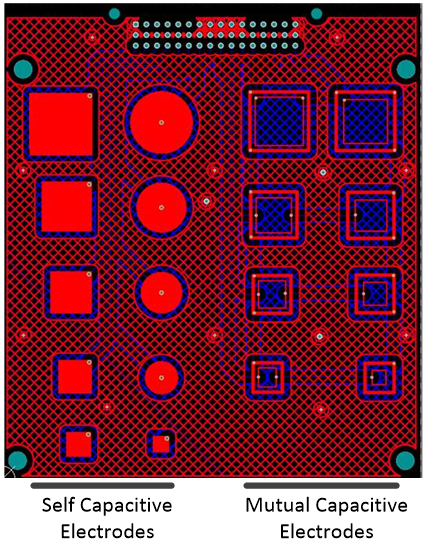

Button Performance as a Function of Overlay Thickness and Electrode Size¶

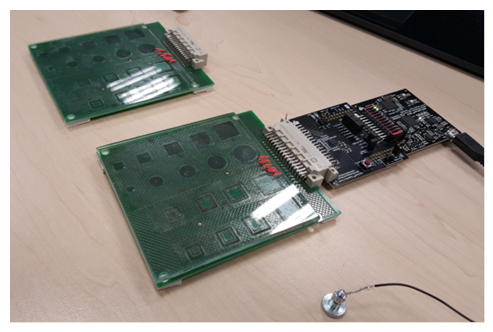

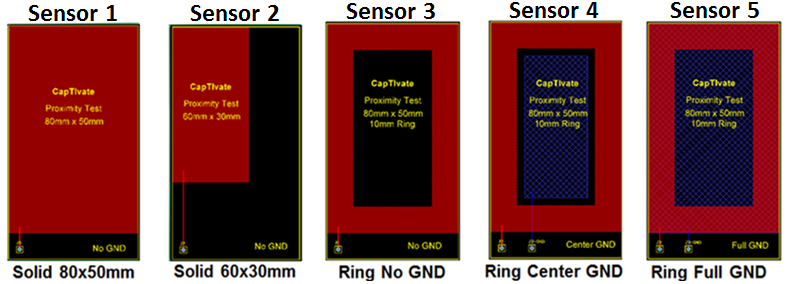

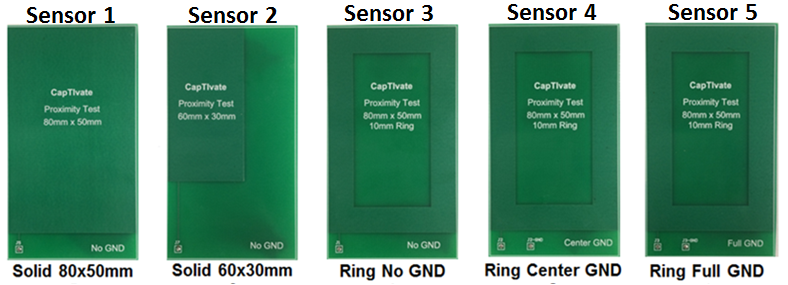

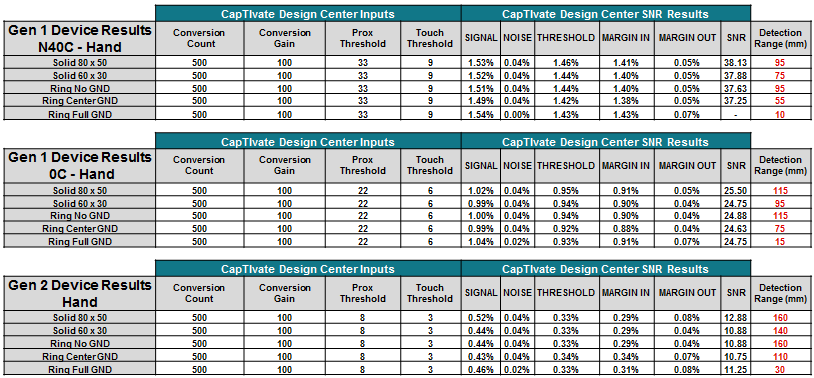

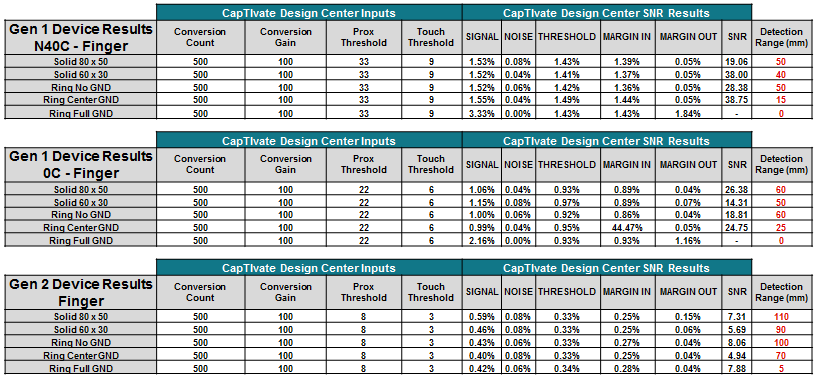

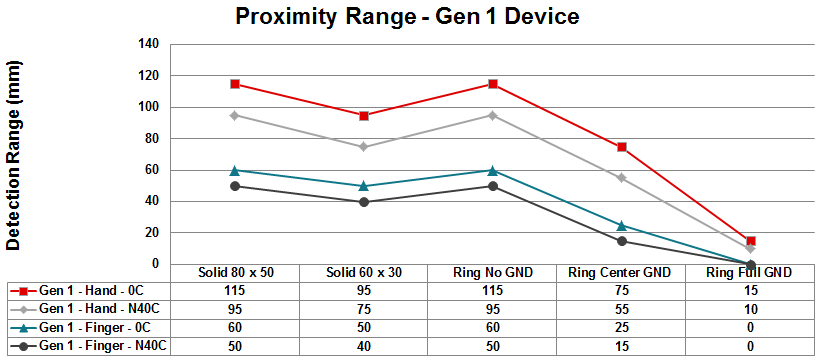

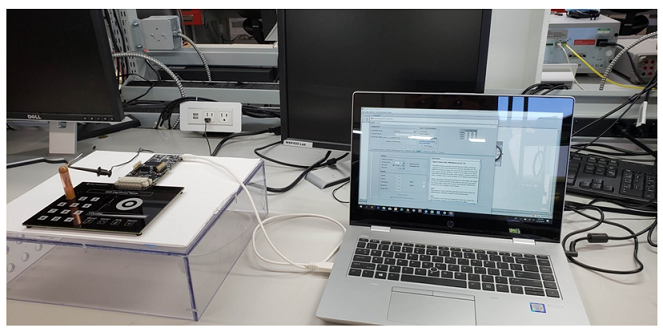

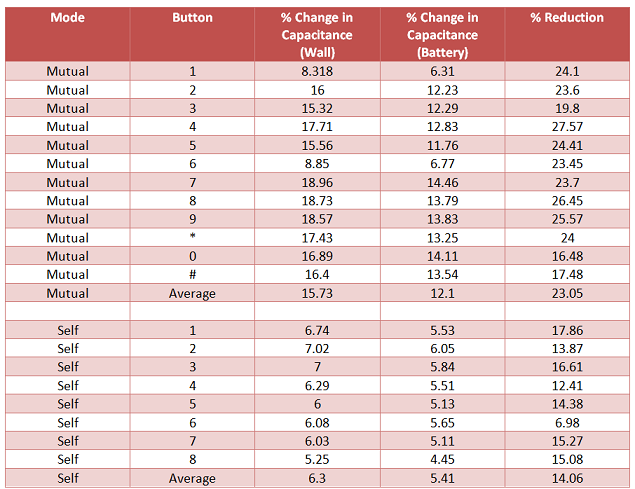

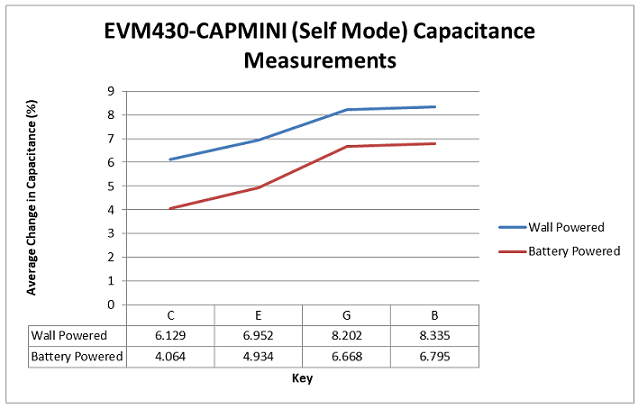

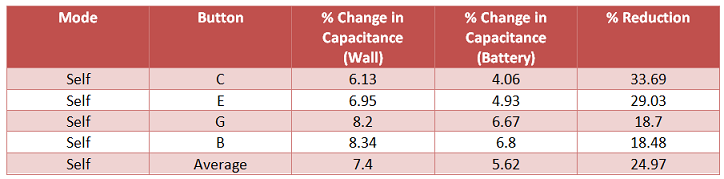

A system’s performance can depend on a variety of parameters, but those parameters that have the greatest impact are the overlay material, overlay thickness and type of electrode and electrode size. Pictured below is a test PCB electrode board containing self and mutual electrodes with different dimensions that was used to collect the data summarized in the following graphs. The graphs show the expected performance differences (signal level) for each of the different combinations.

