10.1. Target¶

10.1.1. Run IPC Examples on AM572x¶

10.1.1.1. DRA7xx/AM572xx IPC Examples¶

IPC Hello Example:

ex01_hello

The following examples demonstrate some of the rudimentary IPC capabilities. They are mostly two processors examples. These examples may be built for any two processors on your device, but only for two at a time. An IPC Ping example using three processors is also presented at the end.

Hello example uses the reader/writer design pattern. One processor will be the reader and the other will be the writer. The reader creates a message queue and waits on it for messages. The writer opens the reader’s message queue and sends messages to it. The writer allocates the message from a shared message pool and the reader returns the message to the pool. Thus, messages are sent in only one direction. Default settings of the Hello world example configures DSP1 as the writer and DSP2 as the reader.

Note

if Windows 7 machine is used for building these examples, GnuWin32 make utility needs to be installed to run make which can be downloaded from this link https://gnuwin32.sourceforge.net/packages/make.htm

Set GnuWin32\bin folder on file path and add a system variable XDCTOOLS_JAVA_HOME to point to “c:\ti\ccsv6\eclipse\jre“

set PATH=<YOUR_PROCEEDING_PATH>\GnuWin32\bin;%PATH%

set XDCTOOLS_JAVA_HOME=c:\ti\ccsv6\eclipse\jre

1. Change to the example folder by entering: cd ~/ti/ipc_nn_nn_nn_nn/examples/DRA7xx_bios_elf/ex01_hello

2. Open readme.txt file and follow build instructions step-by-step. If build this example on Ubuntu PC, make sure there is no spaces between variable name and its value.

DEPOT (your depository folder ex: DEPOT=/Your_Ubuntu_home_folder/ti)

BIOS_INSTALL_DIR=$(DEPOT)/bios_n_nn_nn_nn

IPC_INSTALL_DIR=$(DEPOT)/ipc_n_nn_nn_nn

XDC_INSTALL_DIR=$(DEPOT)/xdctools_n_nn_nn_nn

gnu.targets.arm.A15F=$(DEPOT)/ccsv6/tools/compiler/gcc-arm-none-eabi-4_8-2014q3

ti.targets.elf.C66=$(DEPOT)/ccsv6/tools/compiler/c6000_7.4.14

ti.targets.arm.elf.M4=$(DEPOT)/ccsv6/tools/compiler/arm_5.2.4

ti.targets.arp32.elf.ARP32_far=$(DEPOT)/ccsv6/tools/compiler/arm_5.2.4

See the following example, and ensure you are using the latest version

of folder names present in ~/ti folder:

DEPOT=/home/Your_Ubuntu_home_folder/ti

# Use the following environment assignment (Note you must use 32 bit Java even in Ubuntu 14.04 64 bit OS environment)

export XDCTOOLS_JAVA_HOME=/home/Your_Ubuntu_home_folder/ti/ccsv6/eclipse/jre

#### BIOS-side dependencies ####

BIOS_INSTALL_DIR=$(DEPOT)/bios_6_41_04_54

IPC_INSTALL_DIR=$(DEPOT)/ipc_3_36_01_11

XDC_INSTALL_DIR=$(DEPOT)/xdctools_3_31_02_38

#### BIOS-side toolchains ####

gnu.targets.arm.A15F=$(DEPOT)/ccsv6/tools/compiler/gcc-arm-none-eabi-4_8-2014q3

ti.targets.elf.C66=$(DEPOT)/ti-cgt-c6000_8.0.3

ti.targets.arm.elf.M4=$(DEPOT)/ccsv6/tools/compiler/ti-cgt-arm_5.2.4

ti.targets.arp32.elf.ARP32_far=$(DEPOT)/ccsv6/tools/compiler/ti-cgt-arm_5.2.4

- Run make command in current folder to build DSP1 and DSP2 hello examples. Output files are created under debug sub folders.

- ex01_hello\dsp1\bin\debug

- ex01_hello\dsp2\bin\debug

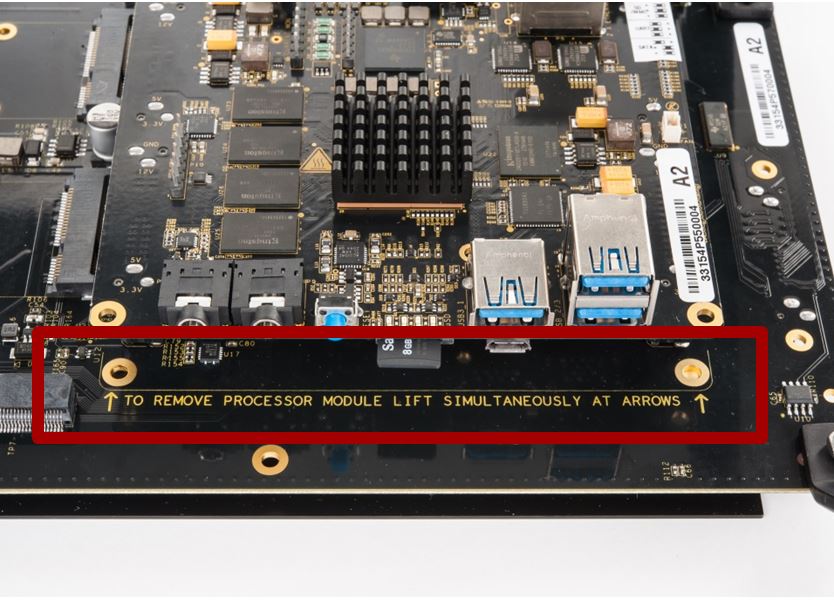

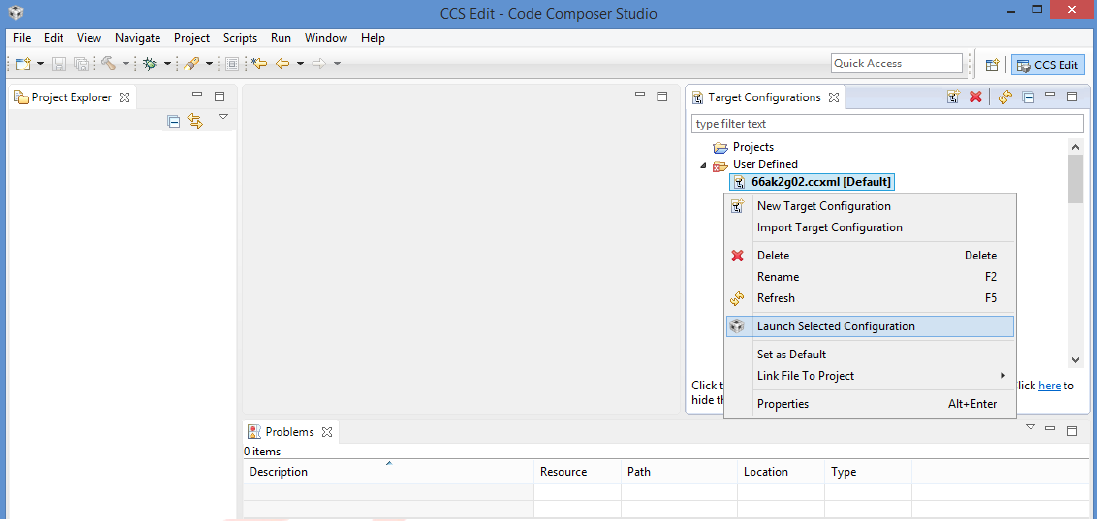

- Launch target configurations.

- Right click CortexA15_0 and connect target.

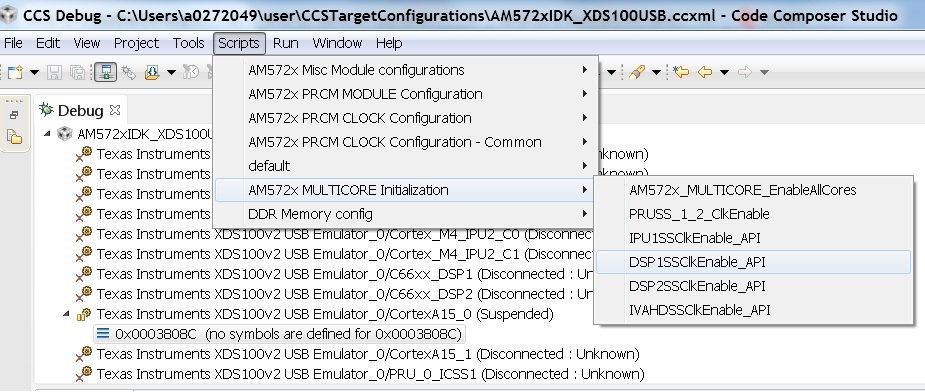

- On CCS –> Scripts –> AM572 Multicore Initialization –> Run AM572x Multicore EnableAllCore

- Initialize DDR configuration. On CCS –> Scripts –> DDR configurations –> AM572_DDR3_532MHz_config

- Load DSP1 Hello Example hello_dsp1.xe66 (writer)file on DSP1.

- Load DSP2 Hello Example hello_dsp2.xe66 (reader) file on DSP2.

- Run both DSP1 and DSP2.

- On CCS –> Tools –> RTOS Object view (ROV).

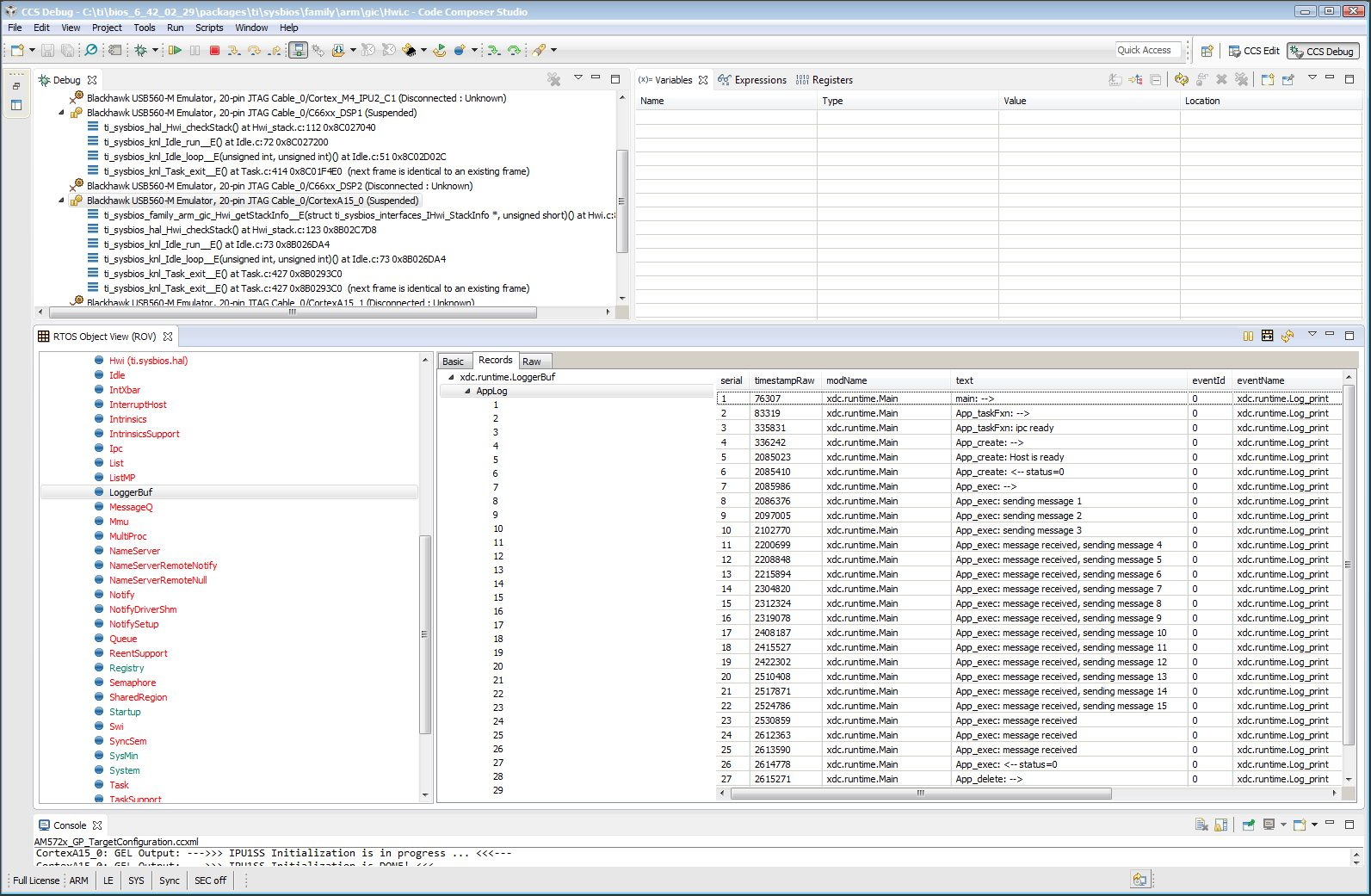

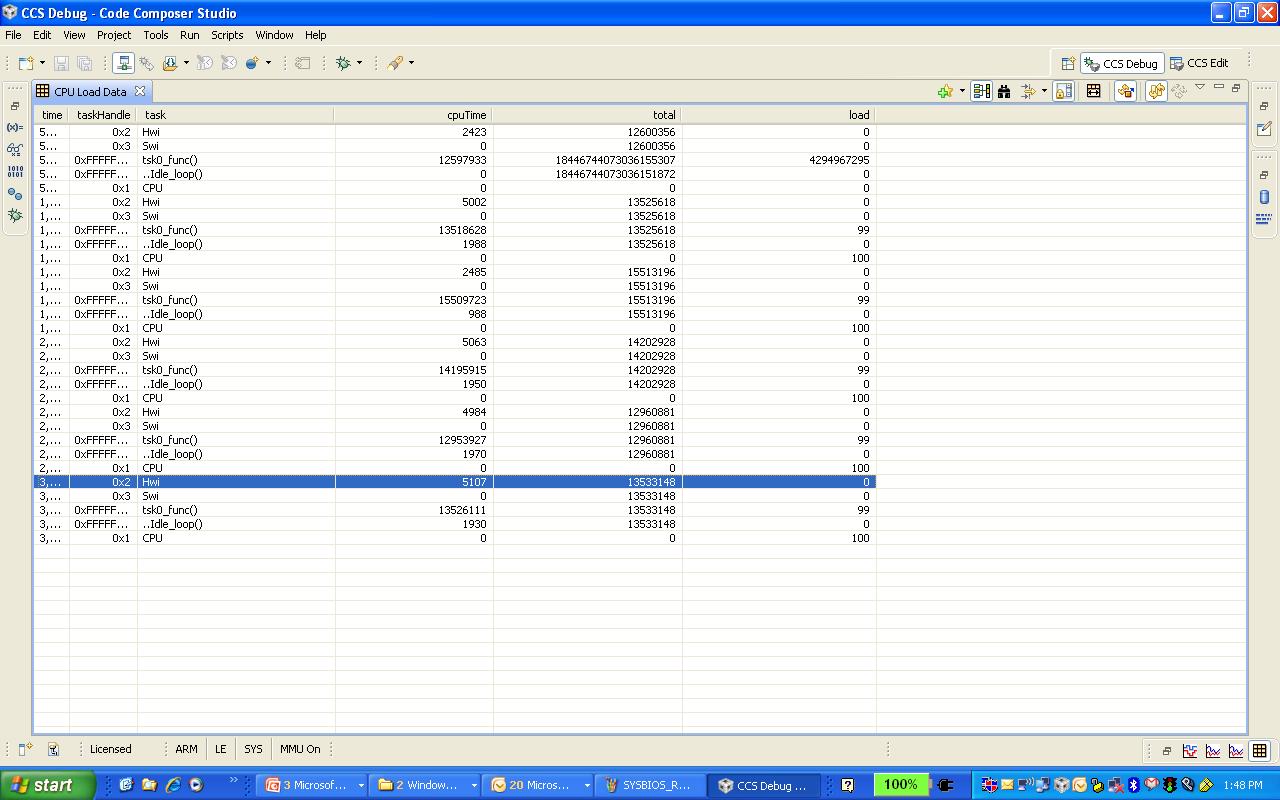

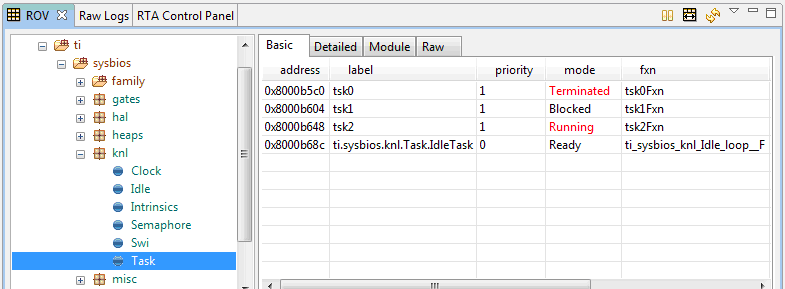

- Suspend (halt) DSP1 to view test messages on ROV Viewable Modules –>LoggerBuf Refer below image of ROV log messages.

- Suspend (halt) DSP2 and click on ROV icon to view log messages.

IPC Message Queue Example:

ex02_messageq

Message queue example sends round-trip message from client to server and back. MessageQ example uses client/server pattern. It is a two processors example: the HOST and DSP processors. Either DSP1 or DSP2 can be built for testing.

The DSP processor is configured as server. It creates a named message queue. The server does not open any queues because it extracts the return address from the message header. The server returns all messages to the sender. It does not access the message pool.

The HOST processor is configured as client application. The client creates an anonymous message queue. The client also creates and manages the message pool. The client’s return address is set in the message header for each message before sending it to the server.

- Change to messageQ folder example by enter:

cd ~/ti/ipc_nn_nn_nn_nn/examples/DRA7xx_bios_elf/ex02_messageQ

2. Open readme.txt file and follow build instructions step-by-step. Make sure there is no spaces between variable name and its value. See Hello World example environment varaible settings for reference.

