Motor Control Software Development Kit¶

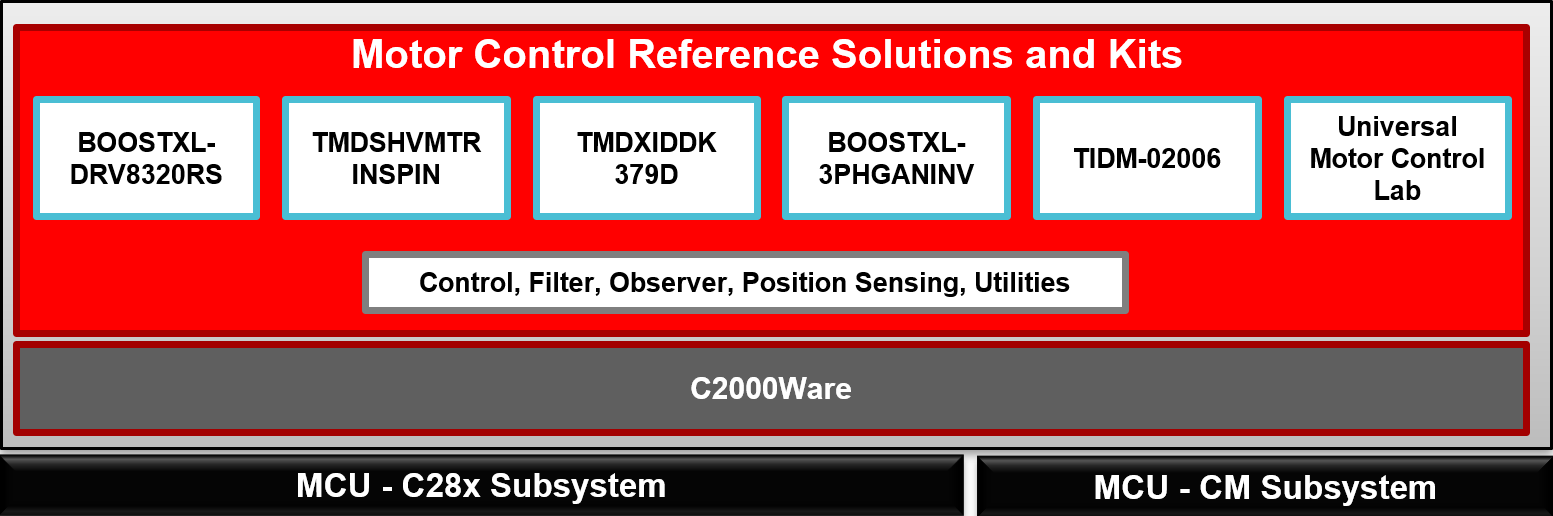

The MotorControl SDK (MC SDK) is a cohesive set of software infrastructure, tools, and documentation designed to minimize C2000 real-time controller based motor control system development time targeted for various three-phase motor control applications. The software includes firmware that runs on C2000 motor control evaluation modules (EVMs) and TI designs (TIDs) which are targeted for industrial drives, robotics, appliances, and automotive applications. MotorControl SDK provides all the needed resources at every stage of development and evaluation for high performance motor control applications.

MC SDK has the latest sensored servo, sensorless InstaSPIN-FOC and sliding mode observer solutions, real-time connectivity examples, incremental and absolute encoders, and the Fast Current Loop (FCL) optimized software library.

The MC SDK is built on top of C2000Ware and is available for download from C2000WARE-MOTORCONTROL-SDK. The SDK is also available online via the TI Resource Explorer for C2000 MC SDK. For a list of supported devices, kits, and reference designs, see the latest MC SDK release notes.

Fig. 6 Motor Control SDK¶

Features¶

Complete software repository for C2000 MCU Motor Control Applications

Sensorless solutions

Sensorless Torque or Velocity

Trapezoidal or Field Oriented Control

Enhanced sliding mode observer for open solution, best for high-speed applications

InstaSPIN-FOC

FAST™ software observer for premium rotor Flux, Angle, Speed, and Torque estimationsMotor Parameter Identification

Motor Parameter Identification

Observer and torque control loop automatic tuning

Premium performance for low-speed and highly dynamic applications

Reference designs may include the following examples

Send commands through CAN interface, potentiometer analog input, and frequency input

System protection

Flying start

Field Weakening

Stall detection and recovery

Start-up failure detection and recovery

Lost phase detection/protection

Motor stop with brake

Vibration and acoustic compensation

Initial Position Detection

Maximum Torque Per Amp (MTPA) for IPM motors

Sensored FOC solutions

Sensored Velocity or Position Field Oriented Control

Position feedback: Resolver, Incremental and Absolute Encoders

Current sense techniques: Low-side shunt, in-line current sampling, and sigma-delta filter demodulation

Fast Current Loop (FCL): Optimized software library that takes full advantage of hardware resources to accelerate the sampling, processing, and actuation of the system to achieve the highest control bandwidth for a given PWM frequency in servo control applications.

Real-time connectivity examples (EtherCAT, CAN, CAN-FD, FSI)

Decentralized / Distributed architecture examples

Use of Configurable Logic Block for absolute encoders, pulse train input/output, QEP decode, and dead-band compensation

Supported Solutions¶

Table 3 summarizes key kits supported in the Motor Control SDK. Please check the latest MC SDK release notes for an up to date list of solutions.

EVM / TI Design |

C2000™ SoC |

Description |

|---|---|---|

F2838x, F28004x, F28002x |

Distributed multi-axis servo drive over fast serial interface (FSI) reference design |

|

F2837x, F28004x |

Dual-axis motor drive using fast current loop (FCL) and SFRA on a single MCU reference design |

|

F280013x, F28002x, F28003x |

Dual motor control with digital interleaved PFC for HVAC reference design |

|

F28003x |

High-voltage EV/HEV HVAC eCompressor motor control reference design |

|

F280013x, F28002x, F28003x |

Single project example for different Sensorless (FAST, eSMO, InstaSPIN-BLDC), Sensored (Incremental Encoder, Hall), and control techniques (FOC, Trapezoidal) |

|

F28004x |

InstaSPIN-FOC labs for F28004x FAST ROM |

|

F2838x, F2837x, F28004x, F28002x |

Quick response control of PMSM using Fast Current Loop on the DesignDRIVE Development Kit |

|

Position Encoders |

F2838x, F2837x, F28004x, F28002x, F28003x |

Implemented using Configuration Logic Block and / or other peripherals of C2000 devices T-format Master, PTO – QEP, PTO – PulseGen, PTO – QEP Div, PTO – Abs2QEP |

Servo drive with CAN |

F28002x, F28003x, F28004x |

Sensored FOC motor drive using QEP with integrated CAN communication to control the motor |