Test Setup¶

The test PCB is a 2 layer design with ~25% hatched GND (8mil trace width, 56mil spacing) on Top and Bottom layers. The square button dimensions are 15, 12, 10, 8, 6, and 4mm. The circular button diameters are 15, 12, 10 and 8mm. The first two columns are self capacitive buttons while the other two columns are mutual capacitive buttons with RX to TX spacing is equal to 0.5mm in the third column and 1.0mm in the fourth column.

The following items were used for testing:

Material and Thickness: Glass: (4, 6) mm, Plexi Glass: (4, 6) mm

Filler material: double sided tape ~0mm

Test finger: grounded metal ring 12mm diameter

Fig. 37 Test PCB¶

Fig. 38 Test Setup¶

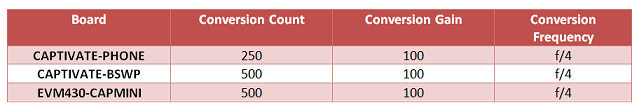

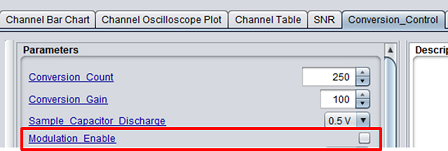

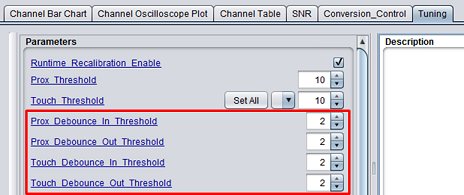

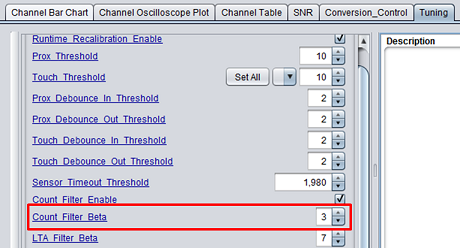

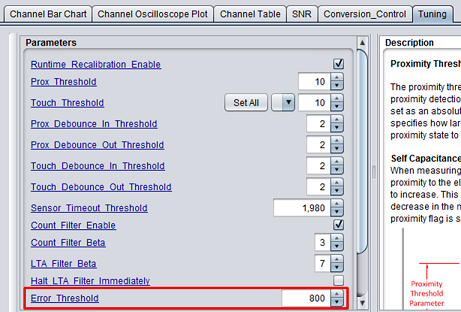

To compare results, the “Signal Strength” is expressed as percent (%) change in capacitance due to a touch, as measured using the CapTIvate Design Center SNR tool. The Conversion Count and Conversion Gain parameters are adjusted for optimal performance to cover the worst case scenarios of thick overlays and small electrodes.

For all tests the Conversion Gain is set to 100. The Conversion Counts for both Self and Mutual Electrodes are shown:

500 for 4mm glass overlay

1000 for 6mm glass overlay

1000-1200 for 4 and 6mm plexi-glass

The parameters are adjusted to allow a valid touch detection for each case. Instead of a real finger, a grounded Ø 12mm metal ring is used and placed directly on the overlay.

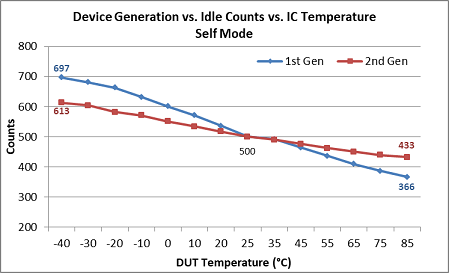

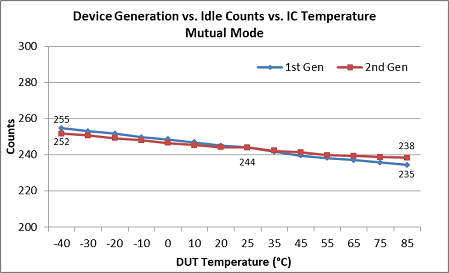

The overlays are bonded to the PCB a double sided tape, such as a 3M 467MP pressure sensitive adhesive. Depending on Gen1 or Gen2 devices, different recommended limits apply. Refer to the device family chapter for details. Additional information on the SNR tool and recommended limits can be found at Sensitivity, SNR, and Design Margin in Capacitive Touch Applications. The recommended limits are super-imposed on the graphs to help users identify the areas and conditions under which their system can operate reliable. These results provide a first assessment of the expected performance for different HW configurations during the concept phase.

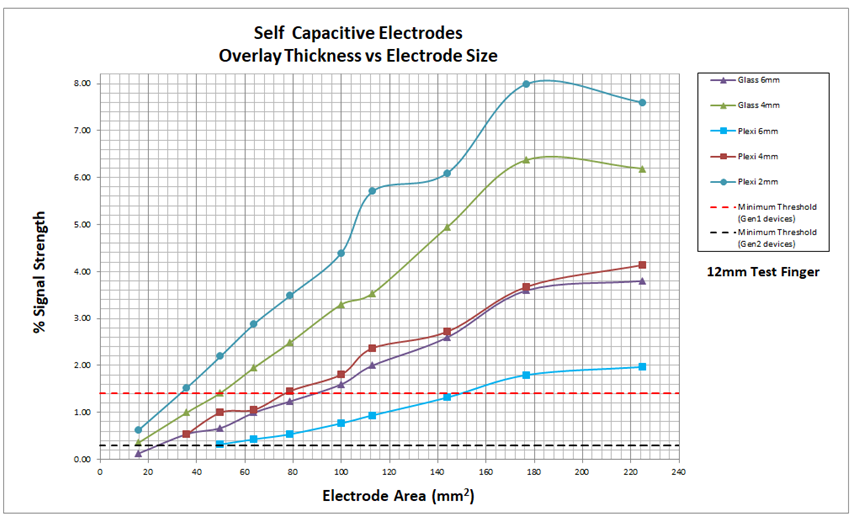

Performance Self Capacitance¶

The performance results for Self capacitance configurations can be seen in the graph below. The minimum recommended limits for Gen1 (Red limit) and Gen2 (Black limit) are given in the graph. Values above the Red line indicate a reliable operation of the system for Gen1 devices. Values above the Black line indicate a reliable operation for Gen2 devices.

For example, using a 4mm plexi glass overlay, the minimum button size for a Gen1 device is 100 mm2 (a 10x10 mm button). For the Gen2 device, the minimum button size is 36 mm2 (a 6x6 mm button).The minimum recommended threshold is based on the SNR and design margin analysis, please set the threshold accordingly based on your system design.

Fig. 39 Self Capacitive Plot¶

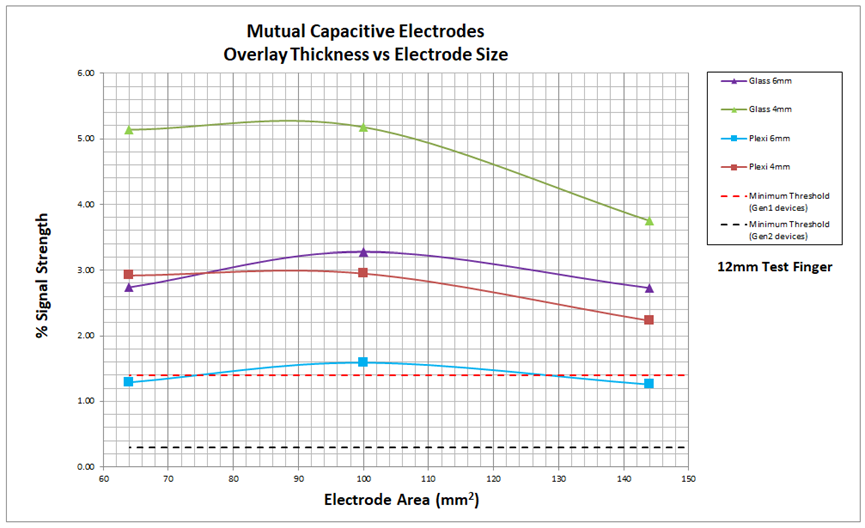

Performance Mutual Capacitance¶

The performance results for Mutual capacitance configurations can be seen in the graph below. The minimum recommended limits for Gen1 (Red limit) and Gen2 (Black limit) are given in the graph. Values above the Red line indicate a reliable operation of the system for Gen1 devices. Values above the Black line indicate a reliable operation for Gen2 devices.