- Run make command in current folder to build DSP1 and HOST hello examples. Output files are created under debug sub folders

- ex02_messageq\host\bin\debug : HOST A15 binary

- ex02_messageq\dsp1\bin\debug : C66x binary

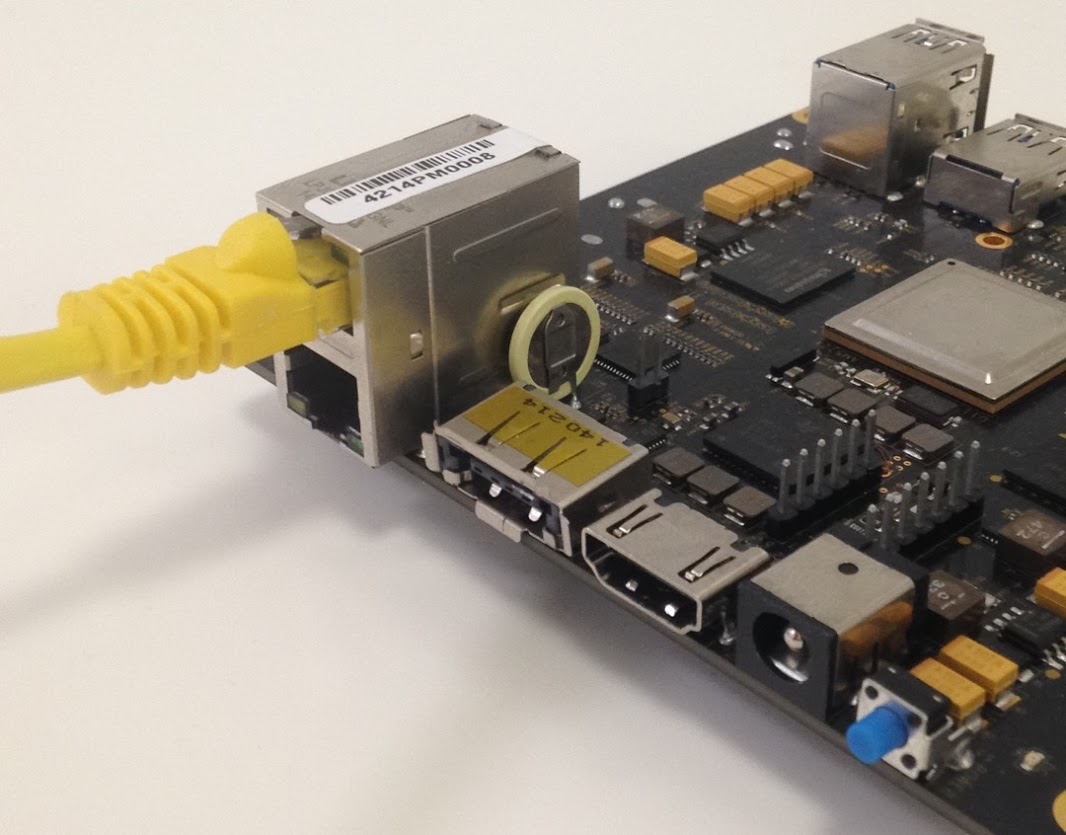

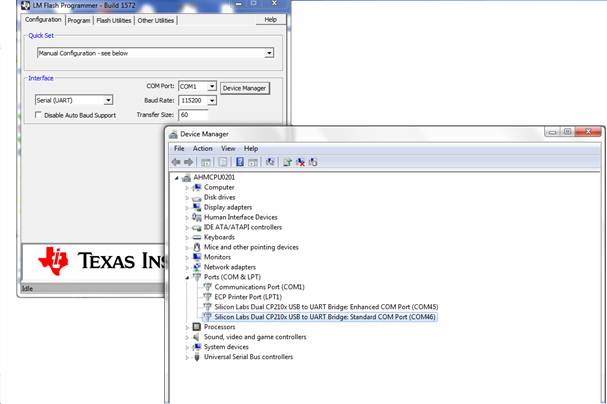

- Launch target configurations. Note that BH560USB_M is emulator is used to connect to AM572X EVM.

- Right click CortexA15_0 and connect target.

- On CCS –> Scripts –> AM572 Multicore Initialization –> Run AM572x Multicore EnableAllCore

- Initialize DDR configuration. On CCS –> Scripts –> DDR configurations –> AM572_DDR3_532MHz_config

- Load DSP1 messageQ Example out file(server_dsp1.xe66) onto DSP1.

- Load HOST messageQ Example out file(app_host.xa15fg) onto ARM CortexA15_0.

- Run both DSP1 and HOST.

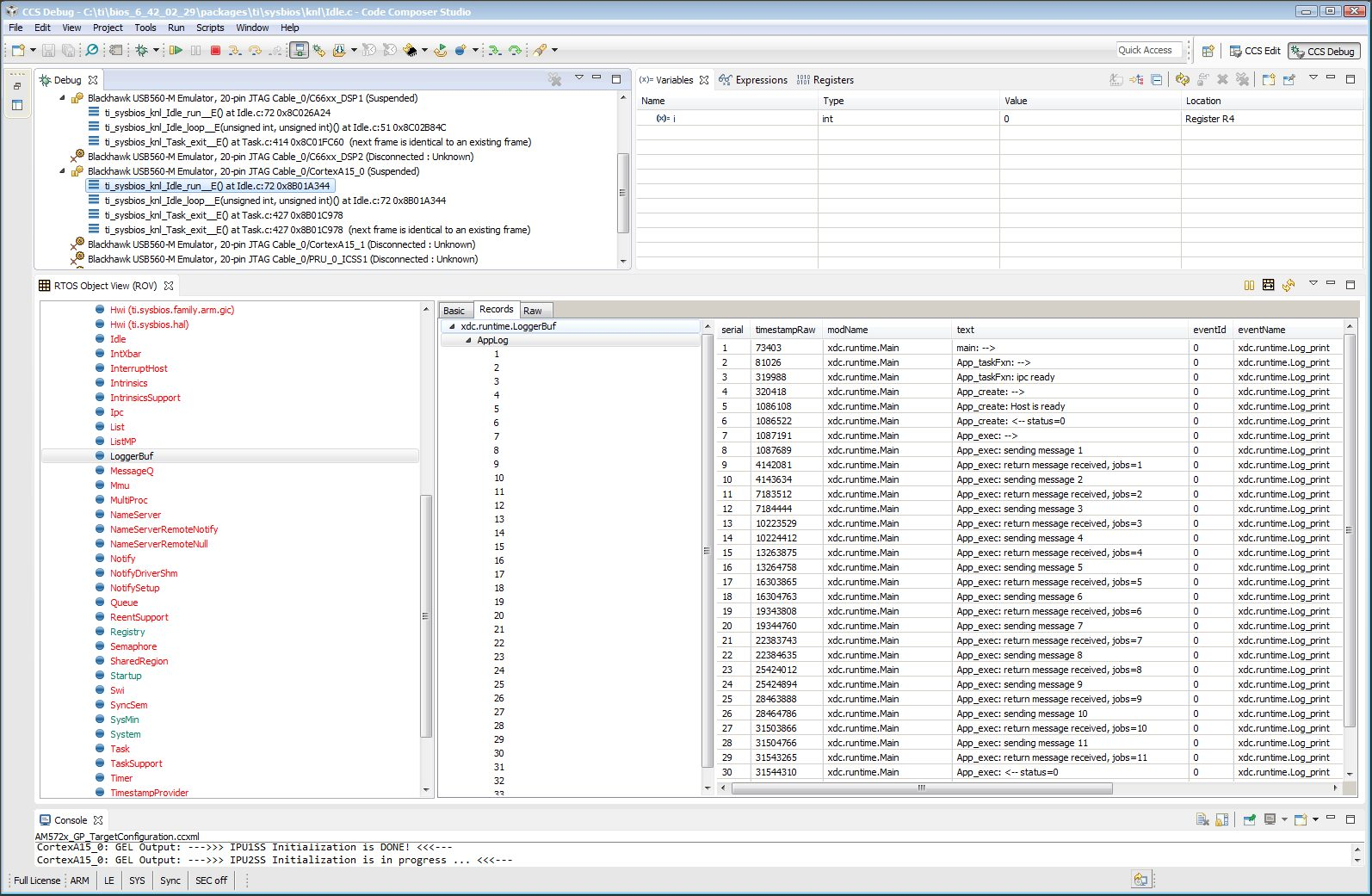

- On CCS –> Tools –> RTOS Object view (ROV).

- Suspend (halt) ARM Cortex_A15 to view test messages on ROV Viewable Modules –>LoggerBuf Refer the following ROV message queue screenshot

- Suspend (halt) DSP1 and click on ROV icon to view log messages.

IPC Notify Peer Example:

ex13_notifypeer

Notify peer example only uses notify to communicate to a peer processor. This is an example of IPC Scalability. It uses the client/server design pattern. Initially, the example builds only for two processors: HOST and DSP1. The client runs on HOST and the server runs on DSP1.

The client (HOST) creates an anonymous message queue. The client also creates and manages its own message pool. And it opens the server message queue using its name. The client initiates the data flow by allocating a message from the pool, placing its return address in the message header and sending the message to the server. It then waits for the message to be returned. When it receives the return message, the message is returned to the pool. The client repeats this in a loop.

The server (DSP1) creates a named message queue, then waits on it for messages. When a message arrives, the server performs the requested work. When the work is done, the server extracts the return address from the message header and sends the message back to the client. The server never opens any message queues and does not access the message pool.

Since DSP1 will need to wait on both the message queue and the notify queue, we introduce events. The SYS/BIOS event object can be used to wait on multiple input sources.

- Change to notify_peer folder example by enter: cd ~/ti/ipc_nn_nn_nn_nn/examples/DRA7xx_bios_elf/ex13_notifypeer

- Open readme.txt file and follow build instructions step-by-step. Make sure there is no spaces between variable name and its value.

- Run make command in current folder to build DSP1 and HOST notifypeer examples. Output files are created under debug subfolder.

- Launch target configurations. Note that BH560USB_M is emulator is used to connect to AM572X EVM.

- Right click CortexA15_0 and connect target.

- On CCS –> Scripts –> AM572 Multicore Initialization –> Run AM572x Multicore EnableAllCore

- Initialize DDR configuration. On CCS –> Scripts –> DDR configurations –> AM572_DDR3_532MHz_config

- Load DSP1 notifypeer Example out file on DSP1.

- Load HOST notifypeer Example out file on ARM CortexA15_0.

- Run both DSP1 and CortexA15_0.

- On CCS –> Tools –> RTOS Object view (ROV).

- Suspend (halt) ARM CortexA15_0 to view test messages on ROV Viewable Modules –>LoggerBuf. Refer the following image of ROV log messages

- Suspend (halt) DSP2 and click on ROV icon to view log messages.

IPC Ping Example:

ex11_ping

ping example sends a message between all cores in the system. This example is used to exercise every communication path between all processors in the system (including local delivery on the current processor). Ping example is also organized in a suitable manner to develop an application with different compute units on each processor.

Each executable will create two tasks: 1) the server task, and 2) the application task. The server task creates a message queue and then waits on that queue for incoming messages. When a message is received, the server task simply sends it back to the original sender.

The application task creates its own message queue and then opens every server message queue in the system (including the server queue on the local processor). The task sends a message to a server and waits for the message to be returned. This is repeated for each server in the system (including the local server).

Note

Note that presently EVE is not yet supported and therefore, DSP1/DSP2/HOST are built for testing.

1. Change to ping folder example by enter: cd ~/ti/ipc_nn_nn_nn_nn/examples/DRA7xx_bios_elf/ex11_ping

2. Open readme.txt file and follow build instructions step-by-step. Make sure there is no space between variable name and its value.

- Open makefile and remove EVE and IPU from PROC build list.

- Run make command in current folder to build DSP1, DSP2 and HOST ping examples. Output files are created under debug subfolder.

- Launch target configurations. Note that BH560USB_M is emulator is used to connect to AM572X EVM.

- Right click CortexA15_0 and connect target.

- On CCS –> Scripts –> AM572 Multicore Initialization –> Run AM572x Multicore EnableAllCore

- Initialize DDR configuration. On CCS –> Scripts –> DDR configurations –> AM572_DDR3_532MHz_config

- Load DSP1 Ping Example out file on DSP1.

- Load DSP2 Ping Example out file on DSP2.

- Load HOST ping Example onto ARM CortexA15_0

- Run DSP1, DSP2, and HOST images.

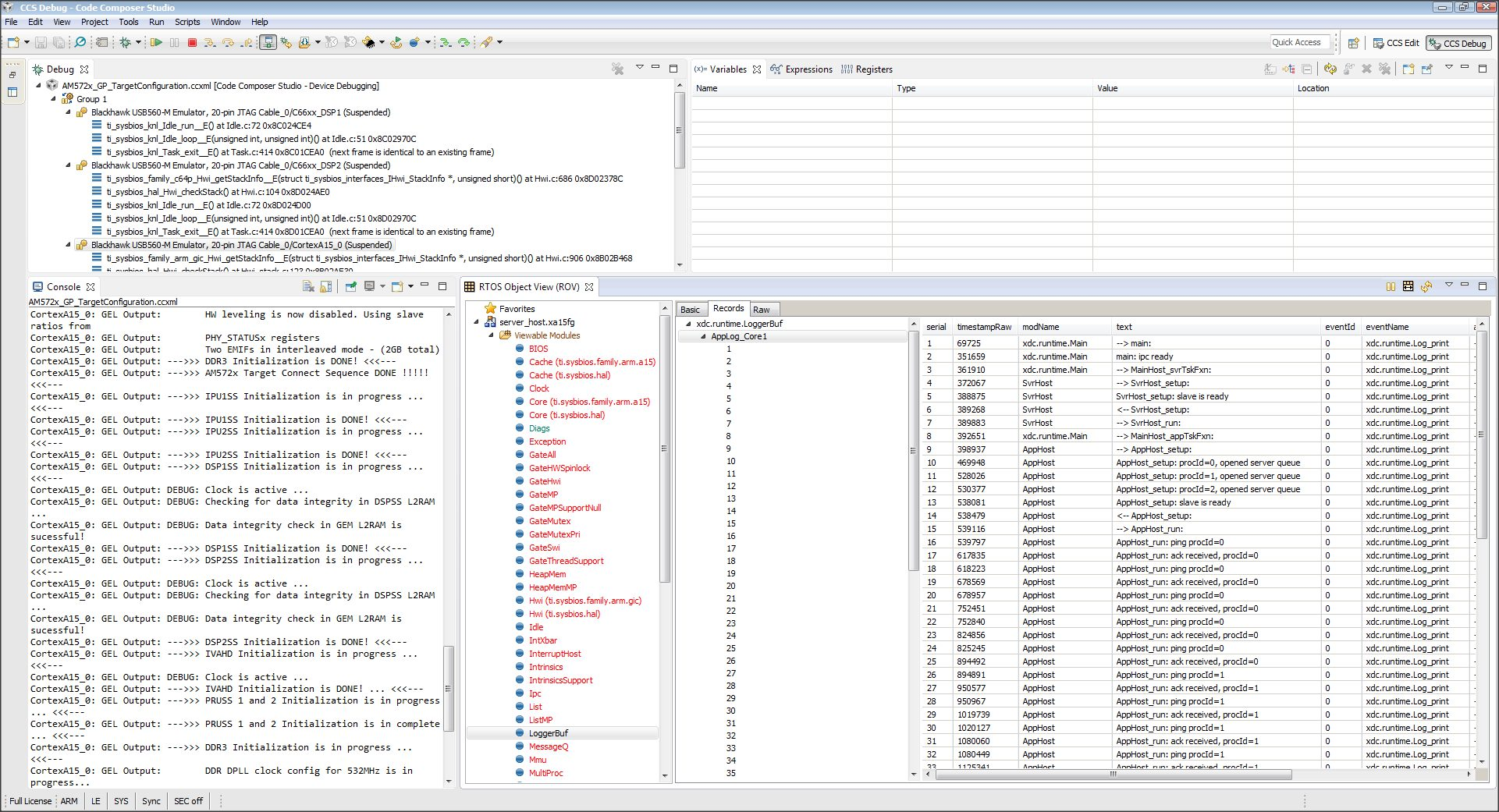

- On CCS –> Tools –> RTOS Object view (ROV).

- Halt DSP1 to view test messages on ROV Viewable Modules –>LoggerBuf Refer below image of ROV log messages

- Suspend (halt) DSP2 and click on ROV icon to view log messages.

- Suspend (halt) ARM CortexA15_0 and click on ROV icon to view log messages.

Expanding IPC Ping Example:

To demonstrate the flexibility of IPC architecture, you may include additional cores to the above example by modifying the make file. For example, you may add IPU1 in the list of processor in the make file as: DSP1, DSP2, IPU1, HOST. After a clean build, the appropriate configuration and output executable files will be generated that allow passing messages between DSP1, DSP2, IPU1 and Host. Procedures are the same as described in the previous example with the exception of additional steps to load the IPU1 core with the corresponding executable and running it in conjunction with DSP1, DSP2 and HOST.

Note

During build process using IPU1, you may encounter a message indicating rtsv7M4_T_le_eabi.lib library is missing. This is a know issue and is being tracked by SDCOM00118417 IR. However, you may create this missing library by going to the compiler installation’s lib directory and execute the following command to regenerate all required libraries:

./mklib --all

The following example depicts a typical host communications protocol with other IPC apps (dsp1, dsp2, ipu1) Note that the following HOST communications list has been rearranged to further clarify the type of communications between various cores. Typically these messages arrive at different intervals depending on each core processes execution time.

1 xdc.runtime.Main --> main:

2 xdc.runtime.Main main: ipc ready

3 xdc.runtime.Main MainHost_svrTskFxn:

4 SvrHost --> SvrHost_setup:

5 SvrHost SvrHost_setup: slave is ready

6 SvrHost <-- SvrHost_setup:

7 SvrHost --> SvrHost_run:

8 xdc.runtime.Main --> MainHost_appTskFxn:

9 AppHost --> AppHost_setup:

10 AppHost AppHost_setup: procId=0 opened server queue

11 AppHost AppHost_setup: procId=1 opened server queue

12 AppHost AppHost_setup: procId=2 opened server queue

28 AppHost AppHost_setup: procId=3 opened server queue

32 AppHost AppHost_run: ping procId=0

34 AppHost AppHost_run: ping procId=0

36 AppHost AppHost_run: ping procId=0

38 AppHost AppHost_run: ping procId=0

40 AppHost AppHost_run: ping procId=0

33 AppHost AppHost_run: ack received procId=0

35 AppHost AppHost_run: ack received procId=0

37 AppHost AppHost_run: ack received procId=0

39 AppHost AppHost_run: ack received procId=0

41 AppHost AppHost_run: ack received procId=0

13 SvrHost SvrHost_run: message received procId=0

14 SvrHost SvrHost_run: message received procId=0

15 SvrHost SvrHost_run: message received procId=0

16 SvrHost SvrHost_run: message received procId=0

17 SvrHost SvrHost_run: message received procId=0

42 AppHost AppHost_run: ping procId=1

44 AppHost AppHost_run: ping procId=1

46 AppHost AppHost_run: ping procId=1

48 AppHost AppHost_run: ping procId=1

50 AppHost AppHost_run: ping procId=1

43 AppHost AppHost_run: ack received procId=1

45 AppHost AppHost_run: ack received procId=1

47 AppHost AppHost_run: ack received procId=1

49 AppHost AppHost_run: ack received procId=1

51 AppHost AppHost_run: ack received procId=1

18 SvrHost SvrHost_run: message received procId=1

19 SvrHost SvrHost_run: message received procId=1

20 SvrHost SvrHost_run: message received procId=1

21 SvrHost SvrHost_run: message received procId=1

22 SvrHost SvrHost_run: message received procId=1

52 AppHost AppHost_run: ping procId=2

55 AppHost AppHost_run: ping procId=2

58 AppHost AppHost_run: ping procId=2

61 AppHost AppHost_run: ping procId=2

64 AppHost AppHost_run: ping procId=2

54 AppHost AppHost_run: ack received procId=2

57 AppHost AppHost_run: ack received procId=2

60 AppHost AppHost_run: ack received procId=2

63 AppHost AppHost_run: ack received procId=2

66 AppHost AppHost_run: ack received procId=2

53 SvrHost SvrHost_run: message received procId=2

56 SvrHost SvrHost_run: message received procId=2

59 SvrHost SvrHost_run: message received procId=2

62 SvrHost SvrHost_run: message received procId=2

65 SvrHost SvrHost_run: message received procId=2

67 AppHost AppHost_run: ping procId=3

69 AppHost AppHost_run: ping procId=3

71 AppHost AppHost_run: ping procId=3

73 AppHost AppHost_run: ping procId=3

75 AppHost AppHost_run: ping procId=3

68 AppHost AppHost_run: ack received procId=3

70 AppHost AppHost_run: ack received procId=3

72 AppHost AppHost_run: ack received procId=3

74 AppHost AppHost_run: ack received procId=3

76 AppHost AppHost_run: ack received procId=3

23 SvrHost SvrHost_run: message received procId=3

24 SvrHost SvrHost_run: message received procId=3

25 SvrHost SvrHost_run: message received procId=3

26 SvrHost SvrHost_run: message received procId=3

27 SvrHost SvrHost_run: message received procId=3

29 AppHost AppHost_setup: slave is ready

30 AppHost <-- AppHost_setup:

31 AppHost --> AppHost_run:

77 AppHost <-- AppHost_run: 0

78 AppHost --> AppHost_destroy:

79 AppHost <-- AppHost_destroy: status=0

80 xdc.runtime.Main <-- MainHost_appTskFxn: 0

81 xdc.runtime.Main MainHost_done:

10.1.2. Run IPC Examples on AM65XX¶

10.1.2.1. AM65xx IPC Examples¶

In the processor SDK release ipc examples can be built from the Processor SDK top level makefile.