For example, using a 4mm plexi glass overlay, a 10x10 mm button (100 mm2) button size will provide more than enough signal strength for both Gen1 and Gen2 devices. The flatter behavior of the curve is specific to Mutual capacitance and caused by the fact that the field is generated between the TX and RX electrode which have a fixed distance. This leads to a flat performance behavior across the different electrode sizes. The sensitivity for mutual mode is mainly depends on the overlay material, overlay thickness and the space between TX and RX.The minimum recommended threshold is based on the SNR and design margin analysis, please set the threshold accordingly based on your system design.

Fig. 40 Mutual Capacitive Plot¶

In summary, the two graphs above can help a user determine an appropriate size button and device for a given overlay thickness.

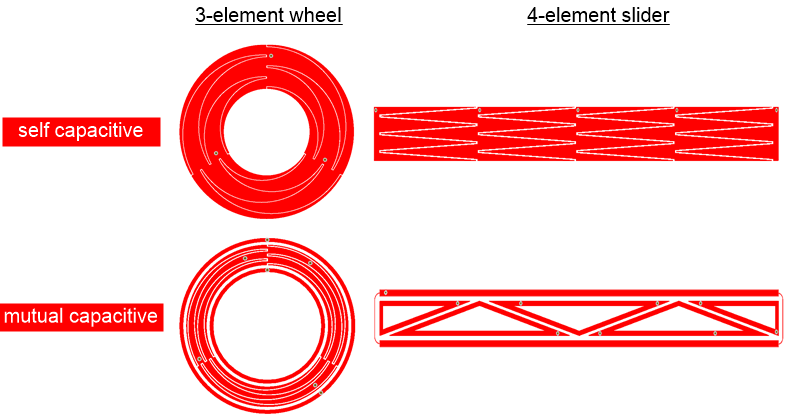

Sliders and Wheels¶

Sliders and wheels are multi-element sensors that create a linear HMI user input for such things as audio volume, LED color blending and light brightness controls. CapTIvate Software Library supports sensors ranging from 3 to 12 elements, however, more common are sliders and wheels with only three or four elements. While it is certainly possible to use more elements, the layout becomes increasingly difficult to route, requiring more CAPTIVATE IO pins and generally does not improve the sensor’s performance. Shown here are examples of self and mutual capacitive 3-element wheel and 4-element slider designs.

Fig. 41 Example - Wheel and Sliders¶

Self or Mutual Capacitive?¶

*Self*

Simple to design and route

One CAP IO pin per electrode

*Mutual*

RX elements can be multiplexed with other sensors in the system requiring fewer CAP IO pins

Creates a local e-field between RX and TX electrodes reducing cross-talk with adjacent sensors in close proximity

Better moisture rejection

How Many Electrodes?¶

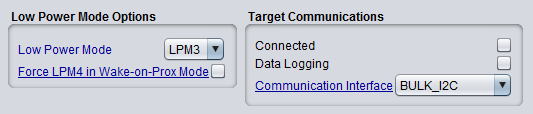

As mentioned above, most applications can implement a 3 or 4 element slider or wheel with excellent performance. One feature of CapTIvate on devices with 4 measurement blocks, such as the MSP430FR2633 and MSP430FR2676, is the ability to scan 4 elements (one element per block) in parallel in a single measurement cycle. Measuring all sensor elements in one cycle has the following benefits:

Most power efficient

Least measurement time

Best linearity

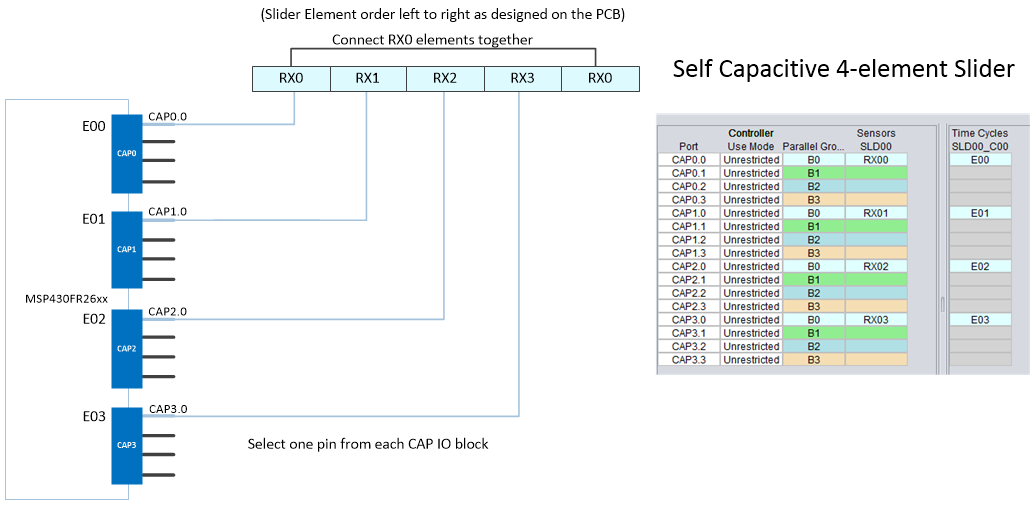

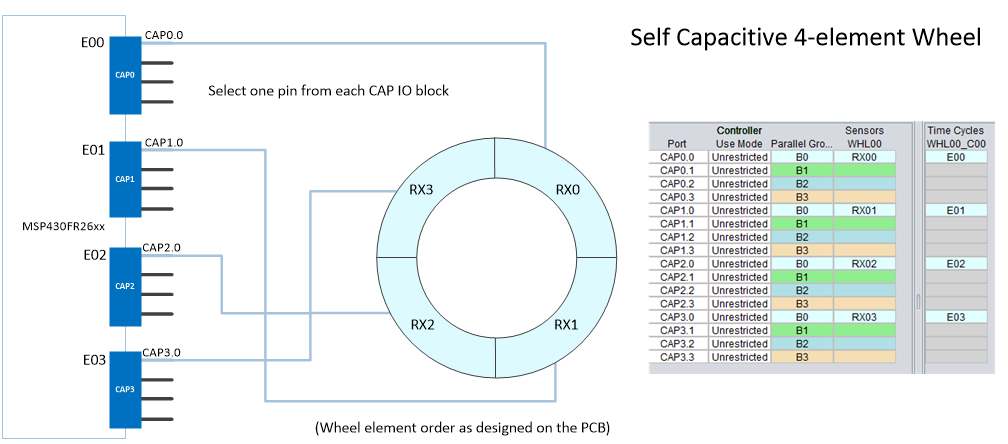

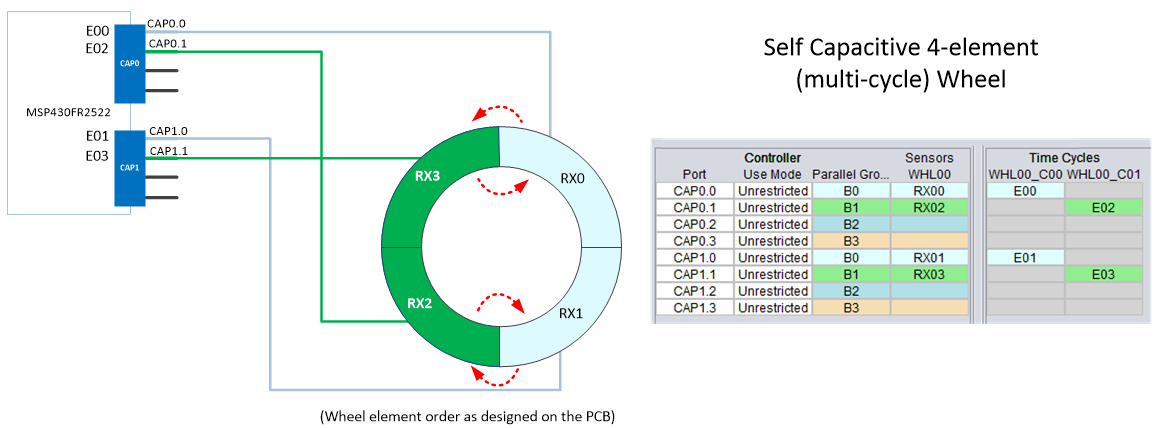

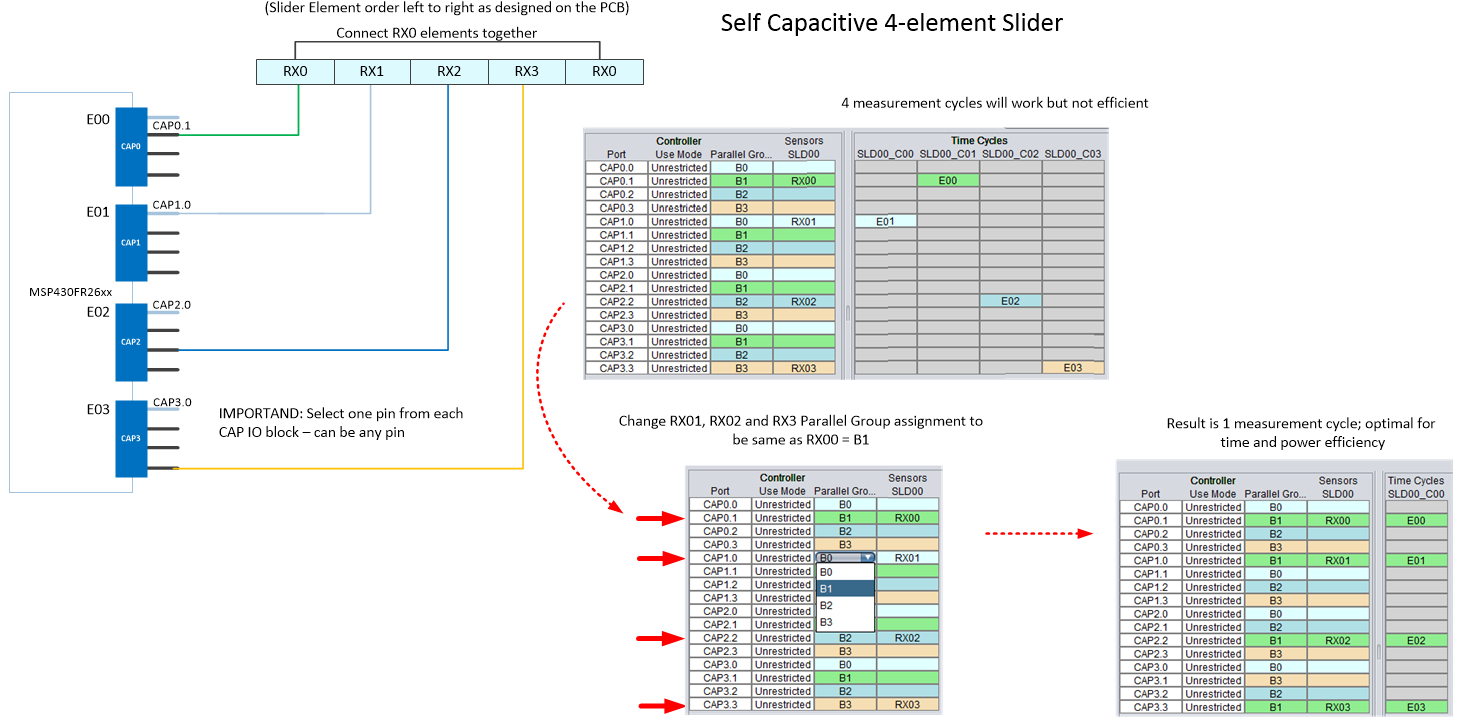

Shown here is an example of a 4-element self capacitive slider and wheel with the recommended connections selected by the CapTIvate Design Center’s “Auto Assign” button. Notice how the design center chose a configuration with each sensor element connected to only one pin from each CapTIvate measurement block. In addition, the selected pin is the first pin from each block. By default, the first pin of each block is assigned to measurement cycle 0 and is represented in the CapTIvate Design Center Sensor properties View by showing these pins (light blue) in parallel group “B0”. It is possible to manually assign pin connections and measurement cycles as described in the CapTIvate Design Center User’s Guide and discussed later in this section.

Fig. 42 Example - 4 Element Slider¶

Fig. 43 Example - 4 Element Wheel¶

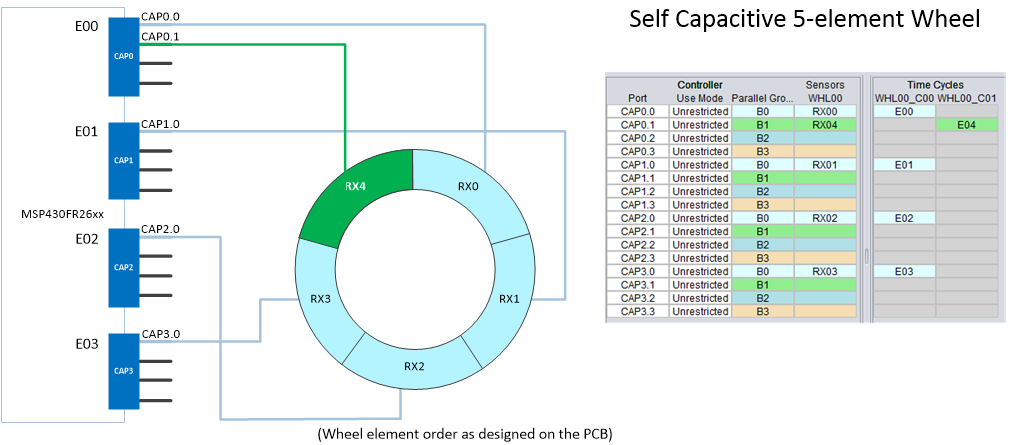

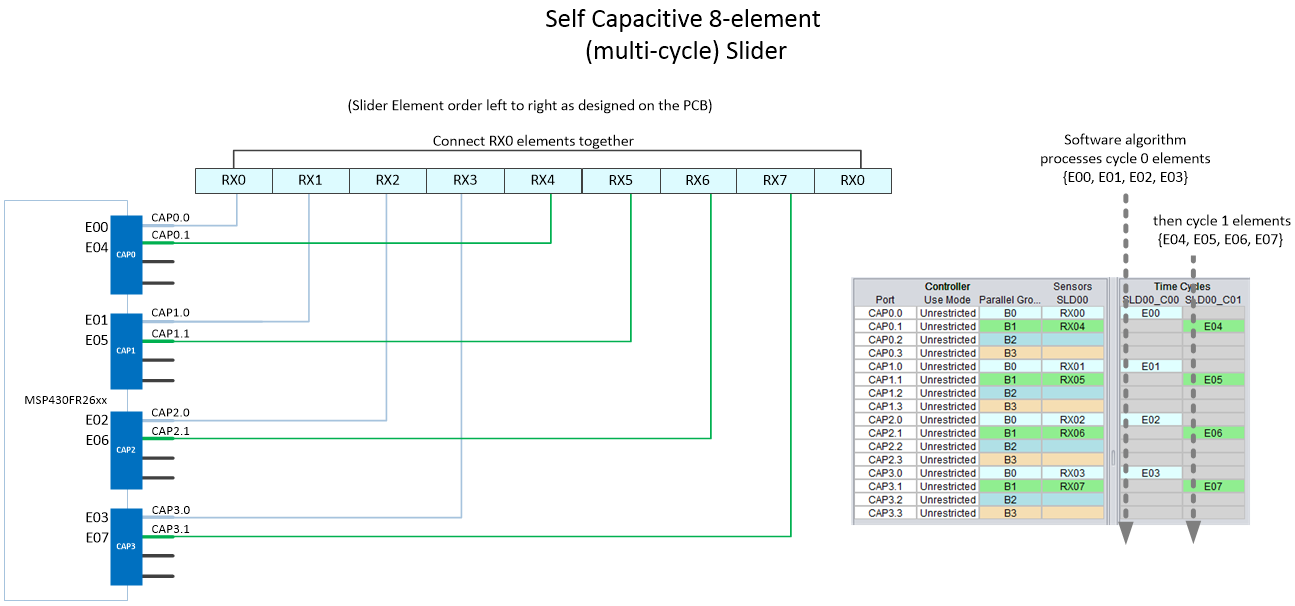

Slider and wheel sensors with more than 4-elements are supported but may not provide any additional benefits compared to the performance of a 3 or 4-element sensor. For example, sensors with more than 4-elements require additional measurement cycles, which increases the overall measurement time and increases power consumption. Shown here is an example of a 5-element self capacitive wheel. Notice the first 4-elements are measured in cycle 0 (light blue) and the 5th element is measured cycle 1 (green).

Fig. 44 Example - 5 Element Wheel¶

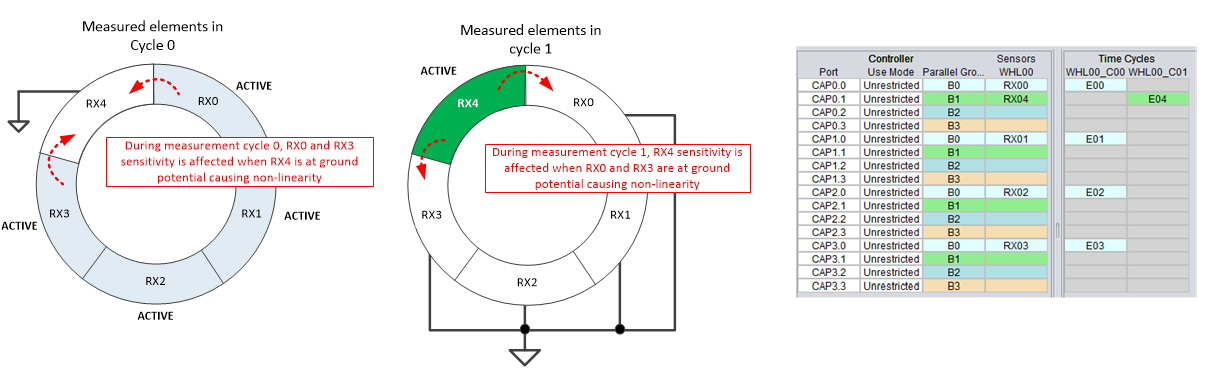

There is an additional down-side to using more than 4 elements; measuring the elements in two time cycles can influence the sensor’s linearity. Contrary to the belief that sensors with more elements will provide a better linear response is not true in this case. In this wheel example, during measurement cycle 0 (light blue) the first 4-elements are measured while the 5th element is held at ground potential. During measurement cycle 1 (green) the 5th element is measured while all of the other elements are held at ground potential. Elements at grounded potential can affect the sensitivity of their neighboring active elements resulting in a less optimal linear response.

Fig. 45 Example - 4-Block Less than Optimal Linearity¶

This same linearity issue is also true for devices with fewer than 4 blocks, such as the MSP430FR2522 with only 2 measurement blocks. Multiple measurement cycles are required, affecting the performance as described above. This is one reason why devices with fewer than 4 blocks are generally not recommended for slider and wheel applications. For best performance, consider implementing a 3 or 4-element sensor using a device with 4 measurement blocks.

Fig. 46 Example - 2-Block Less than Optimal Linearity¶

One exception to the recommendation for using no more than 4 elements might be if the wheel or slider sensor is very large, resulting in elements with a large surface area. As an element’s surface area increases, so does it’s base capacitance, reducing its sensitivity and increasing its susceptibility to conducted noise interference. Using additional elements can help by reducing an element’s baseline capacitance. However, be mindful of the trade-off as described above.

Connecting the Sensor to the MCU¶

Deciding how to connect the sensor to the MCU is traditionally driven by selecting the pins that create the most efficient PCB layout. However, in the case of CapTIvate, randomly selecting CAP IO pins is not recommended and will most likely not provide optimal performance and in many cases not work. To avoid this problem, it is strongly recommended to use the CapTIvate Design Center’s Auto Assign feature to determine the optimal connections between the sensor and the MCU. There is a specific order, as shown in the following illustrations, which the sensor’s electrodes must be connected to the CapTIvate measurement blocks for the software algorithm to properly process the measurements. If this order is not followed, the slider or wheel sensor will not work properly.

The general rule to connect a multi-electrode sensor is:

Connect first electrode to block 0

Connect second electrode to block 1

Connect third electrode to block 2

Connect fourth electrode to block 3

Selecting the same pin on each block ensures the those pins will be measured in parallel during the same measurement cycle (options to select alternate pins described later).

Fig. 47 Example - Sensor Element Processing¶

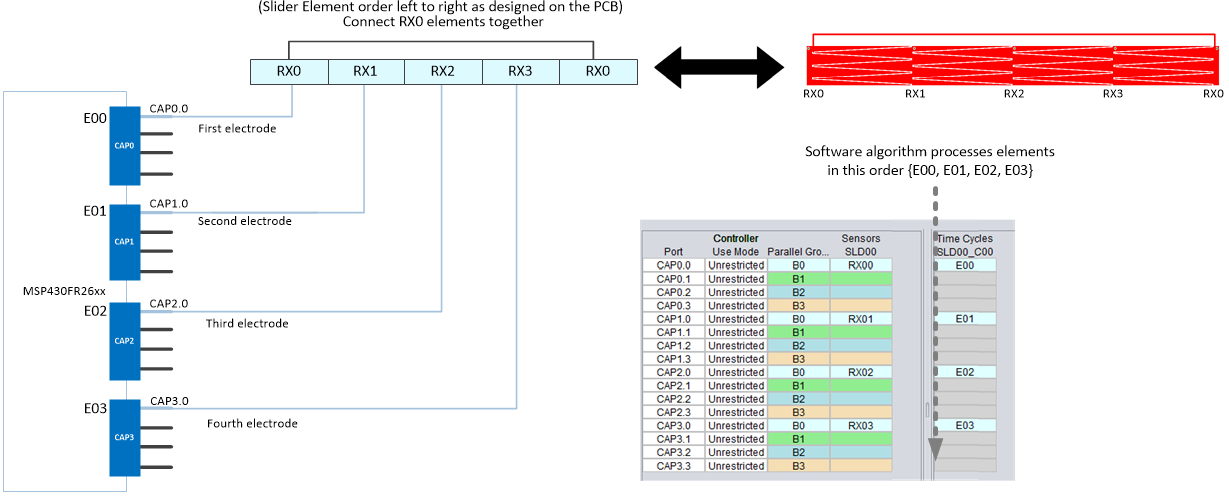

For sensor’s with more than 4 electrodes, repeat the sequence for the fourth, fifth, sixth, … electrodes as shown here in the 8 element sensor example.