See link for building IPC examples

ipc-rtos-examples

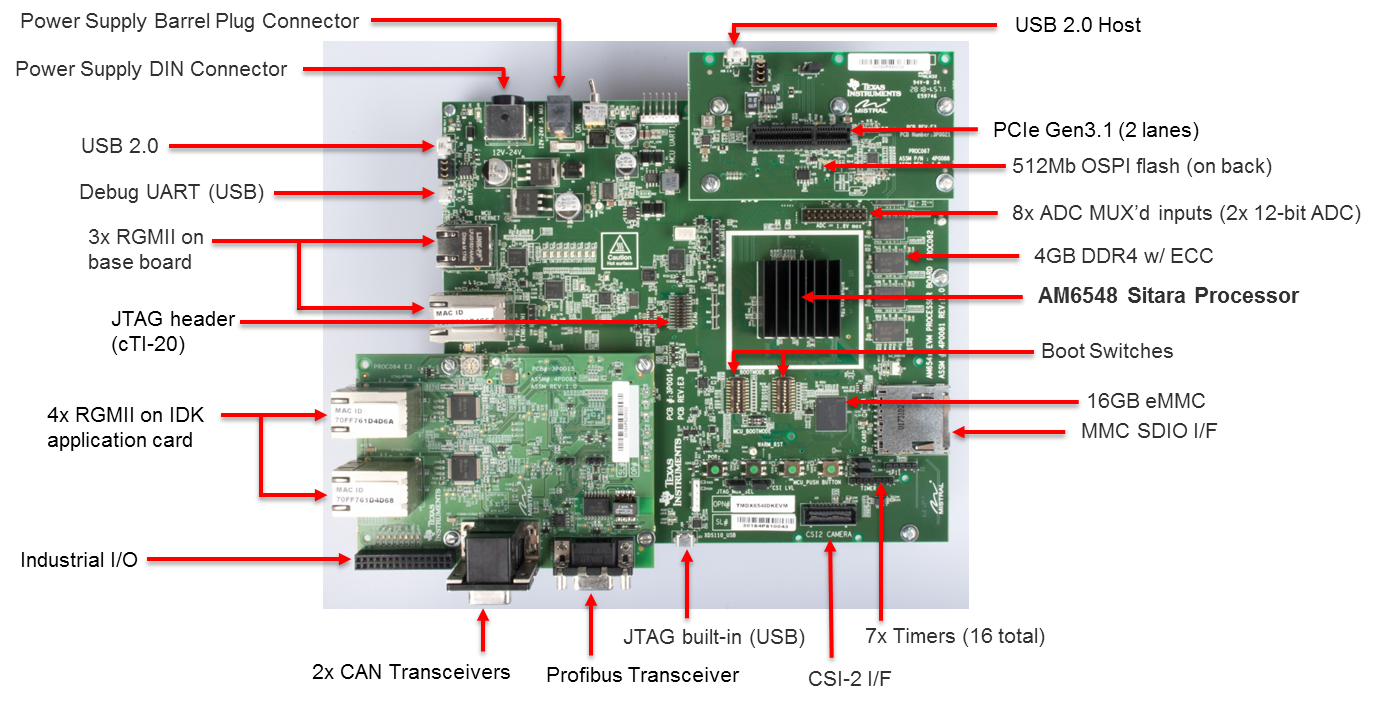

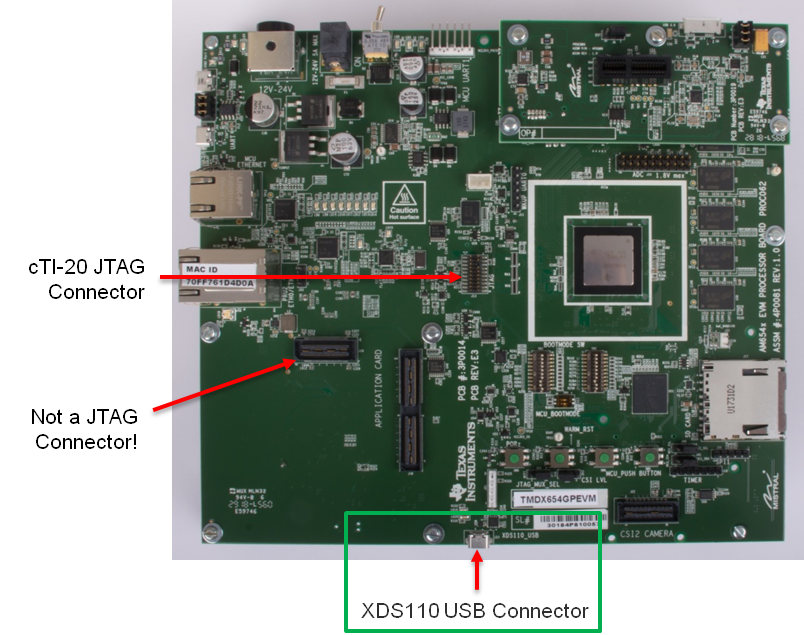

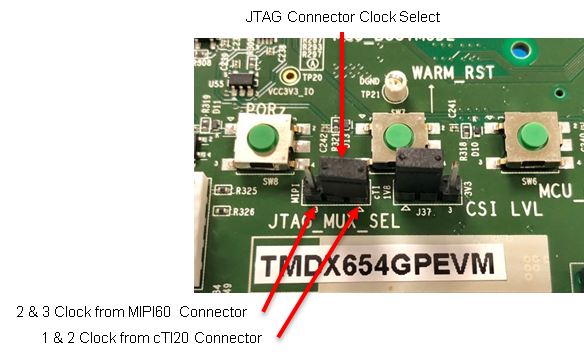

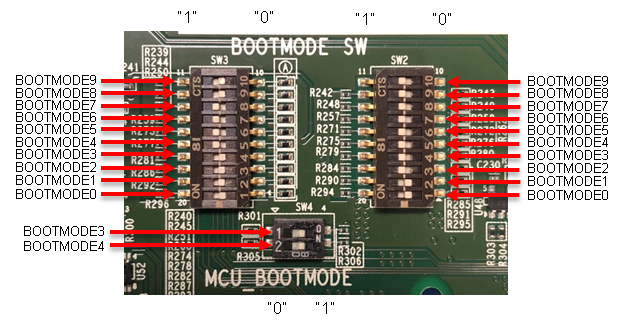

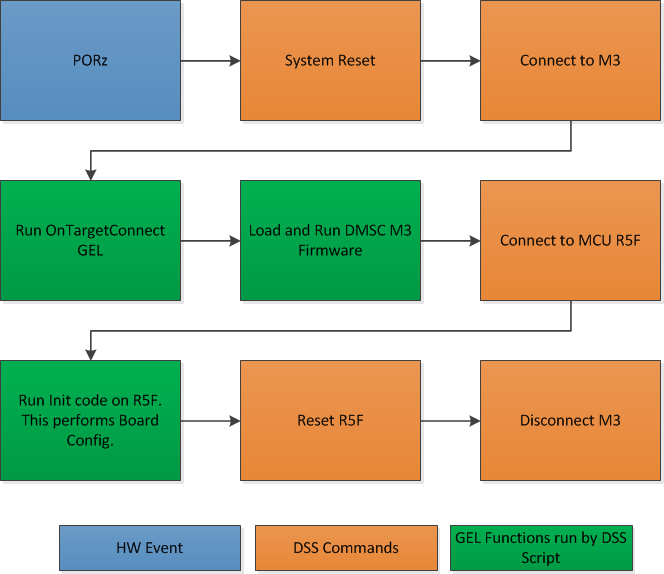

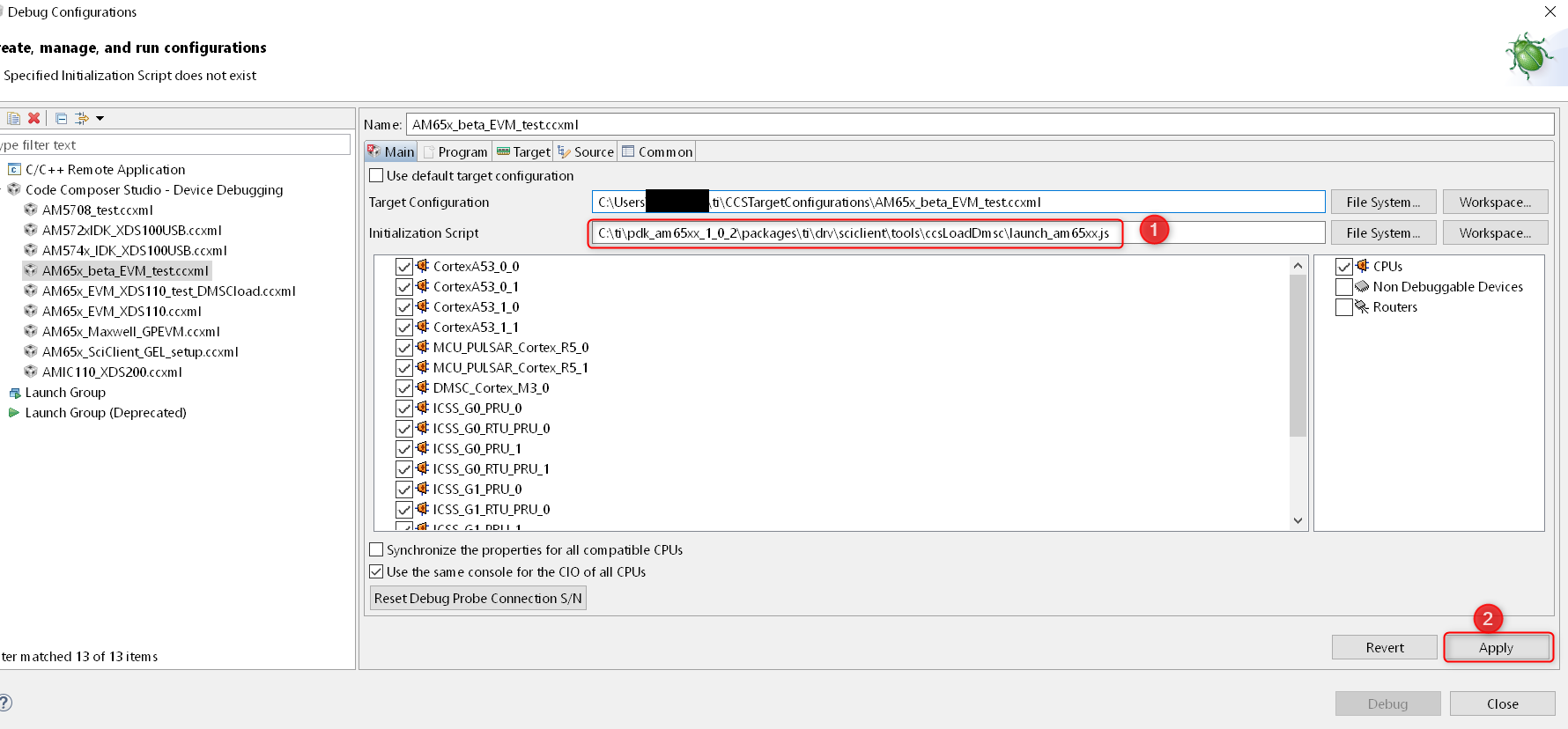

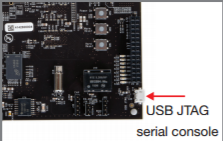

Once the examples are built, they can be run by loading and running the binaries using CCS through JTAG. Please refer to the section “Advanced AM65x Debug Setup with DMSC Firmware Load” of the TMDX654 EVM Hardware Setup Guide for setting up the JTAG.

Advanced AM65x Debug Setup with DMSC Firmware Load

IPC Message Queue Example:

ex02_messageq

Message queue example sends round-trip message from client to server and back. MessageQ example uses client/server pattern. It is a two processors example: the HOST and R5F-0 processor.

The R5F-0 processor is configured as server. It creates a named message queue. The server does not open any queues because it extracts the return address from the message header. The server returns all messages to the sender. It does not access the message pool.

The HOST processor is configured as client application. The client creates an anonymous message queue. The client also creates and manages the message pool. The client’s return address is set in the message header for each message before sending it to the server.

Here are the steps to run the example.

- Follow instructions above to build the IPC examples. The build will create the R5F-0 and HOST binaries under debug and release sub folders For example

- AM65XX_bios_elf\ex02_messageq\host\bin\debug\app_host.xa53fg : HOST A15 binary

- AM65XX_bios_elfex02_messageq\r5f-0\bin\debug\server_r5f-0.xer5fg : R5 binary

- Follow procedure to initialize platform and launch target configuration through steps outlined in the hardware setup guide referred above.

- Right click R5 core 0 and connect target.

- Load R5F-0 messageQ Example out file(server_r5f-0.xer5fg) onto R5F core 0.

- Right click CortexA53_0 and connect target.

- Load HOST messageQ Example out file(app_host.xa53fg) onto ARM CortexA53_0.

- Run both R5F-0 and HOST.

- On CCS –> Tools –> RTOS Object view (ROV).

- Suspend (halt) ARM Cortex_53 to view test messages on ROV Viewable Modules –>LoggerBuf

- Suspend (halt) R5F-0 and click on ROV icon to view log messages.

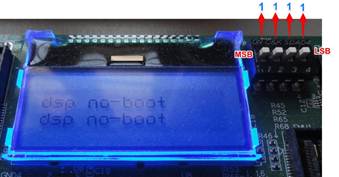

10.1.3. Taking the C66x Out Of Reset with Linux Running on the ARM A15¶

10.1.3.1. How to take the C66x DSP out of reset with Linux running on A15¶

This document describes the procedure to bring the C66x core out of reset after booting Linux, or at the u-boot prompt.These steps are necessary in to order to load an application on the C66x core, without interfering with the operation of Linux running on the A15.

Note

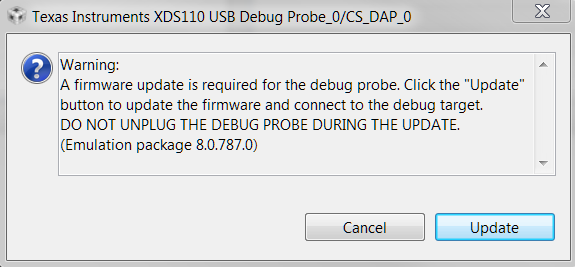

Prior to proceeding with the below instructions, please ensure that the latest Emulation Package is downloaded/installed through CCS. This will ensure the GEL files in your machine has the reset routines described below.

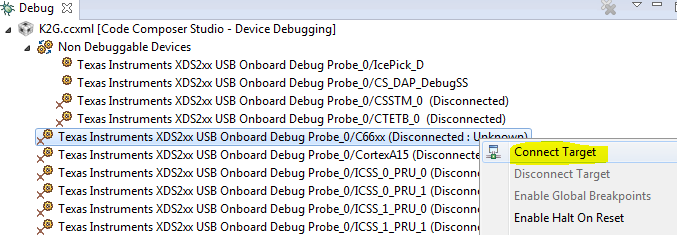

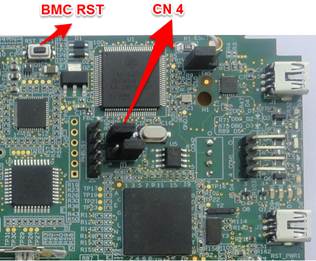

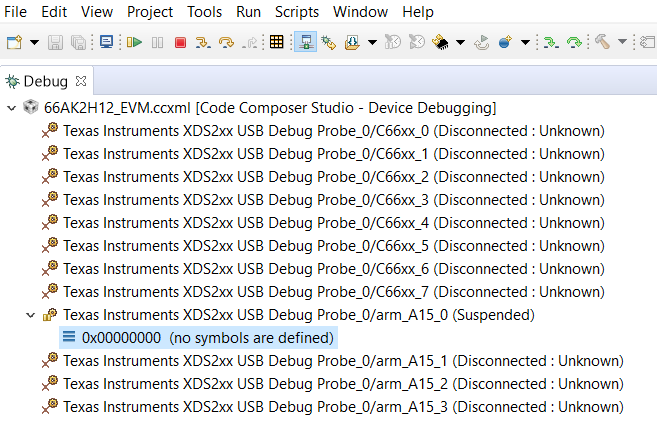

- Once Linux has booted, launch the target configuration.

- With the target configuration launched, right click on K2x.ccxml and select “Show all cores”

- This will bring up the Non-Debuggable Devices section. Right click and connect the CS_DAP_Debug_SS core.

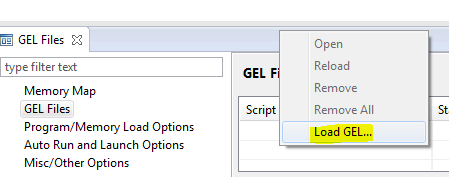

- Go to Tools>GEL files and load the evmk2x.gel file by right clicking on the GEL file window. The Gel file would typically be located in the CCS installation under \ccsv6\ccs_base\emulation\boards\evmk2x\gel\

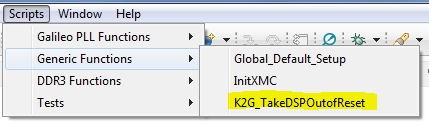

- Once the GEL has been successfully loaded, go to Scripts>default and select K2x_TakeDSPOutofReset.

- At this point the console would indicate that the DSP is out of reset.

- Now the DSP cores can be right-clicked and connected successfully.