Fig. 48 Example - Multi-Cycle Sensor Element Processing¶

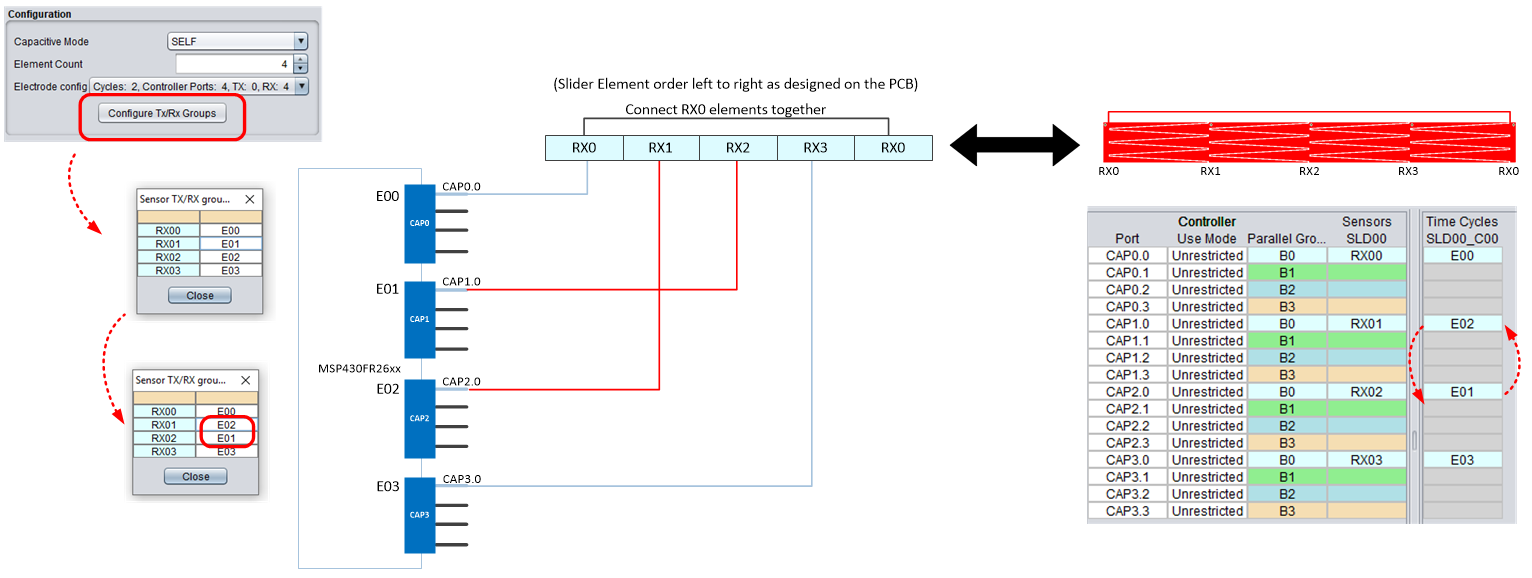

Custom Pin Assignment¶

As mentioned above, not all sensor layout designs can follow the general connection rule described above due to PCB routing restrictions. In these cases there is some flexibility to allow swapping pin assignments after the default sensor configuration has been created by the CapTIvate Design Center. In the example illustrated below, a PCB designer has determined that due to the placement of the MSP430FR2633 on the PCB it is more efficient to route traces from E01 to RX2 rather than to RX1. This breaks the general rule for pin assignments, however, in this case it is ok to connect E01 to RX2 and connect E02 to RX1 because they are in the same measurement cycle. The sensor configuration in the CapTIvate Design Center must updated to reflect this change, as shown below, else the sensor configuration in the “CAPT_UserConfig.c” will be wrong and the slider will not function properly. It is simple to make this change using a feature that allows any pin to be swapped with another pin, as long as both are in the “same” measurement cycle. Remember, this only works when the elements are in the same measurement cycle. Sensors with more than one measurement cycle cannot swap pins between “different” measurement cycles. Refer to the CapTIvate Design Center User’s Guide for more information about modifying pin connections.

Fig. 49 Example - Swapping Sensor Electrode Order¶

The majority of designs will require some customization from an initial sensor configuration or the designer may simply prefer to choose all of the pin connections manually based on the routing limitations on their PCB. This example below shows the pin connections the designer chose. The designer followed the pin assignment ordering rule and assigned the sensor’s first electrode to block CAP0, second electrode to block CAP1, third electrode to block CAP2 and finally the last electrode to block CAP3. However, instead of choosing the first pin from each block the designer chose different pins because it was more efficient to route the PCB traces between the sensor and MCU. This will work but as you can see this forces the pins into four different measurement cycles which will take 4 times longer and cause an increase in power. Fortunately there is a feature that can enable the measurement cycles (Parallel Groups) to be swapped around and put these four pins into the same measurement cycle. Notice that all of the pins are now in the same time cycle 0, parallel group B1. Refer to the CapTIvate Design Center User’s Guide for more information about modifying pin connections.

Fig. 50 Example - Manual Pin Assignments¶

Sensor Resolution¶

CapTIvate Technology’s increased sensitivity combined with the CapTIvate Software Library provide exceptional linearity and accuracy for slider and wheel resolutions well beyond 10-bit of resolution. A slider or wheel will report position from 0 to the assigned (resolution - 1). As an example, if a slider or wheel has a resolution of 1000, the sensor will report 1000 positions, from 0 to 999.

PCB Sensor Designs¶

For both sliders and wheels, the area of the electrode is not as critical as the percentage of coverage across multiple electrodes. As shown in the examples below, inter-digitated slider and wheel designs provide the most efficient and optimal coupling, but can be complicated to create. Simpler designs are possible, but require experimentation. In general, self capacitive slider and wheel sensors are more common that a mutual capacitive slider and wheel sensors.

Self Capacitive Sensor Shapes¶

To help simplify and automate the process of creating a self capacitive slider or wheel layout, See Application Note SLAA891 - Automating Capacitive Touch Sensor Design using OpenSCAD Scripts. This document describes how to create scalable self-capacitive slider or wheel sensors in seconds with OpenSCAD, a free Solid 3D CAD modeling tool and custom scripts created by Texas Instruments. There is no need to re-draw anything. Simply modify a few script parameters and a slider or wheel design can be re-scaled to any size, any number of electrodes (elements), with any spacing, and more. Designing a slider or wheel with great performance is easy.

Designing a Self Capacitive Slider¶

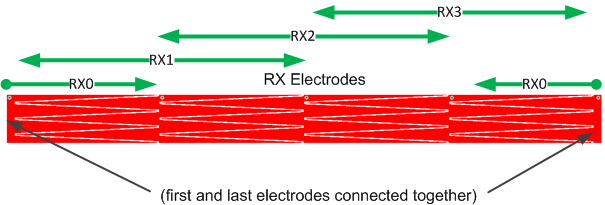

A note about connections to self and mutual capacitive sliders. Self and mutual sliders require their RX0 electrode on both ends of the slider be electrically connected on the PCB layout. This is required for the default sensor algorithm to work properly.

As alternative sensor processing algorithms are developed by TI, slider designs will be possible without this requirement. As mentioned above, a self capacitive slider with great performance can be designed with only three or four electrodes depending the size of the sensor. In fact, a 30cm slider using only four electrodes has been successfully demonstrated with superior linearity and resolution. A basic slider design below uses four RX electrodes. Each electrode is inter-digitated and the two end electrodes are electrically connected.

Fig. 51 Example 4-Element Slider Design¶

Self Capacitive Wheel¶

A wheel is basically a slider design with both ends wrapped around and connected together. With CapTIvate™ Technology, a self capacitive wheel only needs three elements to provide exceptional linearity and resolution. A basic wheel design below uses three RX channels. Each electrode is inter-digitated.

Fig. 52 Example 3-Element Wheel Design¶

Mutual Capacitive Sensor Shapes¶

Mutual capacitance has a unique feature that allows sensors to multiplexed. Mutual capacitive sliders and wheels can take advantage of this feature by sharing several RX channels with one or more sensors. Because of this, it is possible to have up to 64 electrodes using 16 CapTIvate™ I/O pins. As mentioned earlier, mutual capacitive sensor doesn’t have the same sensitivity as a self capacitive slider or wheel. However, with CapTIvate™ Technology, mutual capacitive sliders and wheels will provide the same performance as self capacitive sensors.

Mutual Capacitive Slider¶

The following diagram illustrates a four element slider. The outer TX electrode traces surround the inter-digitated RX electrodes and are connected together at both ends of the slider. This simple slider design uses four RX and one TX channels.

Fig. 53 4 Element Slider Design¶

TX on outside (track on top and bottom)

RX on inside as triangles

Spacing from TX to RX is 1/2 the overlay thickness

1st and last RX triangle connected to each other

Spacing between TX and RX ~0.5mm

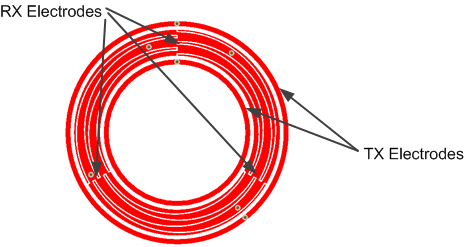

Mutual Capacitive Wheel¶

The diagram below illustrates a basic 3 element wheel design. The wheel has two TX circle electrodes surrounding the inter-digitated RX electrodes. The wheel is basically a slider design with both ends wrapped around and connected together. This wheel design uses three RX and one TX channels.

Fig. 54 3 Element Wheel Design¶

TX Circles on outside and inside of wheel (Need to connect inside and outside together on backside of board)

RX as inter-digitated patterns (similar to Self Capacitance Wheel)

Spacing between TX and RX ~1/2 overlay thickness

Ground hatch added inside wheel to provide noise stability. Also ok to have hatching on backside of board. (be careful of total ground loading

Possible to include LED/LED backlight in the center

Difficult to draw

Touchpads¶

Capacitive sensing technology is a low cost, low power HMI solution being adopted more and more in wearable and hand held products, such as earbuds, headphones, entertainment remotes and VR (virtual reality) hand controllers. The 2D touchpad is a class of capacitive sensors that provide both gesture and XY finger position. Touchpads are typically square or round, but custom shapes are possible. Hand-held products can augment their traditional button or keypad control experience with a touchpad that provides precision XY finger control using a thumb or finger. Wearable products can incorporate a touchpad as a multi-function user input with finger gesturing to control music volume, song selection, pause and play with simple swipe and tap like gestures.