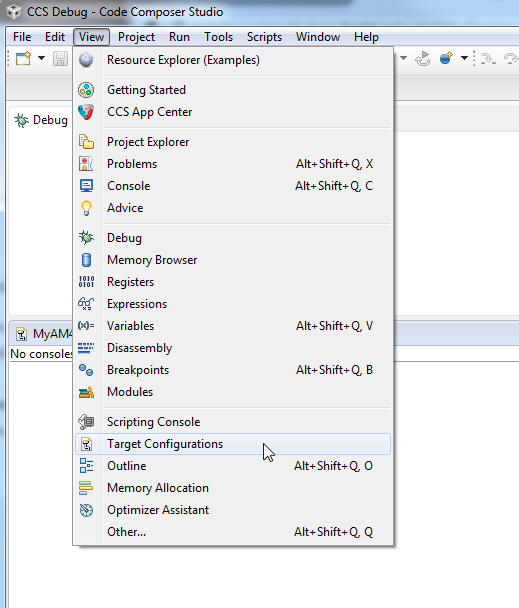

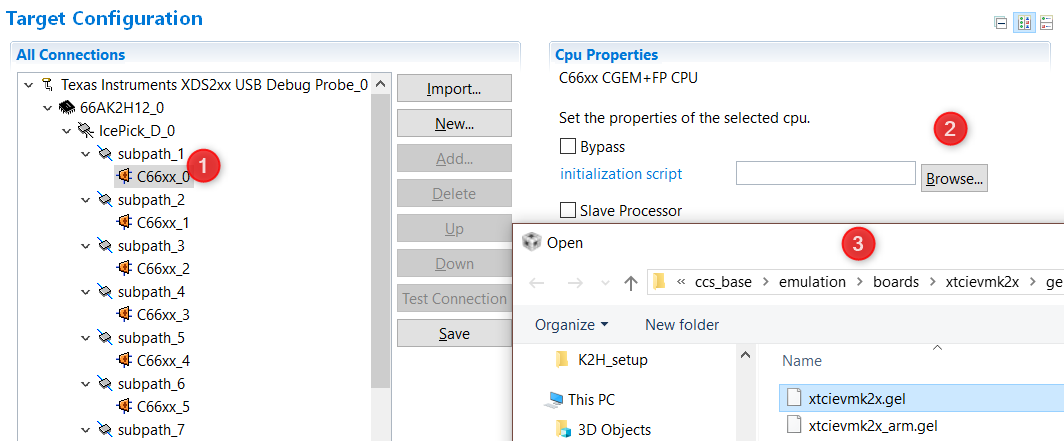

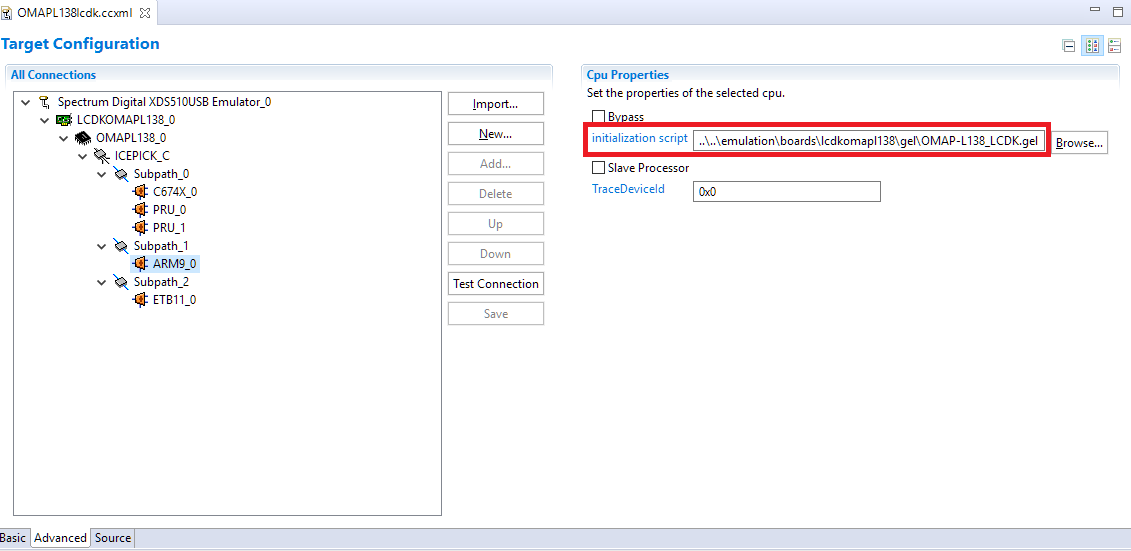

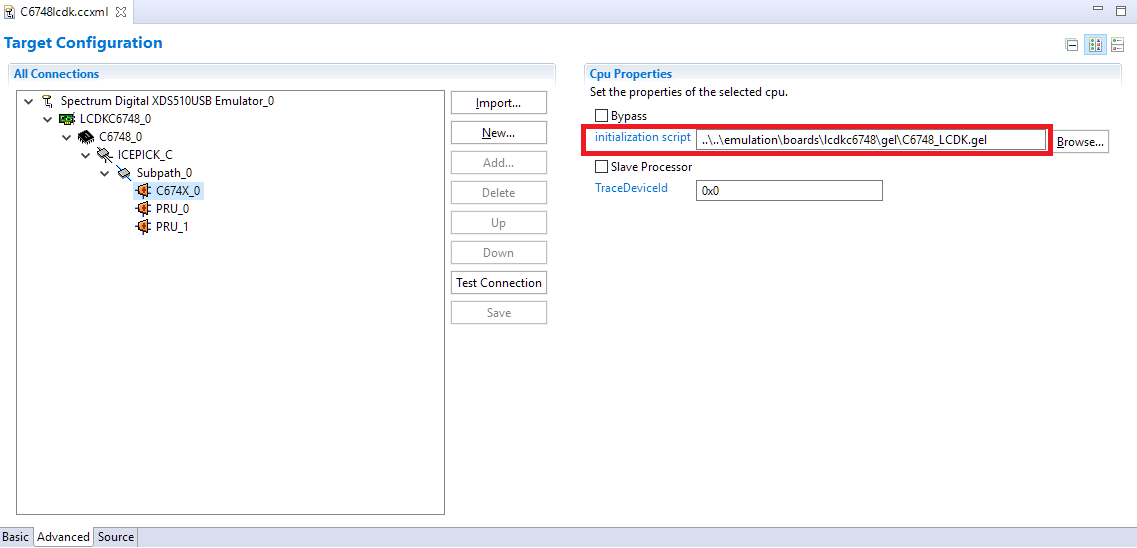

10.1.3.2. Target Configuration¶

Note

Once the DSP core is connected following the above out of reset routine, the DDR and PLL settings done by u-boot would be overwritten by what’s in the GEL. In order to avoid this, please ensure that the gel is NOT preloaded on the DSP core in the ccxml by leaving the initialization script blank.

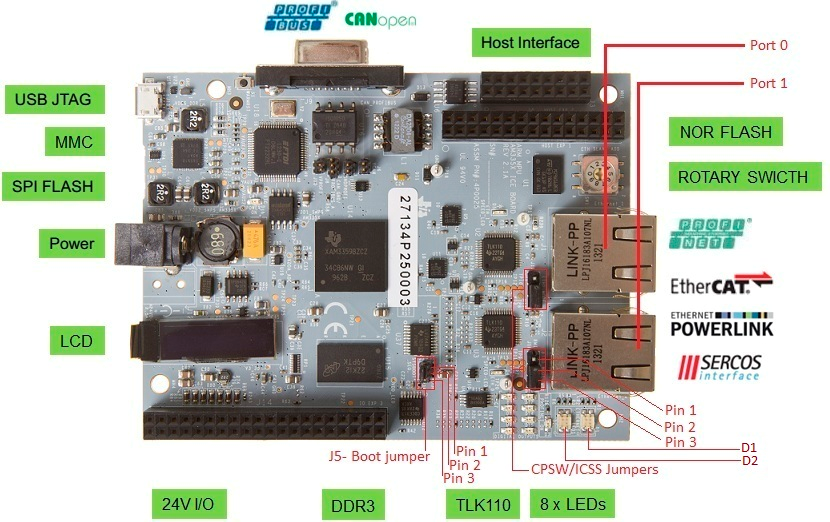

10.1.4. RTOS Customization: using an external input to trigger an interrupt on AM57x¶

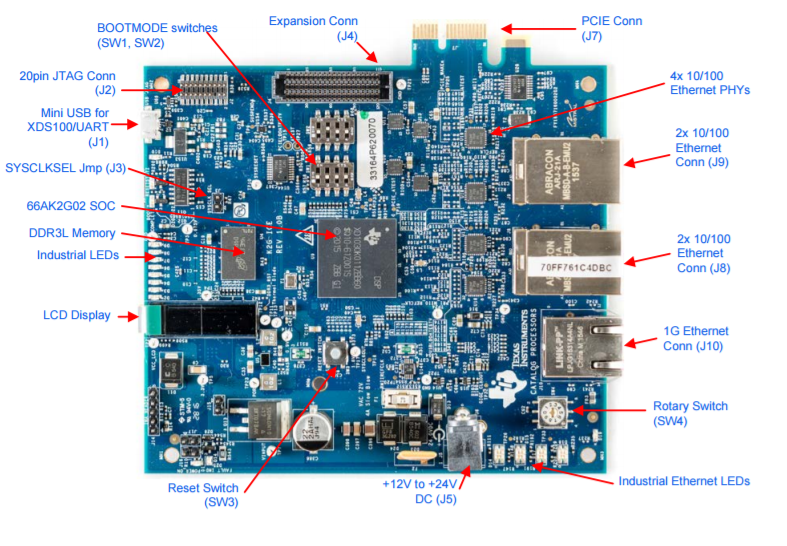

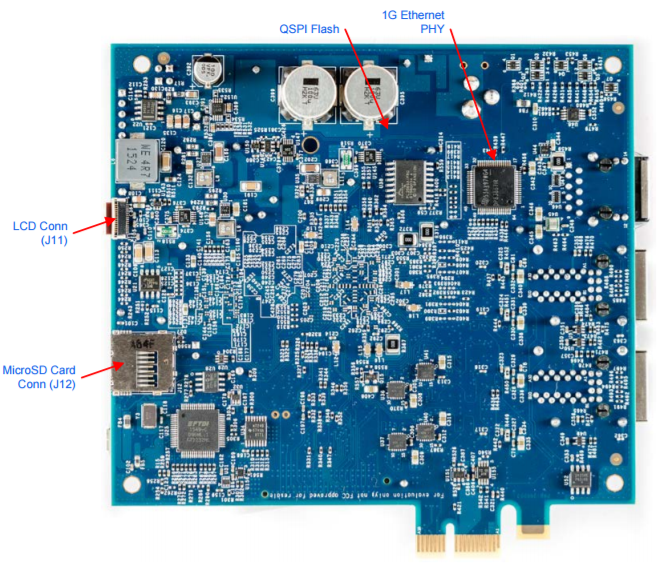

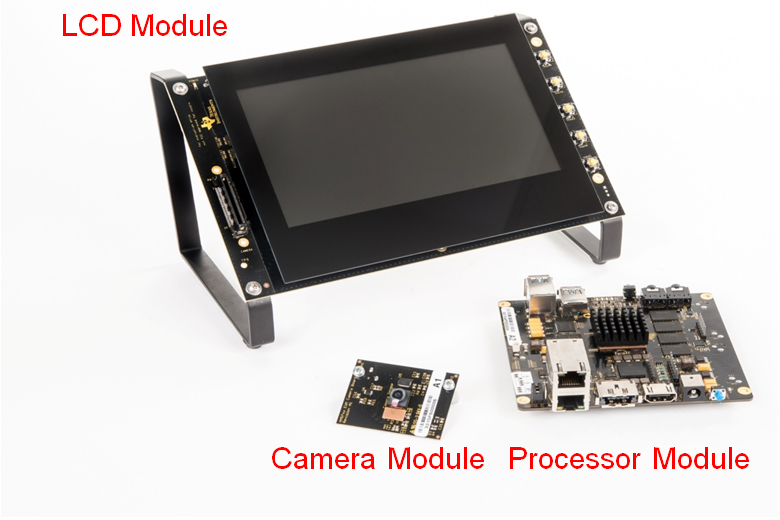

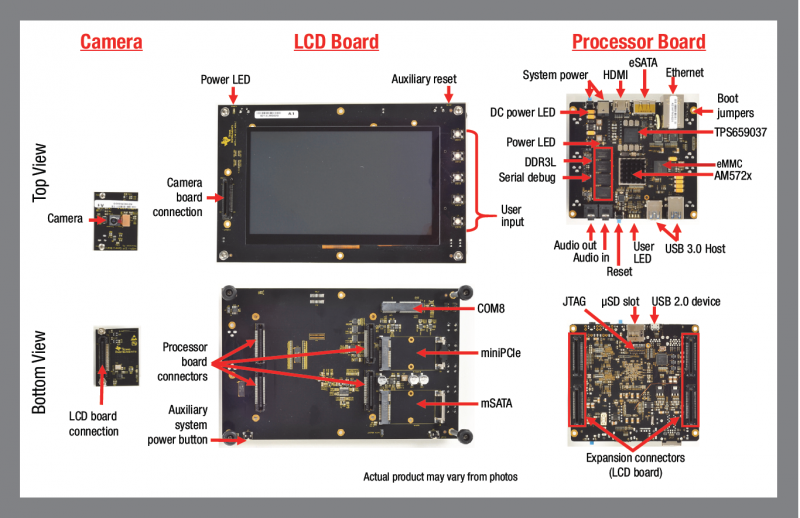

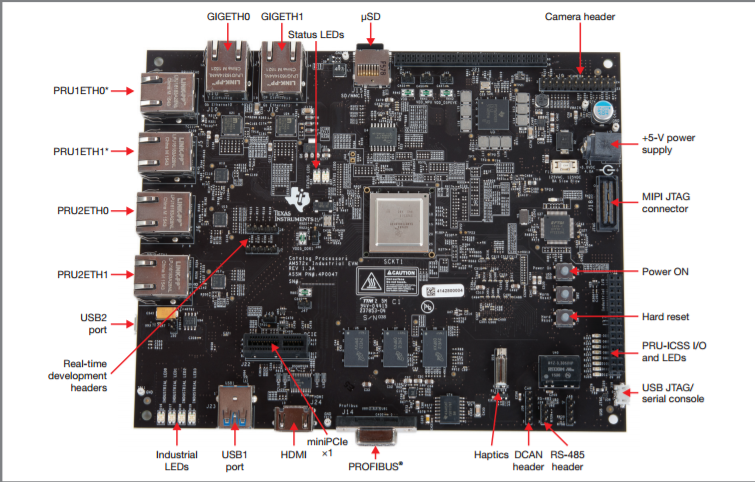

This note explains how to develop an example using a General-Purpose Input/Output (GPIO) pin to capture an external input event and generate an interrupt by modifying an existing RTOS GPIO driver LED blinking example. The hardware setup, software development procedures and testing are done using TI AM572x IDK EVM. The same process can be extended to other TI Sitara devices, TI EVMs or custom platforms as well.

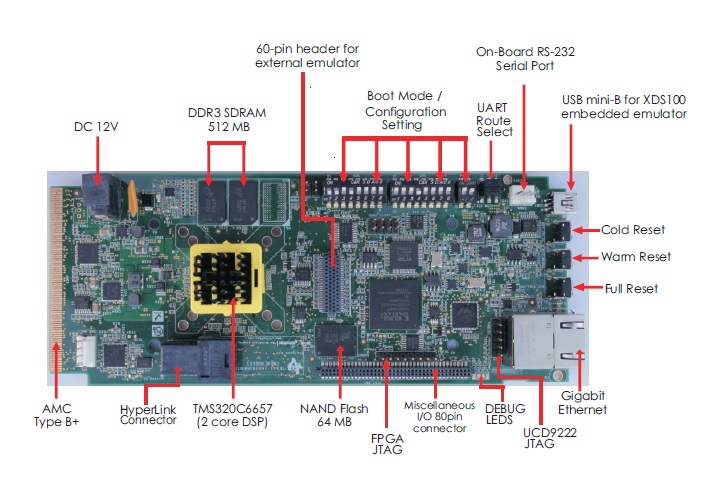

10.1.4.1. Hardware¶

The AM572x Industrial Development Kit (IDK) is used here for developing the example. The same expect to work with the AM574x IDK as well.

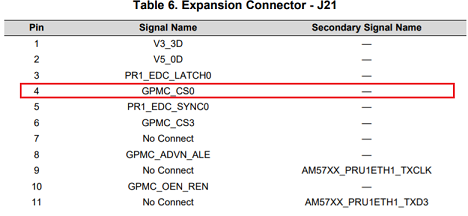

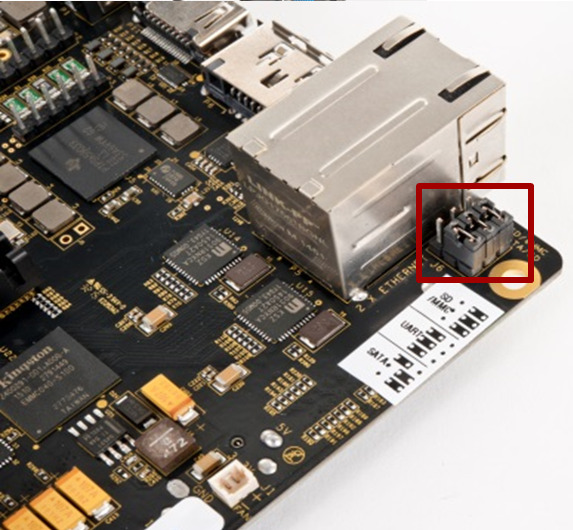

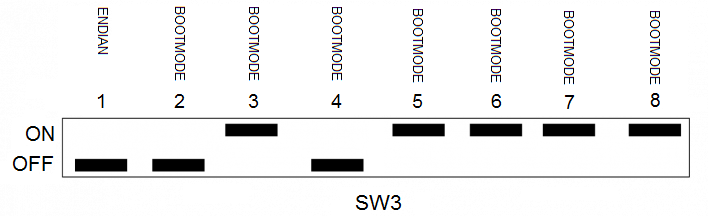

From the AM572x IDK EVM hardware user guide, the card has 3 push buttons: SW1, SW2 and SW3, but they all are used for different purposes. However, the card has a 60-pin female expansion connector J21, pins that are not used may be dedicated for GPIO input test purpose. Here J21 pin 4 is selected based on the following analysis:

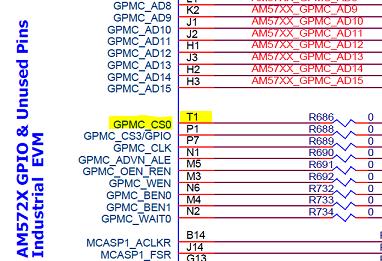

- The Pin 4 signal is labeled as GPMC_CS0 and is connected to AM572x chip ball T1 as shown in the schematic:

- From the AM5728 datasheet, T1 ball can be configured as GPMC_CS0 or GPIO2_19 based on different PINMUX modes.

10.1.4.2. Software¶

The GPIO LED blink example is served as the reference example and the test is developed on the ARM A15 core, it should work for other cores. This section discusses several typical steps involved in the software development work:

- PinMux configuration

- PRCM setup

- Re-build board library

- Application software development

PinMux configuration

The default PinMux file has to be modified for GPIO2_19 pin usage:

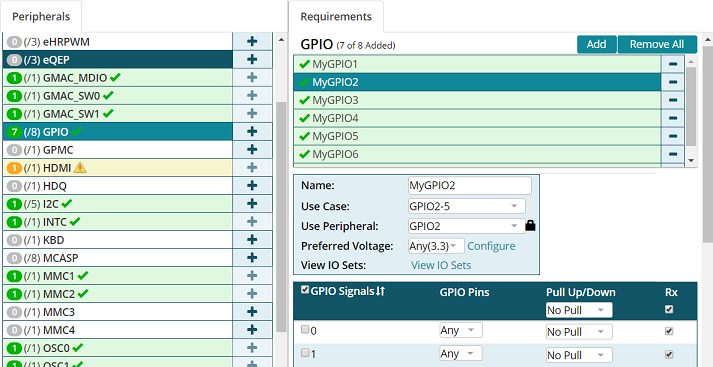

- Use the PinMux Utility to open the default PinMux file pdk_am57xx_1_0_x\packages\ti\board\src\idkAM572x\idkAM572x_SR2.0.pinmux (for the latest Rev 1.3B EVM)

- Select GPIO, then MyGPIO2:

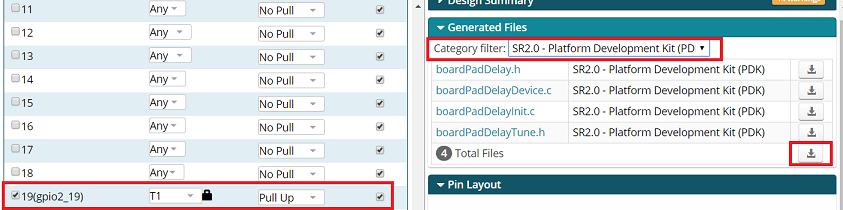

- Then, scroll down, set gpio2_19 with ball #T1, pull up and Rx direction.

- Finally, select Category filter as “SR2.0 – Platform Development Kit (PDK) and download the generated files.

- Four new files should be generated, with the only difference being a new pin configuration added in boardPadDelayInit.c file:

/* GPIO2 - gpio2_19 on T1 - MyGPIO2 */

{0x14B4, 0x6000E, {0x0, 0, 0}, {0x0, 0, 0}, {0x0, 0, 0}},

- Replace the same files under pdk_am57xx_1_0_x\packages\ti\board\src\idkAM572x with the new ones.

PRCM setup

Setup of the Power, Reset and Clock Management (PRCM) domain for newly added GPIO2 is required. The application code calls Board_init() API with a BOARD_INIT_MODULE_CLOCK flag to enable the clock domain. It is implemented in the Board_moduleClockInit() function inside pdk_am57xx_1_0_x\packages\ti\board\source\idkAM572x\idkAM572x_clock.c. It is found that GPIO2 is enabled already and no further code needed.

Re-build board library

The board library must be recompiled for the changes to take effect. This has several major steps:

- Setup the build environment by running setupenv script

- Build the library with make command (e.g. “make board”) and the output will be under pdk_am57xx_1_0_x\packages\ti\board\lib\idkAM572x\a15\release

10.1.4.3. Application software development¶

The GPIO LED blinking example (GPIO_LedBlink_idkAM572x_armTestProject) is used as the reference. The CCS project can be created by using pdkprojectcreate script, such as “pdkprojectcreate AM572x idkAM572x little gpio all arm”. Check PDK Example and Test Project Creation for details.

This LED blink example uses 2 GPIO pins. The first pin is used to periodically generate an interrupt. The second pin is an output pin connected to an onboard LED, which toggles between low and high inside the interrupt ISR, thus driving the LED. Note the first pin doesn’t accept any external input, but using software to write a register (GPIO_IRQSTATUS_RAW_n) to generate interrupt.

Also note from GPIO_idkAM572x_board.c, the rising edge is configured to generate interrupt:

GPIO_PinConfig gpioPinConfigs_1p3[] = {

/* Input pin with interrupt enabled */

GPIO_DEVICE_CONFIG(GPIO_GRN_LED_PORT_NUM_1P3, GPIO_GRN_LED_PIN_NUM_1P3) |

GPIO_CFG_IN_INT_RISING | GPIO_CFG_INPUT,

}

After understanding how the reference example works, the code can be modified to use the first pin to receive external input and trigger the interrupt, then the second pin works the same way to toggle the LED, visualizing the event input.

Code modifications: • GPIO_board.h: this file defines the GPIO pins for the test, the first pin needs to be updated

#define GPIO_INTR_LED_BASE_ADDR_1P3 (CSL_MPU_GPIO2_REGS)

#define GPIO_LED_PIN_NUM_1P3 (0x13U)

- GPIO_idkAM572x_board.c: this file also defines the GPIO pins for the test, the first pin needs to be updated

/* GPIO Definitions specific Rev1p3 Board */

/* GPIO pin number connected to the green LED */

#define GPIO_GRN_LED_PIN_NUM_1P3 (0x13)

/* GPIO port number connected to the green LED */

#define GPIO_GRN_LED_PORT_NUM_1P3 (0x02)

- main_led_blink.c: this is the main test program. The change is high-lighted in black, while the original code is in grey.

- Inside void gpio_test(UArg arg0, UArg arg1) routine there is a while(1) loop that continuously triggers the interrupt by software write. Since the new example relies on the external input event to trigger it, one can simply add another while(1) in front of it to block the original loop:

while(1); //New added loop

while(1)

{

if defined(SOC_AM574x) || defined(SOC_AM572x) || defined(SOC_AM571x)|| defined(SOC_AM335x) || defined(SOC_AM437x)

#if defined (idkAM572x) || defined (idkAM574x)

….

}

- Also inside the same void gpio_test(UArg arg0, UArg arg1) routine, one may add a debounce control before the test loop:

/* Write high to gpio pin to control LED1 */

GPIO_write((USER_LED1), GPIO_PIN_VAL_HIGH);

/* Add new debounce code here */

GPIOAppUpdateConfig(&gpioBaseAddr, &gpioPin);

GPIODebounceFuncControl(gpioBaseAddr, gpioPin, 1);

GPIODebounceTimeConfig(gpioBaseAddr, 255);

AppDelay(DELAY_VALUE);

GPIO_log("\n GPIO Led Blink Application \n");

After all the code changes, rebuild the test application. A GPIO_LedBlink_idkAM572x_armTestProject.out should be generated.

10.1.4.4. Test¶

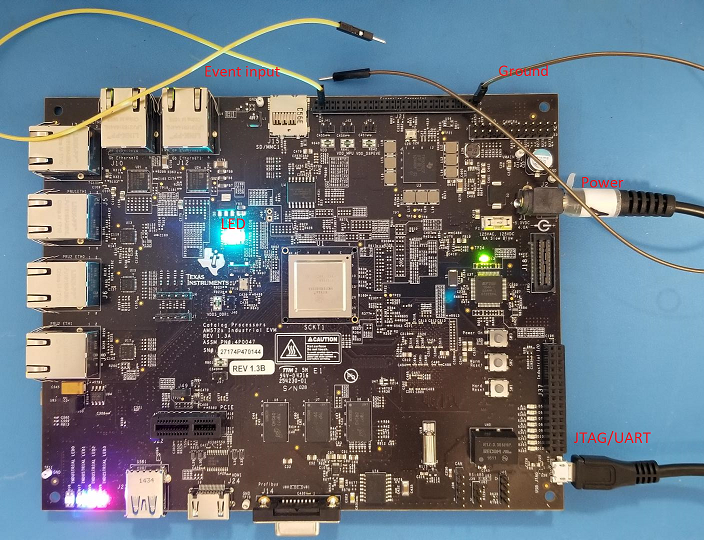

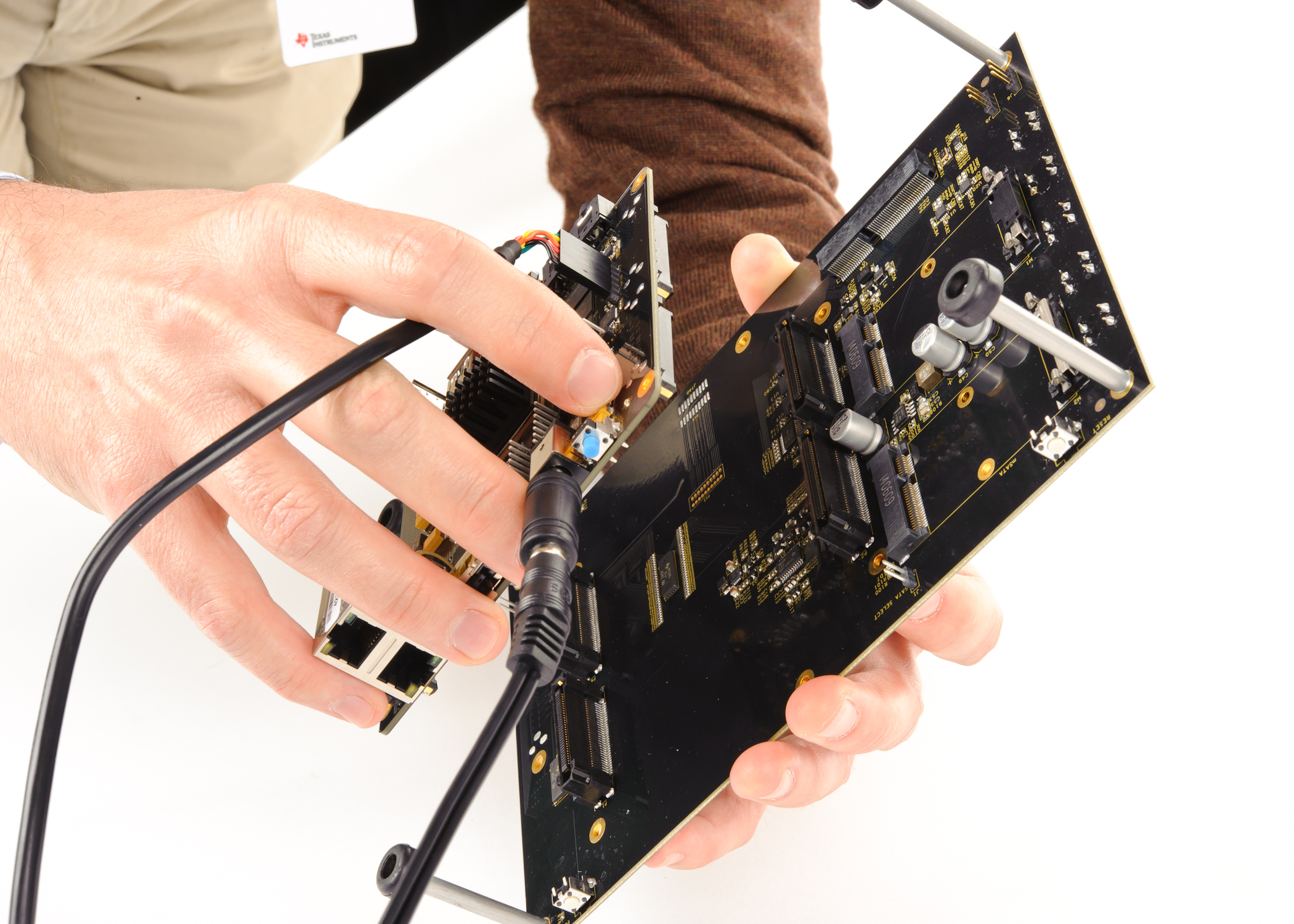

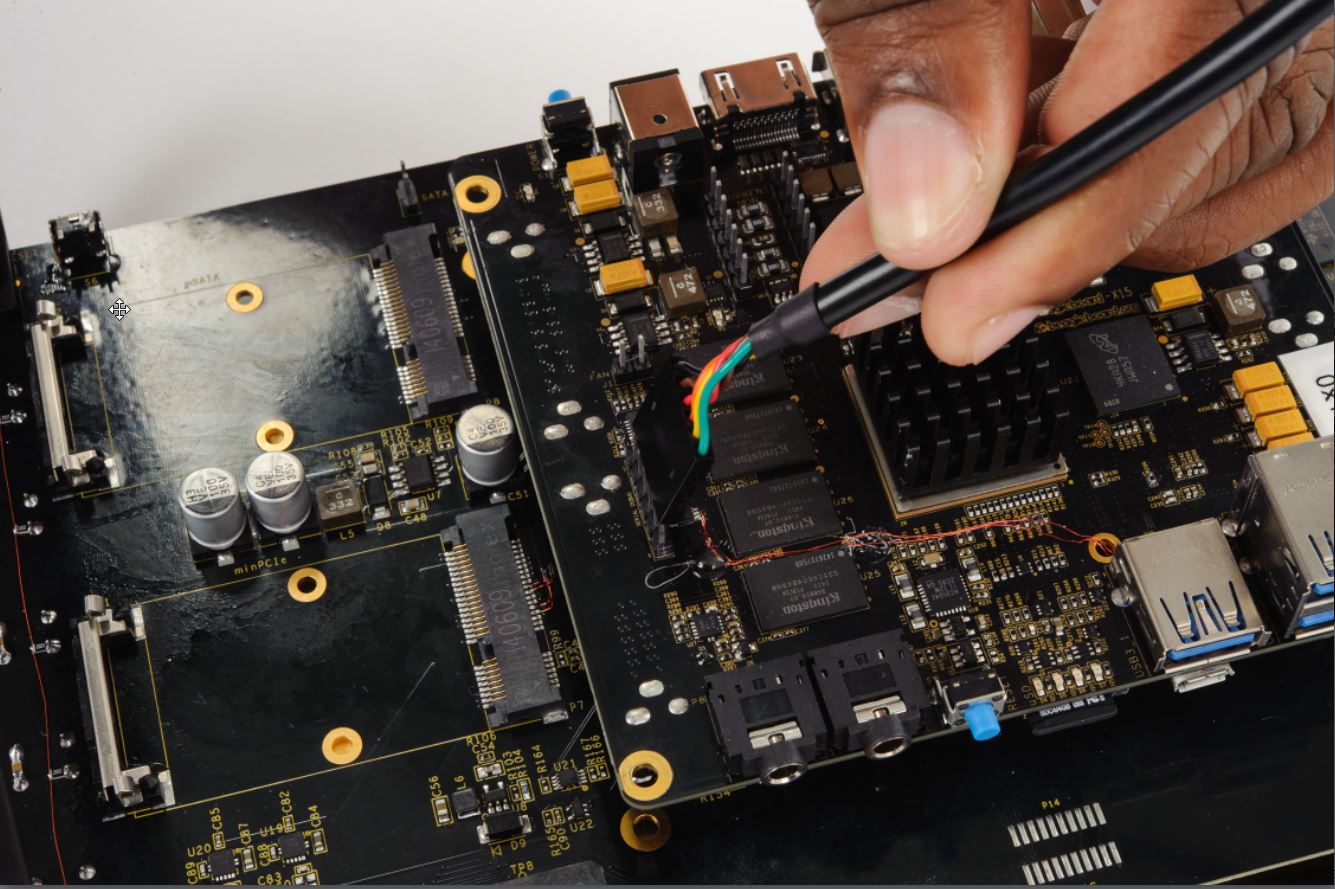

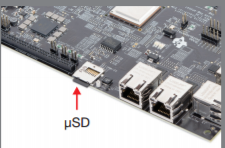

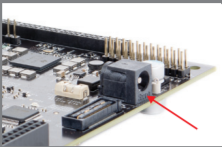

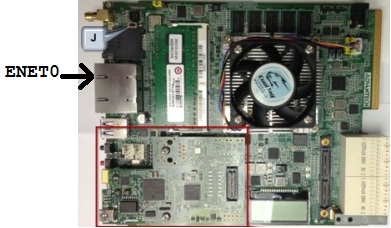

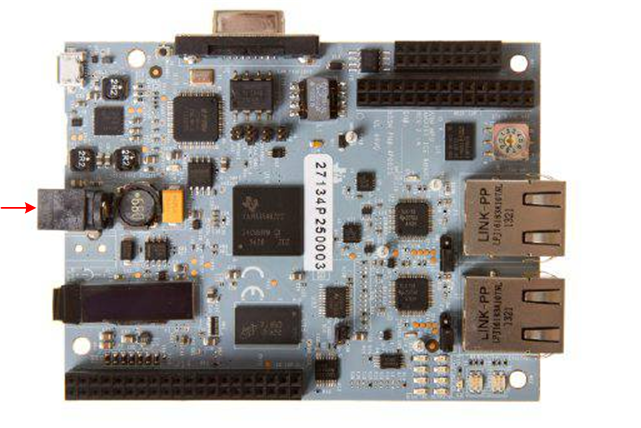

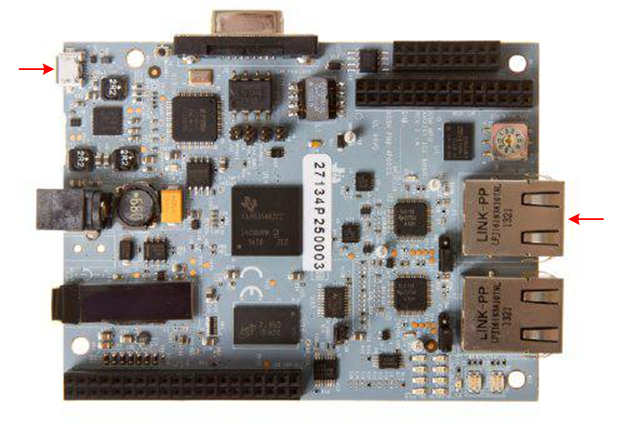

Test Setup The test setup using AM572x IDK EVM is depicted below:

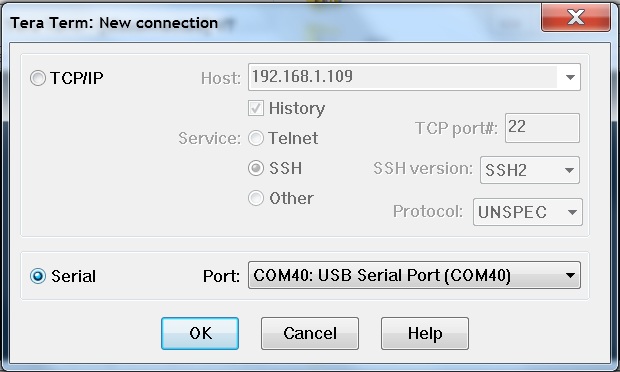

- The EVM is powered with a +5V power supply

- A micro USB cable is connected to the host PC for on-board XDS100v2 JTAG connection and UART console.

- A wire is connected to J21 pin4 as the event input. Another wire is connected to J21 pin 60 as the digital ground. When the two wires touch each other, pin 4 goes low, creating a GPIO falling edge. On the other hand, when the two wires are not touching, pin 4 goes high, creating a GPIO rising edge.

Test Procedure

- Connect to the A15_0 with a JTAG emulator and use the default GEL file to initialize the SOC.

- Load the test application (GPIO_LedBlink_idkAM572x_armTestProject.out) and run.

- Touch the two wires, then un-touch, the LED should flip the status and keep steady until next touch, un-touch cycle.

10.1.5. Run applications from DDR on R5 cores¶

Once the R5 core is out of reset, the R5 defaults to no execute permissions for the DDR memory space. The side effect of this is, that all code, from entry point till the code that sets up the MPU (Memory Protection Unit), has to be run from internal memory.

10.1.5.1. Run BIOS Applications from DDR on R5¶

In BIOS, the application sets up the MPU as per the memory configuration specified in the *.xs file (that is referred to in the applications bios config file). Once the MPU is setup by the app, the rest of the code can run from DDR.

To ensure that all code from entry point to MPU setup is run from internal memory, the text sections of the following libs must be placed in internal memory using the application’s linker command file.

Refer emac_linker_r5.lds for an example.

Note

Please note that you need to replace *<app>_per5f.oer5f with the corresponding file for your application. For eg, if the application’s .cfg file is emacUnitTest_r5.cfg, then the .oer5f file will be named emacUnitTest_r5_per5f.oer5f

You also need to update the *.xs file referred to by the applications .cfg file to make sure that the DDR has execute privileges. Please refer r5_mpu.xs for an example memory configuration. You could also make the applications .cfg file refer to the common .xs file, as shown in the example emacUnitTest_r5.cfg.

10.1.5.2. Run Baremetal Applications from DDR on R5¶

Baremetal applications have similar restrictions on running code from internal memory till the MPU is configured, just like BIOS applications. For best comaptibility, however, make sure that the entry point is always the reset vector, and that the code that sets up the DDR access permissions in the MPU resides completely within 0x100 bytes of the entry point.

For applications that find the default R5 configuration setup by the CSL sufficient, there is another method that can be used to execute an application from DDR. If the bootloader (SBL) is re-built using the SBL_SKIP_MCU_RESET compile option (by enabling the corresponding line in sbl_component.mk, then SBL will branch to the application entry point without resetting the R5 core.

In this scenario, as the R5 core was already setup when the SBL invoked CSL init, the app can execute directly from DDR, right from its entry point. However, the app must take care not to redo the R5 initialization using CSL init, as the CSL initialization code assumes that the R5 registers are at their reset default values. This can be done by simply defining an empty __mpu_init function in the baremetal application. Refer sbl_smp_r5.asm for an example.

10.2. Host¶

10.2.1. Setup¶

10.2.1.1. Setup CCS for EVM and Processor-SDK RTOS¶

10.2.1.1.1. Overview¶

This page provides information on configuring CCS to work with both the EVM and the Processor-SDK for RTOS.