Fig. 55 Example Remote Control with Touchpad¶

Getting Started¶

The guidelines presented this section provide only a basic design overview and general recommendations. To ensure a successful sensor design, it is highly recommended to see application note SLAA944 “Designing a trackpad with MSP430 capacitive touch technology” to better understand how a touchpad sensor works, how to select the optimal design for your application and to be aware of the design limitations.

Topics¶

The section of the CapTIvate design guide covers the following Touchpad topics:

-

Standard

Basic

-

Shapes

Electrode Pitch

Electrode Spacing

How to create sensor patterns

-

PCB Layout and Routing

FR4

FPC

Overlay

Terminology¶

RX or TX electrode = Row or column of diamonds connected to MCU’s CapTIvate IO pins

CAPT IO = Capacitive touch pin

Measurement node = Intersection between RX and TX electrode

Sensor configuration = RX/TX electrode pairs (ex. 4x4 configuration has 4 RX and 4 TX connections)

FR4 = Glass-reinforced epoxy laminate material for PCB substrate

FPC = Flexible PCB

ITO = Indium tin oxide is a transparent thin film conductor

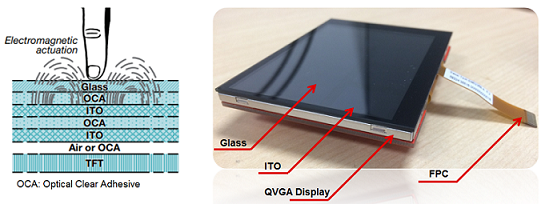

CapTIvate Touchpad Technology Overview¶

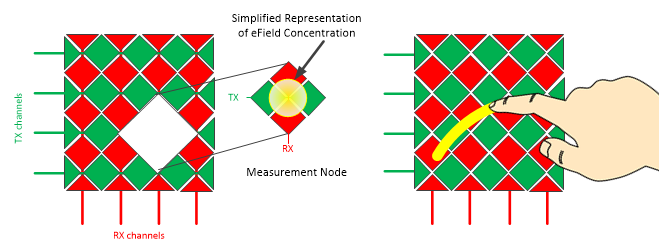

CapTIvate Touchpads are mutual capacitive 2D sensors created by the intersection of rows and columns of diamond shaped patterns referred to as RX and TX electrodes. The diamond pattern provides optimal coupling between the RX and TX electrode and is typically made of copper, as on FR4 rigid and Flex PCBs, or ITO for glass substrates. In the illustration below, the intersection of the 4 RX electrodes and 4 TX electrodes create 16 measurement nodes. When a finger touches the surface, the processing algorithm determines the position of the finger based on the relative change in capacitance at each measurement node. Programmable parameters related to how long the finger touches, the number of touches and touch positions are used by the gesture processing algorithm after each measurement to determine if a Tap, Double-Tap, TapHold, or Swipe (up,down,left,right) has occurred. The XY position and gesture data is available to be read by a host MCU.

Fig. 56 Touchpad Electrodes¶

Touchpad Designs¶

Touchpads can be designed in a variety of sizes, shapes and with lesser or greater XY precision. Applications requiring a greater precision use many RX and TX electrodes to improve the resolution of the measurements, whereas simple gesturing applications don’t need the resolution and can work with fewer RX and TX electrodes. What does your application need? Before starting a touchpad design, let’s briefly look at the two types of touchpad designs and the MSP430 MCUs that support them.

In this document touchpads are referred to as standard or basic. A standard touchpad design solution is expected to provide the performance and features to meet both precision XY finger tracking, as well as gesturing requirements, whereas a basic touchpad design provides a cost sensitive solution for simple gesture applications. The differences are summarized below.

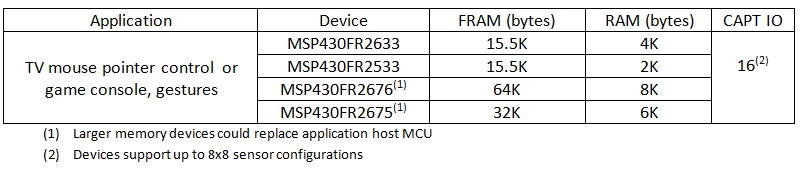

A Standard Touchpad¶

CapTIvate Touchpad designs offer best in class XY position resolution and precision, with gesturing.

These are applications requiring precision tracking performance, such as game or VR applications

Require MSP430 CapTIvate MCUs with more CAPT IO (channels) and larger memory configurations

Fig. 57 Standard Touchpad MCUs¶

A Basic Touchpad¶

A basic CapTIvate Touchpad is a lower cost solution for applications used primarily for gesturing only.

Hand-held remote control or wearable devices

Lower XY precision

Can be implemented on MSP430 CapTIvate MCUs with smaller pin-count and lower memory options

Supports smaller touch areas with 2x2, 3x3 and 4x4 configurations (up to 16 measurement points)

Fig. 58 Basic Touchpad MCUs¶

Sensor Design¶

Shapes

Electrode Pitch

Electrode Spacing

How to Generate Sensor Pattern

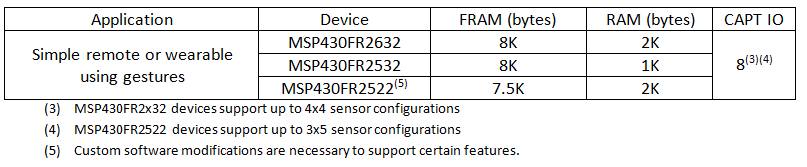

Shapes¶

Generally defined by the product requirements, touchpads are commonly square (rectangular) or round. Custom shapes are possible by using the .dxf output of the desired shape rendered in a CAD program. Refer to section Create the Touchpad PCB Sensor.

Fig. 59 Common Shapes¶

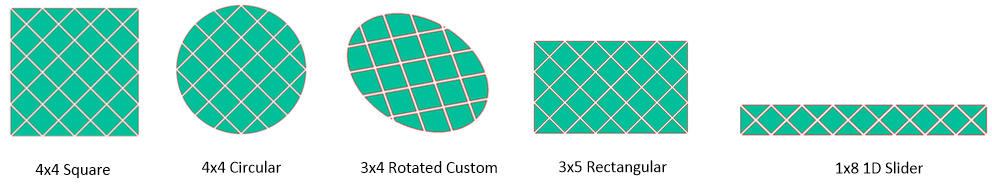

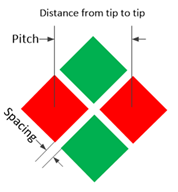

Electrode Pitch¶

A sensor’s pitch is the measured distance from the center of one diamond to the center of a neighboring diamond as shown here. A sensor with smaller pitch will generally have better precision and linearity. A typical electrode pitch is in the range of 3mm to 7mm for a standard touchpad application and 10mm or more for basic touchpad gesturing applications.

Fig. 60 Electrode Pitch and Spacing¶

Electrode Spacing¶

The spacing between the diamond patterns determines the quality of the coupling between an RX and TX diamond. The smaller the spacing, the more tightly coupled the e-field between the diamonds becomes, minimizing crosstalk between channels and improving the sensor’s SNR.

Smaller spacing creates strong coupling with good signal SNR

Larger spacing reduces the signal SNR and degrades cross-talk with neighboring electrodes causing proximity effects

Recommended spacing is 0.1mm (min) to 0.3mm (typical), up to 0.5mm (max) with thicker overlays.

Creating the Touchpad PCB Sensor¶

PCB¶

Layout

Routing

Layer Stack

Ground Pours

PCB Layout and Routing¶

Care must be taken when routing the RX and TX traces from the sensor’s electrodes to the MCU. To avoid unwanted interaction between RX and TX traces always keep the RX and TX traces grouped separately an as far apart from each other as possible. If touchpad signal traces route near a ground trace or ground pour, maintain a gap of 0.5mm or more between the ground pour and electrodes.

Stack Up¶

Touchpads are typically implemented on 2 to 6 layer FR4 and 2 layer FPC. It is also possible to implement a touchpad on ITO substrates, but is highly recommended to work with an ITO vendor that can advise on the layout.