10.2.1.1.2. Discovering SDK products¶

10.2.1.1.2.1. CCS and SDK installed in same directory¶

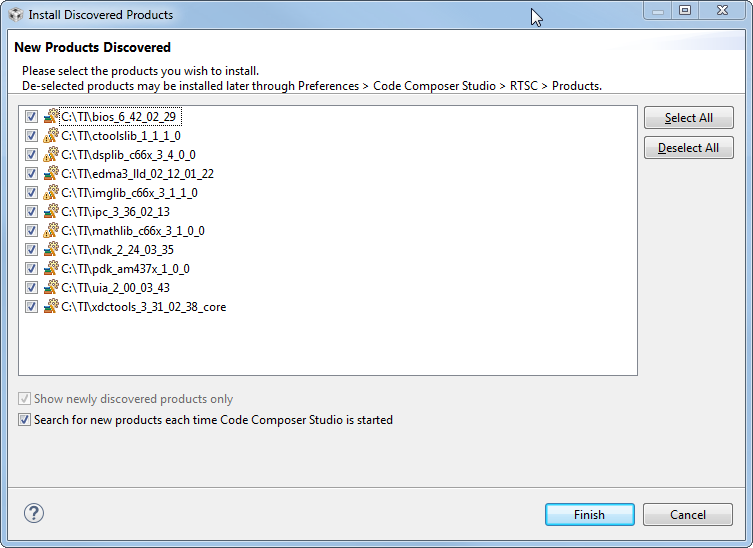

After installing the Processor-SDK RTOS, start CCS and it will automatically detect the newly installed components (products):

10.2.1.1.2.2. CCS and SDK installed in different directories¶

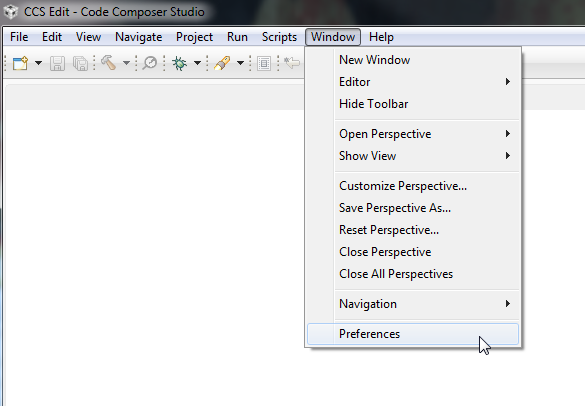

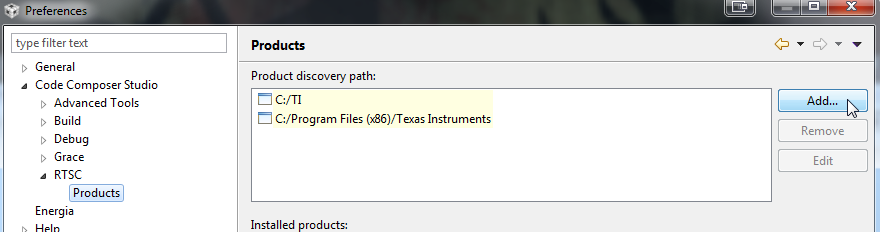

If you chose to install the SDK package in a different folder from where CCS is installed (e.g. C:\TEMP\RTOS-SDK\am57x), then you will need to add the path to the search path for CCS to locate the new packages. The screenshots below demonstrate the process to setup the CCS environment; the sequence for a Linux host is the same.

10.2.1.1.2.2.2. Enter path to SDK¶

In the Preferences window, select “Code Composer Studio -> RTSC -> Products” in the panel on the left. Then, press the “Add” button on the panel on the right:

10.2.1.1.2.2.3. Verify components¶

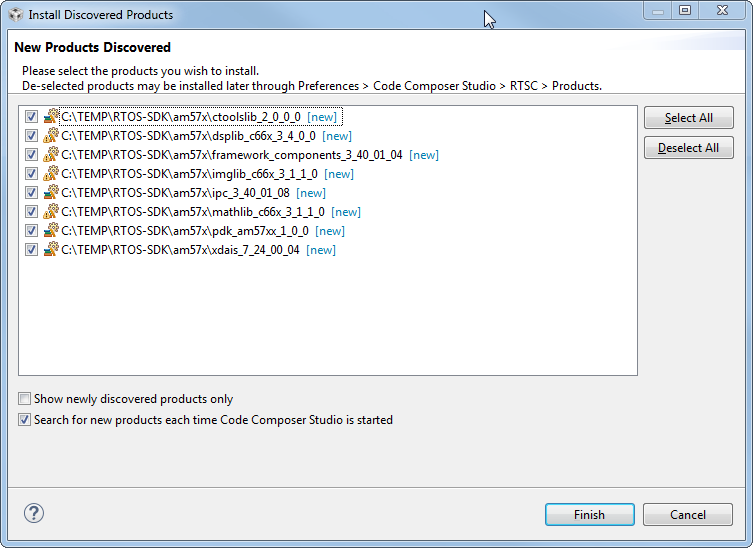

Next, verify the newly discovered products. If everything is correct, press the “Finish” button on the bottom:

10.2.1.1.2.2.4. Restart CCS¶

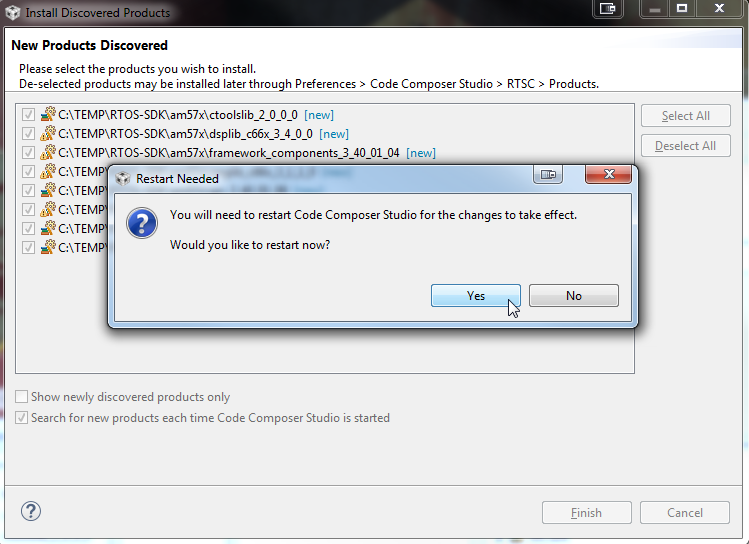

When prompted, restart CCS for changes to take effect. You will see newly discovered products from the custom path.

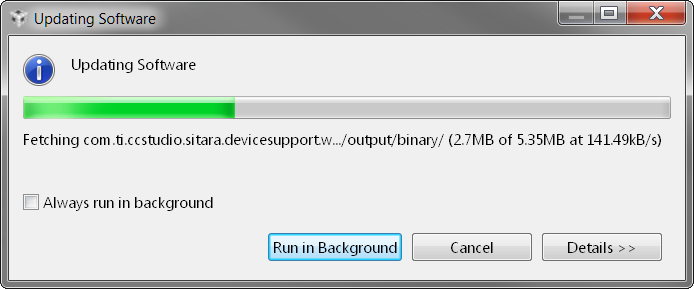

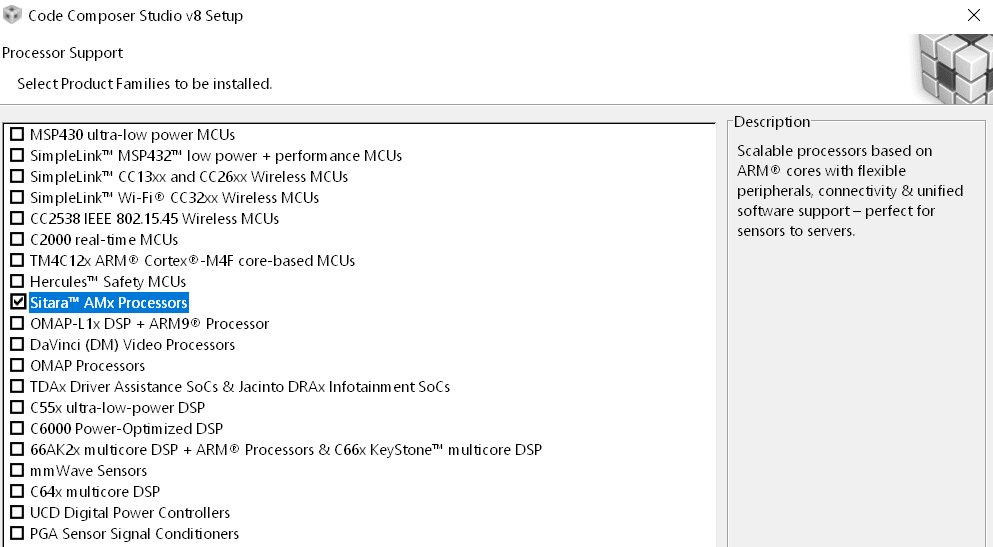

10.2.1.1.2.3. Install Latest Emulation Package and Sitara Device Support Package¶

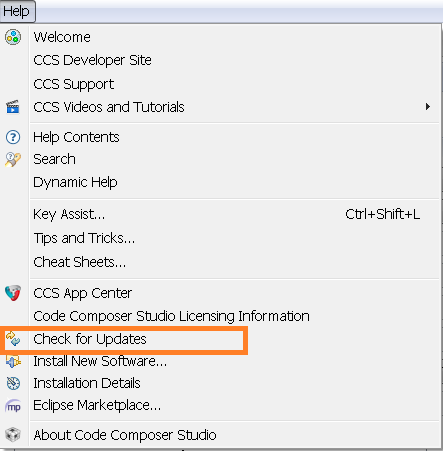

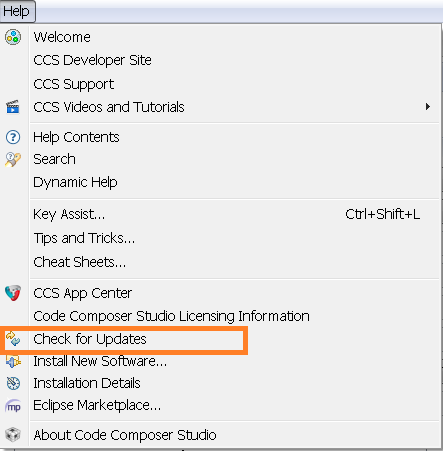

1. In CCS, navigate to Help -> Check for Updates and select “Sitara device support” and “TI Emulators” and click Next.

2. Click “Next” again, select “I accept the terms of the license agreements” and click Finish to begin the installation.

3. You may be prompted to restart CCS for the updates to take effect. Click “Restart Now” when prompted to complete the installation.

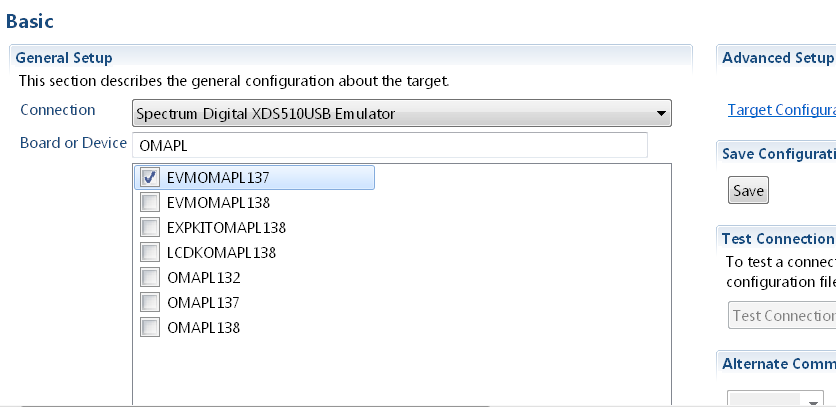

10.2.1.1.2.4. Create Target Configuration File for EVM¶

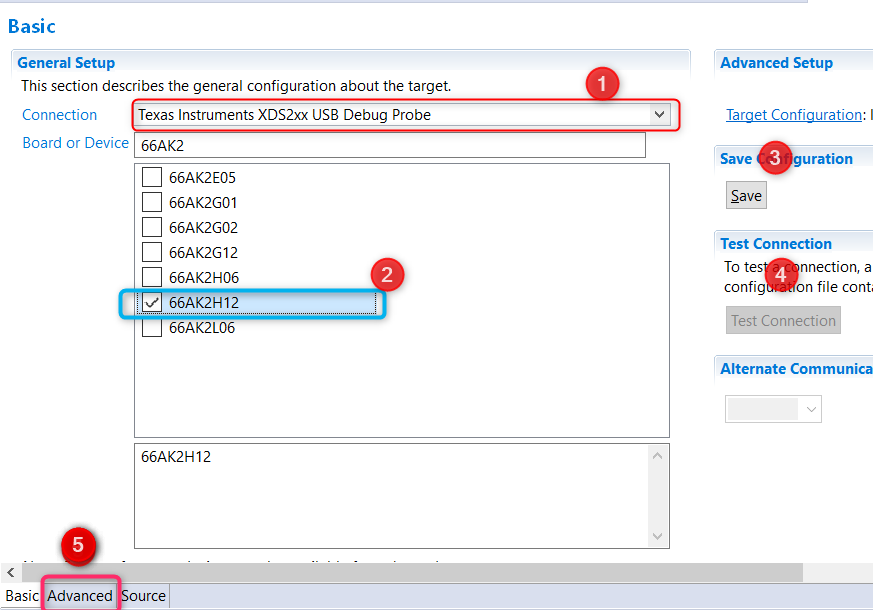

In CCS, you need to create a Target Configuration for your EVM to be able to connect to the target. This configuration defines your:

- Connection to the target (XDS, FET, etc.)

- Target device (AM437x GP EVM, AM57x GP EVM, etc.)

- GEL file for hardware initialization. A GEL file is basically a “batch file” that sets up the CCS debug environment including memory map, PLL, clock, etc.

CCS comes with basic configuration that can be used to configure your particular setup. In the example below, we provide details for a GP AM437x EVM; configuration information for other supported EVMs are also provided as needed.

For EVM specific instructions, refer to the Hardware User’s Guide for your EVM

Note

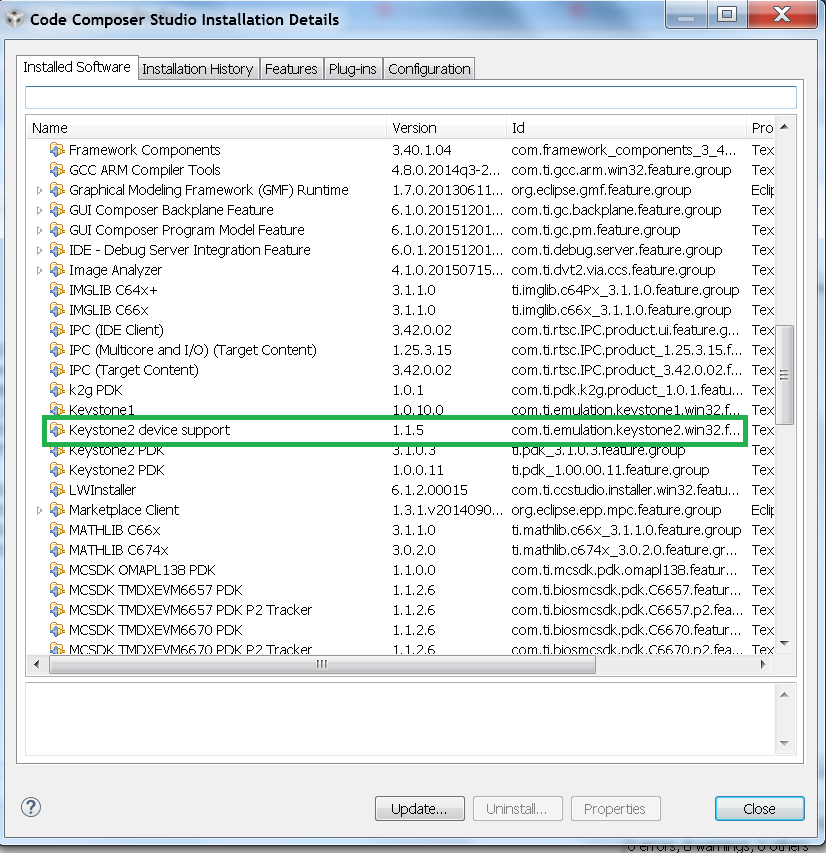

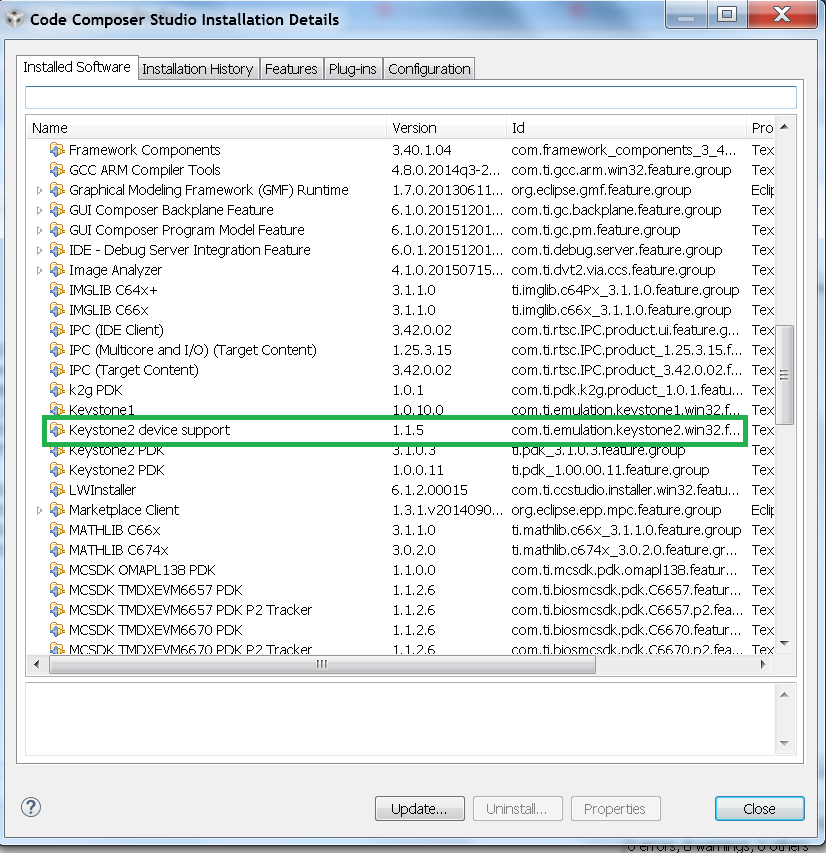

Note for K2G devices: If using CCS v6.1.2 and Keystone2 device support v1.1.7, 66AK2G02 would not show up in the list of devices when creating the target configuration. This is due to an incompatibility in the XML parser in CCS v6.1.2 with the K2G device xml. In order to work-around this issue, make the change in 66AK2G02.xml as illustrated below in order to have 66AK2G02 display in the device list. This problem does not exist in CCS v6.1.3 onwards as the XML parser has been updated.

C:\ti\ccsv6\ccs_base\common\targetdb\devices\66AK2G02.xml

Line #1

<?xml version="1.1" encoding="UTF-8" standalone="no"?>

to

<?xml version="1.0" encoding="UTF-8" standalone="no"?>

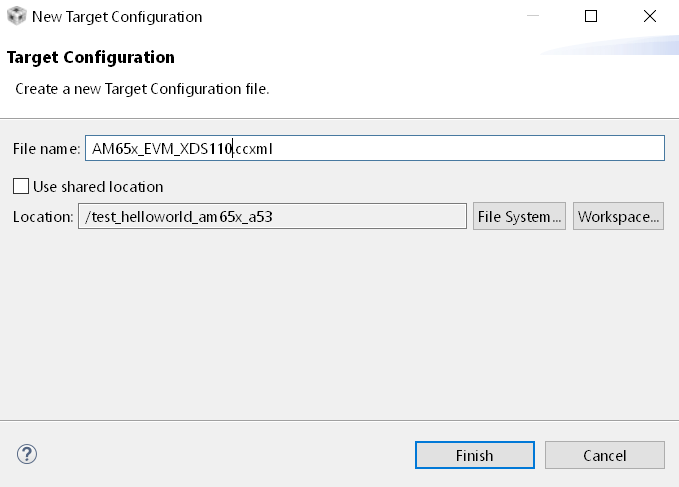

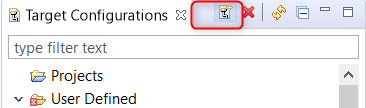

10.2.1.1.2.4.1. Open new target configuration file¶

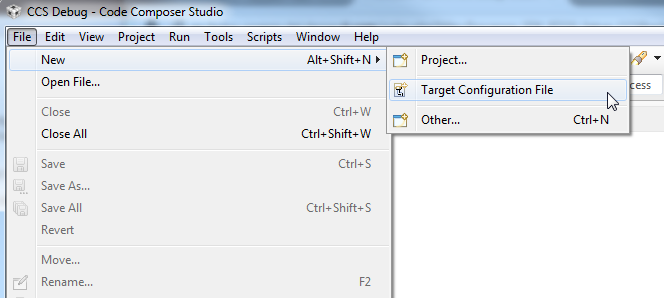

From CCS, select “File -> New -> Target Configuration File”:

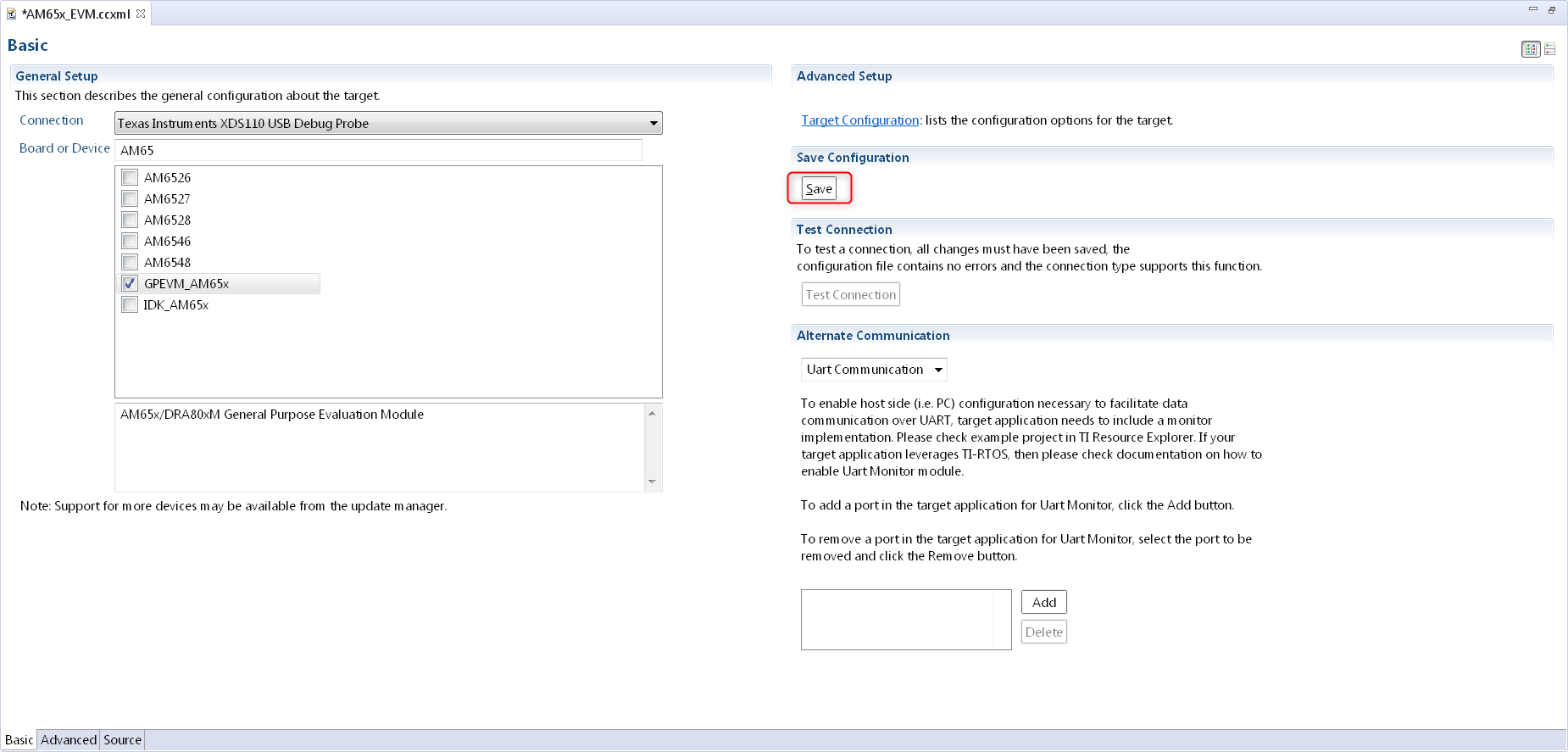

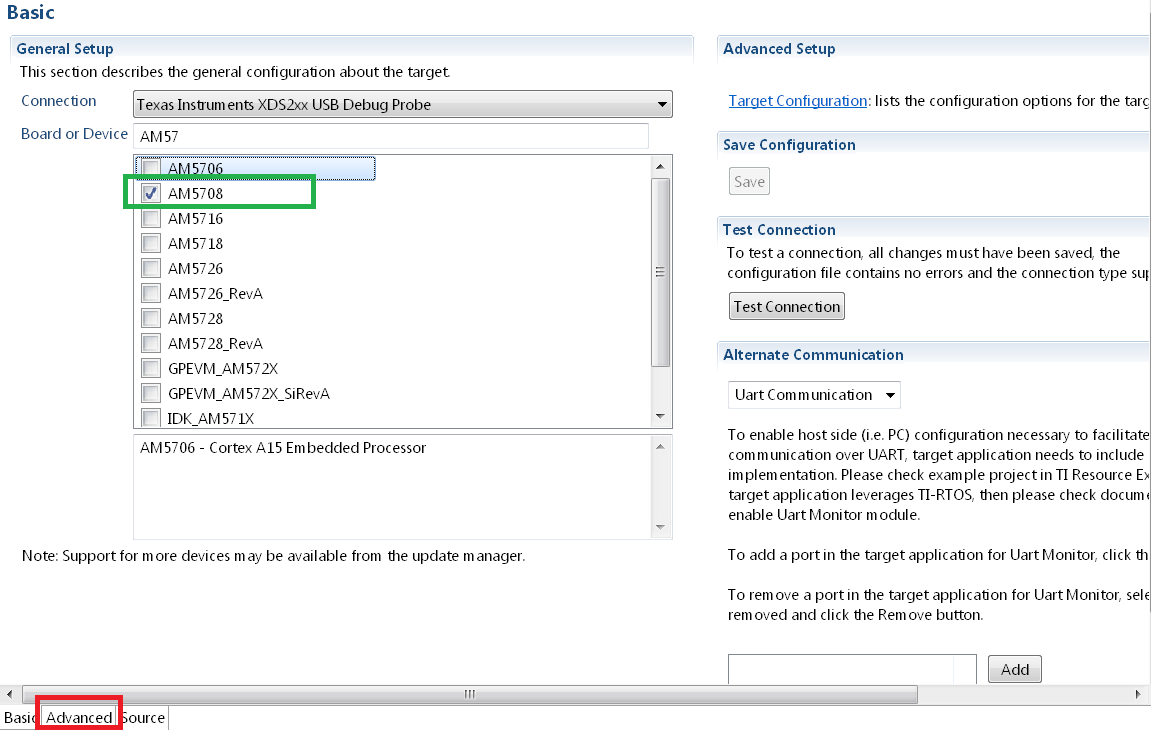

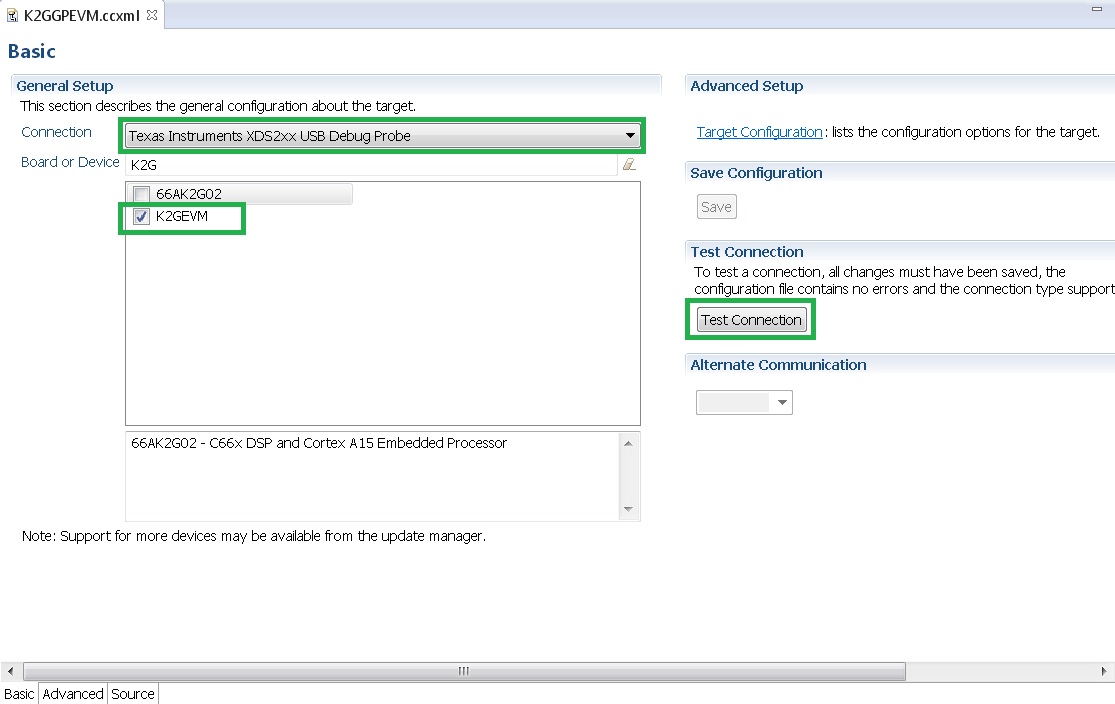

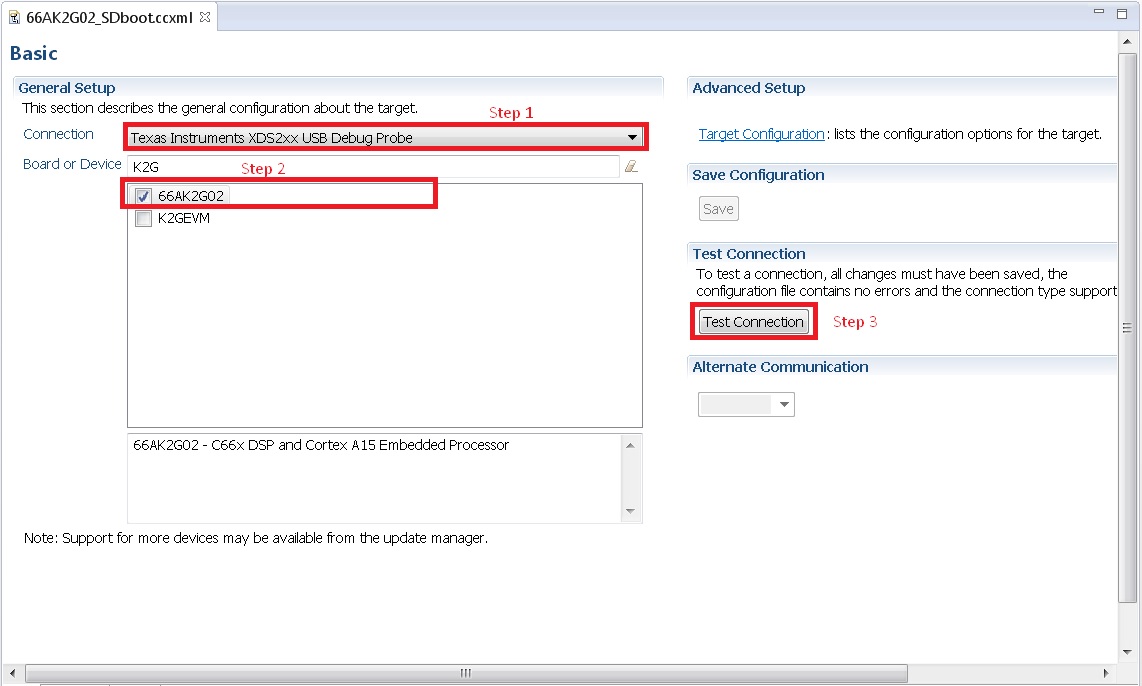

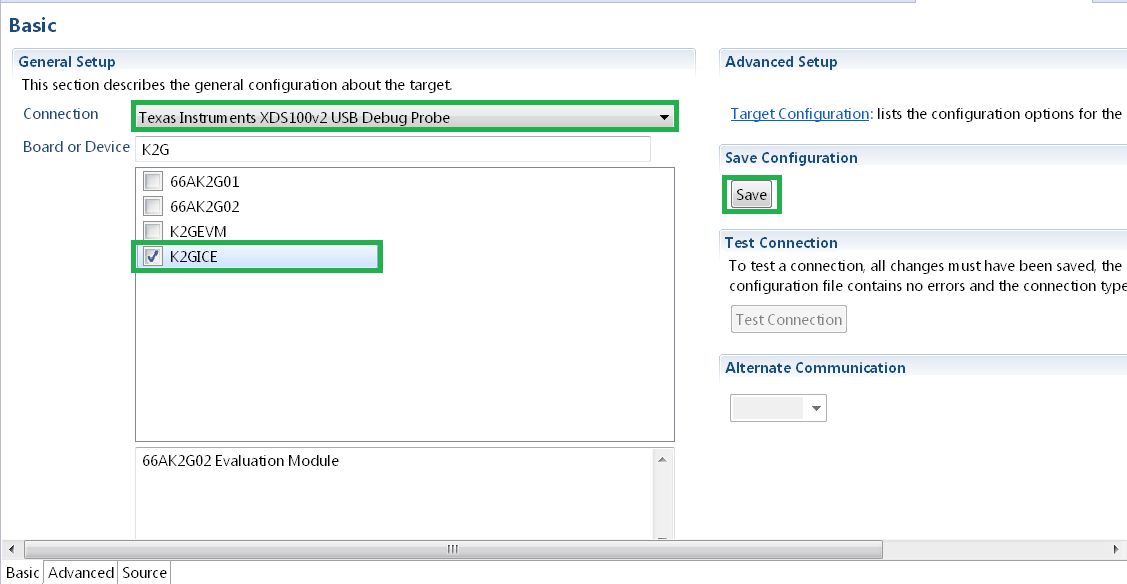

10.2.1.1.2.4.2. Select target configuration options¶

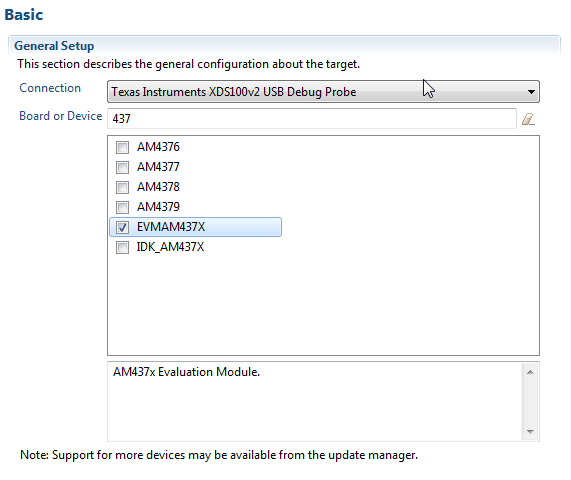

The AM437x GP EVM supports embedded XDS100V2 USB Emulation through the MicroUSB AB connector. Select

- Connection: Texas Instruments XDS100v2 USB Debug Probe

- Board or Device: EVMAM437X

Useful Tip

If you enter the starting numbers of your device in the Board or Device field, the list will show the relevant subset.

Here is a table showing configuration information for all supported EVMs in the Processor-SDK RTOS:

| EVM | Connection | Board |

|---|---|---|

| AM65x EVM | Texas Instruments XDS110 USB Debug Probe | GPEVM_AM65x |

| AM65x IDK | Texas Instruments XDS110 USB Debug Probe | IDK_AM65x |

| GP335x | External Emulator Supplied by User. EVM includes a TI 20 pin JTAG connector. | EVMAM3358 |

| ICE335x | Texas Instruments XDS100v2 USB Debug Probe | ICE_AM3359 |

| SK335x | Texas Instruments XDS100v2 USB Debug Probe | SK_AM3358 |

| BBB | External Emulator Supplied by User. EVM includes a TI 20 pin JTAG connector. | BeagleBone_Black |

| GP437x | Texas Instruments XDS100v2 USB Debug Probe | EVMAM437X |

| IDK437x | Texas Instruments XDS100v2 USB Debug Probe | IDK_AM437X |

| GP572x | External Emulator Supplied by User. EVM includes a TI 20 pin JTAG connector. | GPEVM_AM572X |

| X15 | External Emulator Supplied by User. EVM includes a TI 20 pin JTAG connector. | GPEVM_AM572X |

| IDK572x/IDK574x | Texas Instruments XDS100V2 USB Debug Probe External Emulator Supplied by User. EVM includes a 60-pin MIPI JTAG connector | IDK_AM572X/IDK_AM574X |

| C665x EVM | Texas Instruments XDS2xx USB Onboard Debug Probe | TMS320C6657 |

| C667x EVM | L w/ XDC100: Texas Instruments XDS100v1 USB Emulator LE/LXE with XDS560: Blackhawk XDS560v2-USB Mezzanine Emulator | TMS320C6678 |

| K2E EVM | Texas Instruments XDS2xx USB Onboard Debug Probe | 66AK2E05 |

| K2H EVM | Texas Instruments XDS2xx USB Onboard Debug Probe | 66AK2H12 |

| K2L EVM | Texas Instruments XDS2xx USB Onboard Debug Probe | TCI6630K2L |

| K2G GP EVM | Texas Instruments XDS2xx USB Onboard Debug Probe | 66AK2G02 |

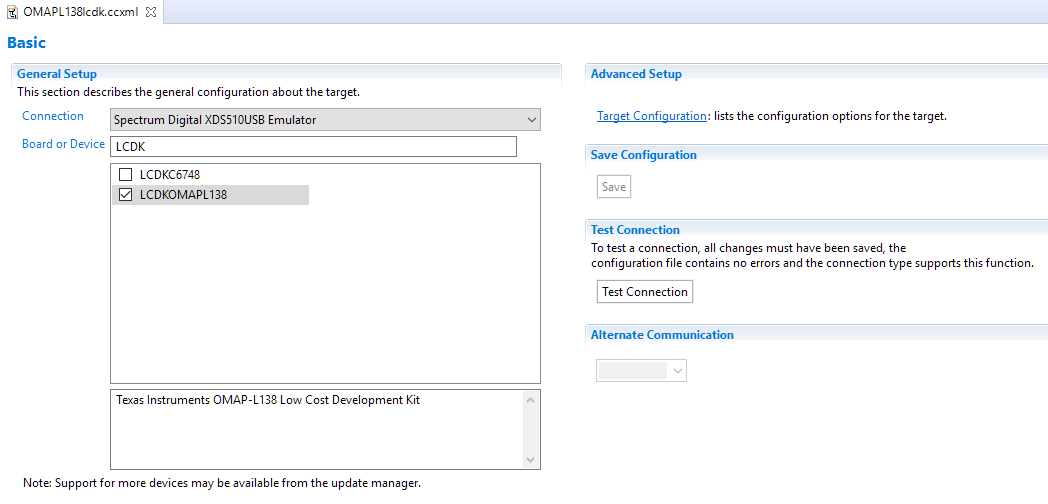

| OMAPL137 EVM | Spectrum Digital XDS510USB Emulator | OMAPL137SK |

| OMAPL138 LCDK | External Emulator Supplied by User. EVM includes a TI 14 pin JTAG connector. | OMAPL138LCDK |