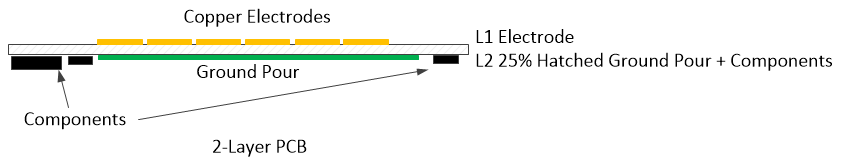

2 Layer Designs¶

L1 Electrode

L2 Ground Pour

On a 2 layer design, the MCU and other components should not placed on the layer directly under the sensor. The area on the lower layer under the touchpad sensor is reserved for the ground pour so do not place components in this area. On 2 layer FR4 designs, use a 25% filled hatched pour and on 2 layer FPC designs, use a 10% filled hatched pour.

Fig. 61 2-Layer Stack up¶

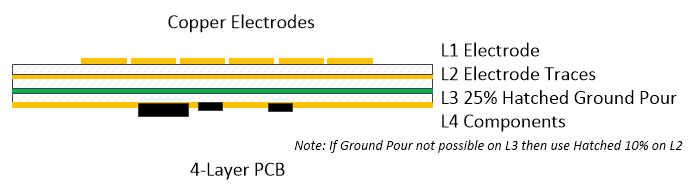

Multi-Layer¶

L1 Electrode

L2 Electrode Traces

L3 Ground Pour

L4 Components

On a multi-layer design, the MCU and other components can be mounted directly under the sensor provided there is a 25% filled hatched ground pour on layer 3 (preferred), or a 10% filled hatched ground pour on L2.

Fig. 62 4-Layer Stack up¶

Ground Pours¶

A ground pour is an important part of the touchpad sensor, as it provides a stable ground reference for the sensor measurements and is needed to shield the touchpad sensor potential noise sources from the lower layers on the PCB. To minimize parasitic capacitances, which can affect the sensor’s sensitivity, on FR4 PCB designs always use a hatched ground pour that is around 10 - 25%, depending on which layer (see comments above). On FPC designs, the layers are much closer together, which increases the parasitic capacitance between the electrodes and ground pour on the opposite layer. This increased parasitic capacitance will reduce the sensor’s sensitivity so it is recommended to use a 10% filled hatched ground. ITO designs typically do not include a hatched ground.

Fig. 63 Example 25% Filled Ground Pour¶

Touchpad Overlay¶

The overlay is a very important part of the capacitive touch sensor design and can impact the overall performance. The recommended overlay thickness ranges from 1 to 3mm. The overlay material must be non-conductive, such as plastic or glass.

Proximity¶

Proximity sensors are electrodes designed to detect a hand or other conductive object at some distance using greater sensitivity compared to buttons, sliders or wheels. For this reason, proximity sensors are recommended to use self capacitive mode and can have one or more electrodes. By having the proximity sensor in your design can reduce the system power consumption and provide the feedback to human interact.

Proximity Design Considerations¶

The sensing range of a proximity sensor is dependent upon several factors:

The size and shape of the proximity sensor

The proximity range increases with the larger sensor size.

The proximity range also affect by the area of the object approaching to the sensor.

The shape of sensor is most limited by end product and it varies from a solid rectangular pad to a piece of wire.

The sensor configuration tuning values

The proximity range increases with higher sensitivity tuning values.

The values include conversion count, conversion gain, and proximity threshold.

The surrounding conductors

The proximity range increases with increasing the separation of the sensor from other conductors, such as ground.

The system surrounding environment

Increasing the sensitivity of the proximity sensor will also enlarge the effects of noise, temperature drifts and humidity drift to the system.

Overall, proximity sensor design involves carefully balancing sensor size, sensor configuration, ground shielding and system stability.

Proximity Ground and Shielding¶

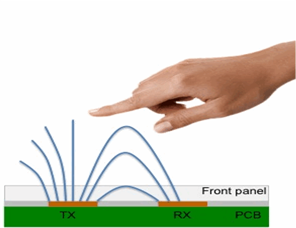

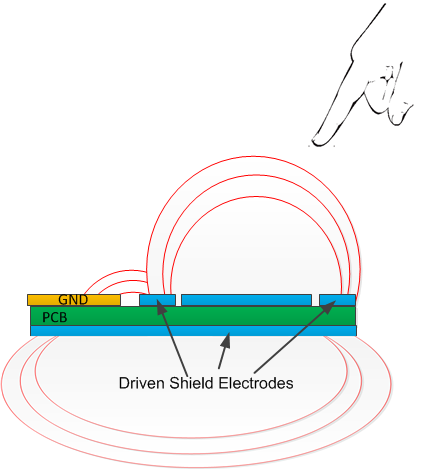

Electric Field Propagation¶

As with any self-capacitive sensor, an isotropic electric field is generated from the electrode and is projected in all directions. The field lines will flow from the electrode to any nearby ground potential and can include a nearby hand or earth ground. This means a hand can approach the sensor from any angle and interact with the E-field. If proximity detection is undesirable from the back or the side of the device, this could easily be prevented by manipulating the direction of the E-field’s projection using different shield implementation methods.

Fig. 64 PCB with Minimal Parasitic Capacitances¶

Proximity Sensor with No Shield¶

A proximity sensor without any shielding mechanism can be fully functional, but only applicable if detection from any angle can be permitted. In comparison with other implementation methods, having no shield provides high sensitivity, yielding a long range of sensing distance in 360 degrees. Unfortunately, it is almost impossible to avoid having some ground structures on a PCB or in the product. The presence of these ground structures leads to increase parasitic loading on the sensor, which reduces the percentage change in capacitance when a user approaches the sensor. This leads to a reduction in the sensor’s sensitivity and, ultimately, the detection distance. The proximity electrode on the CAPTIVATE-BSWP board is an example of a sensor without significant shielding.

Fig. 65 PCB with Typical Parasitic Capacitances¶

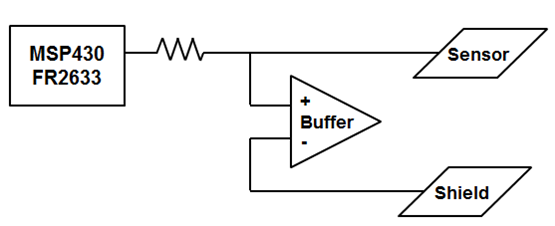

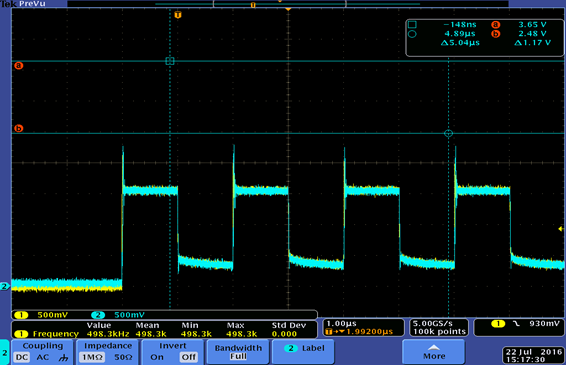

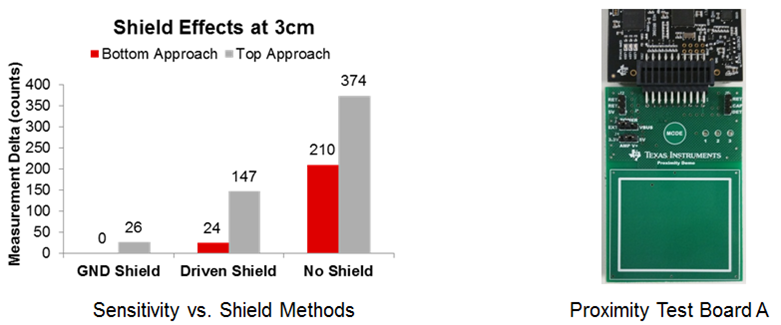

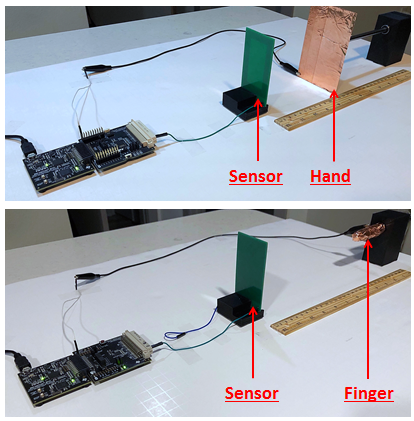

Proximity Sensor with Ground Shield¶