10.2.1.1.2.4.3. Save target configuration¶

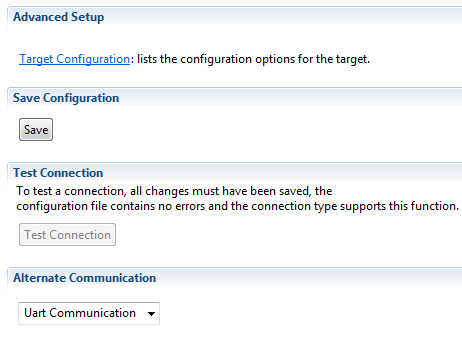

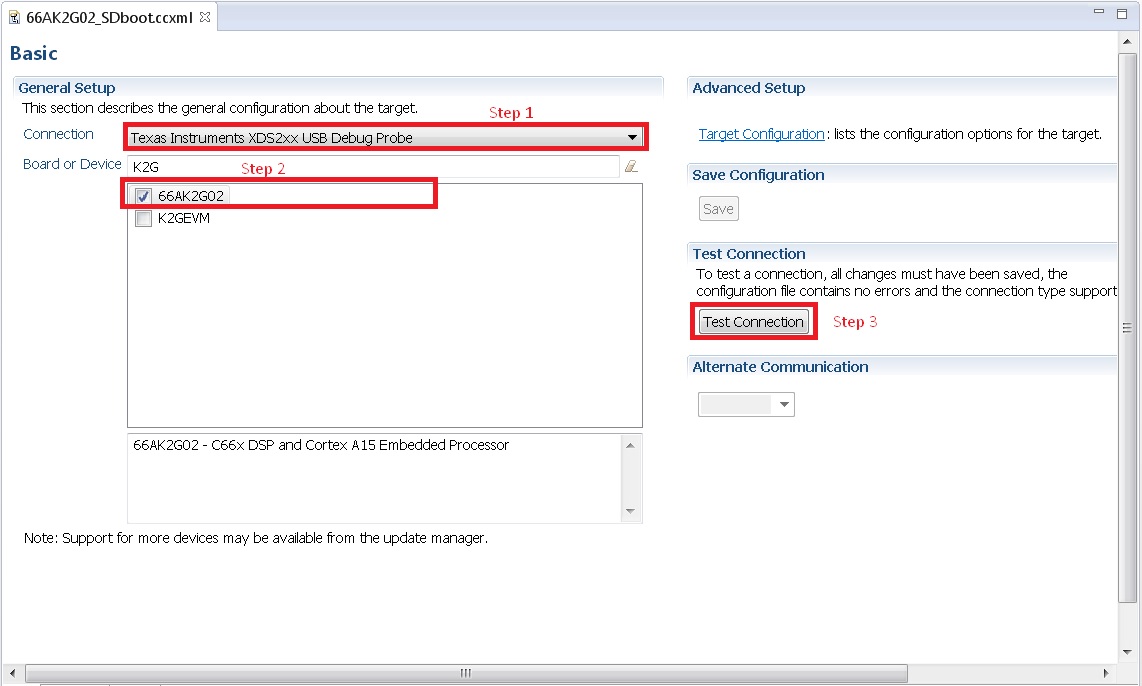

Next, save the target configuration by pressing the Save button:

10.2.1.1.2.4.4. Test target configuration¶

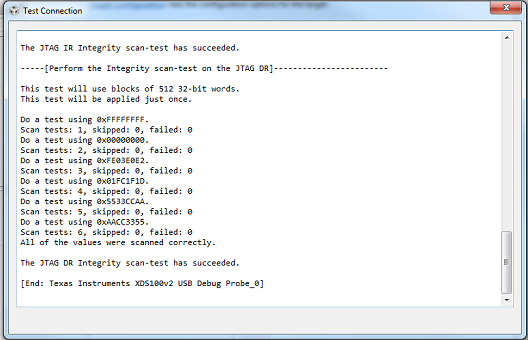

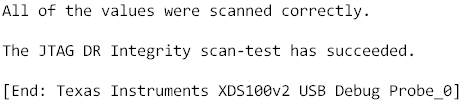

Next, test the target configuration by pressing the Test Connection button. This will confirm that you have successfully created an emulator connection with your board.

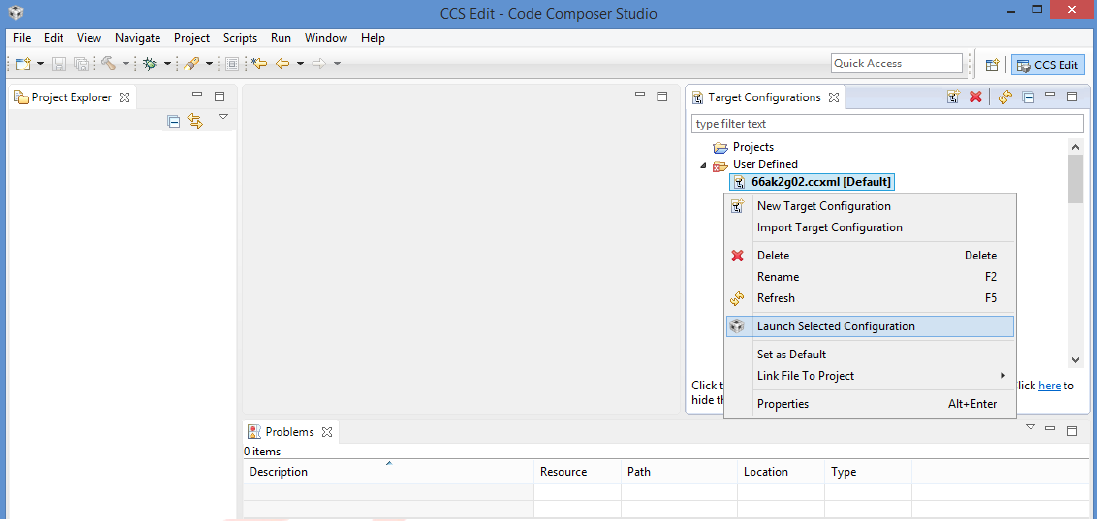

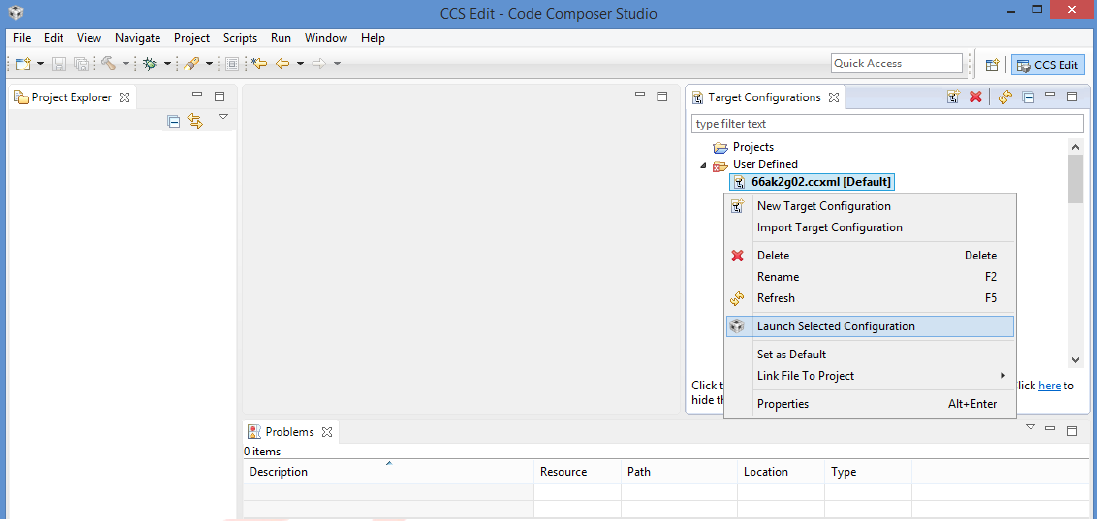

10.2.1.1.2.4.6. Launch target configuration¶

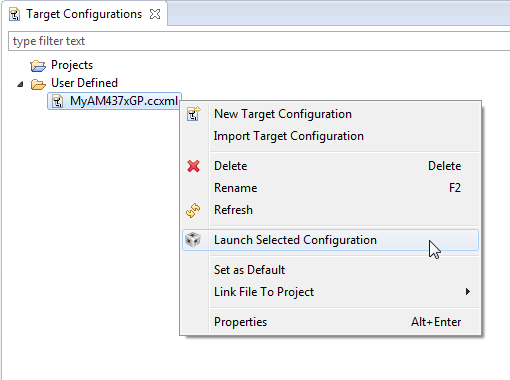

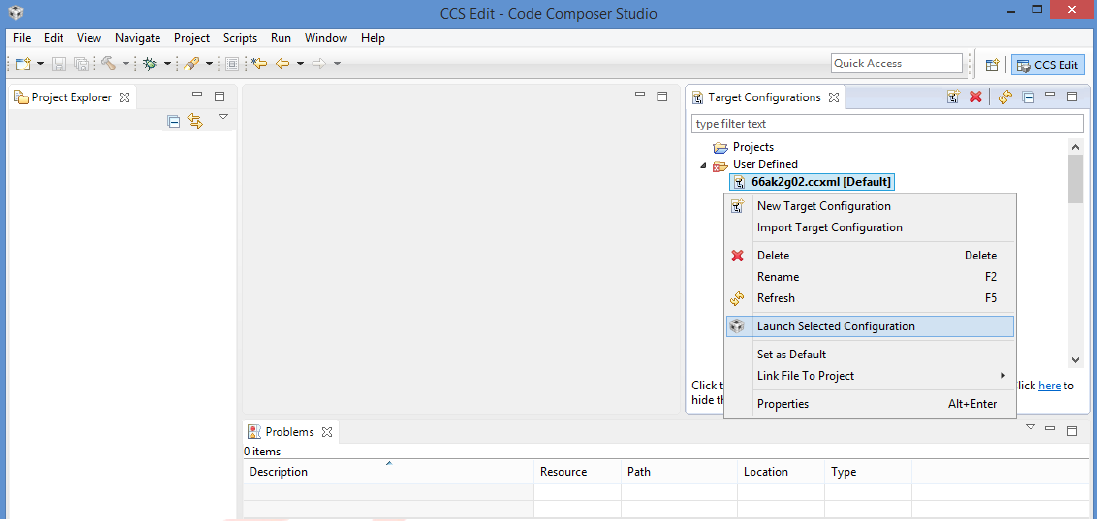

Open “User Defined” list and right click on the target configuration file that was just saved and select “Launch Selected Configuration”:

10.2.1.1.2.4.7. Connect target¶

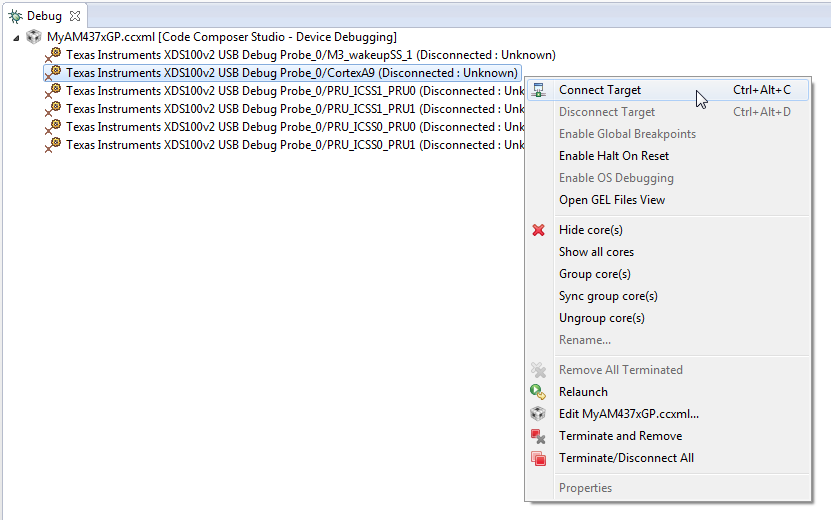

After launch, you can connect to a core. For GP AM437x EVM, select Cortex A9 and select “Connect Target”:

10.2.1.1.2.4.8. Success!¶

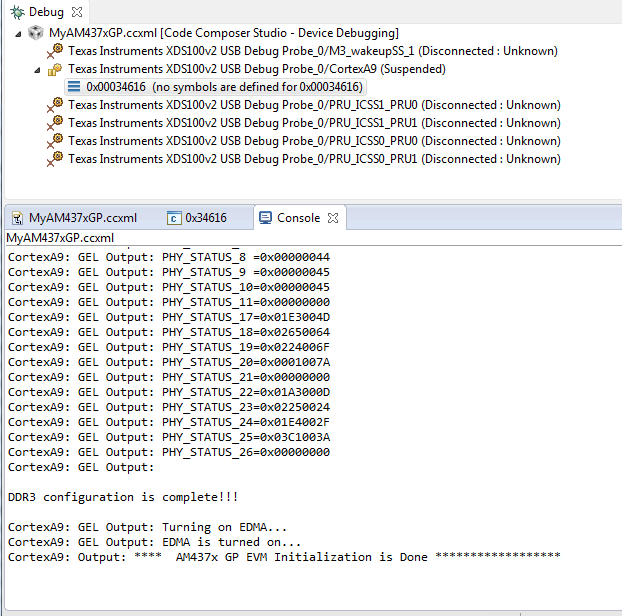

After connecting to target, check the console for status. Typically, the end of the configuration will indicate success or failure. For GP AM437x EVM, you will see the message “AM437x GP EVM Initialization is Done”:

10.2.1.1.2.5. Additional Notes for AM57x¶

10.2.1.1.2.5.1. Connect to AM57x Slave Cores¶

After connecting to the boot master core – typically the ARM core – you may need to connect to a slave core in order to run code. Depending on your SOC, the slave core can be

- DSP C66x

- ARM M4

- PRUSS

- IVAHD

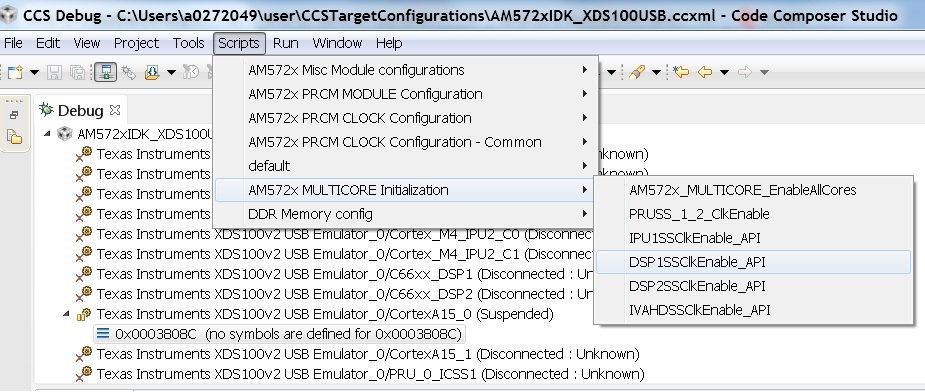

Typically the slave cores will wait in reset state until the master core

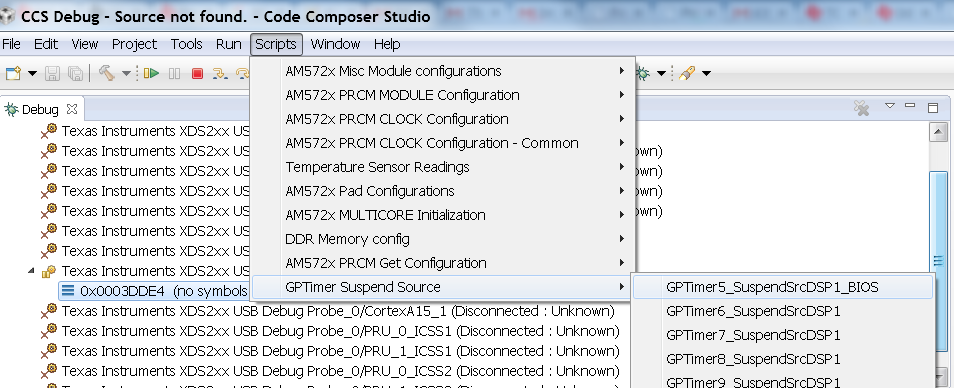

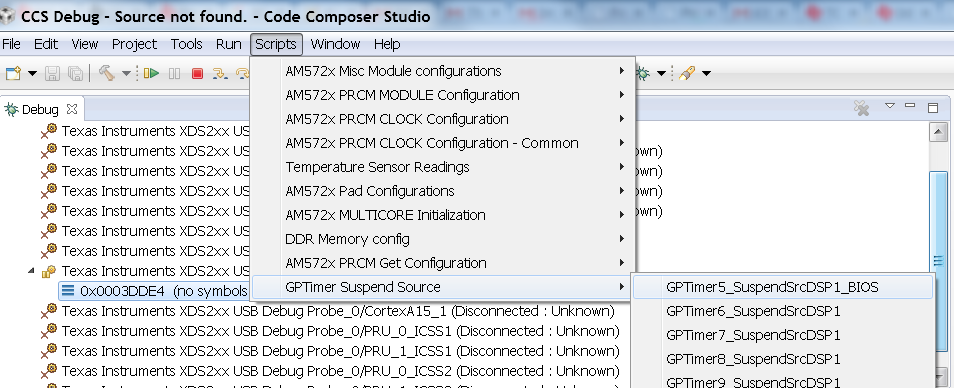

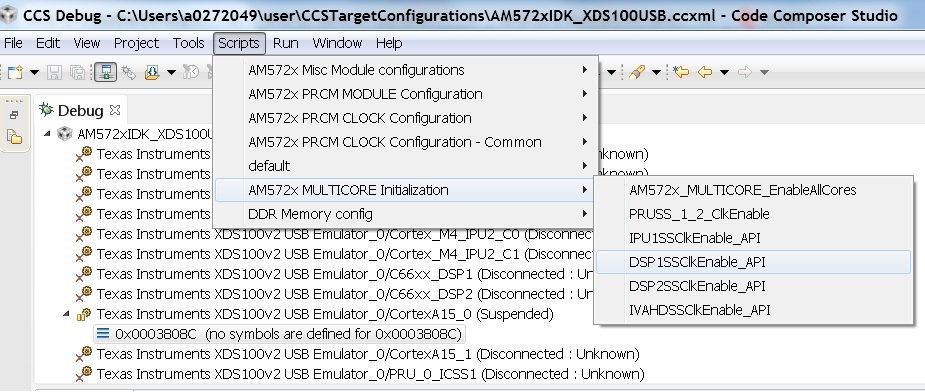

wakes up the slave core to run code. To connect to the slave core on

AM57x, go to Scripts menu in CCS Debug View and under AM572x

MULTICORE Initialization enable the corresponding sub system clock.

For example, enable DSP11SSClkEnable_API for the first DSP core.

After running the clock enable option, you can connect to the core.

10.2.1.1.2.5.2. Timer Suspend Control Options for DSP¶

On AM57xx devices, all the timers on the chip have their suspend control signal routed to the A15 core. Which means that if any of the slave cores are using these timers, the timers will continue to run even when the slave core has been paused. The timer will only pause when the A15 core is halted.

This is confusing while debugging code on slave cores if you are relying on timer for logging, inserting delays or if the timer keeps firing interrupts even when the core is halted. One such scenario occurs with GPtimer5 when DSP developers are using SYS/BIOS. The OS uses GPtimer5 on the DSP and forces a frequency check to confirm the timer configuration, however the OS can’t gain access to the timer due to the hook up of the suspend control signals.

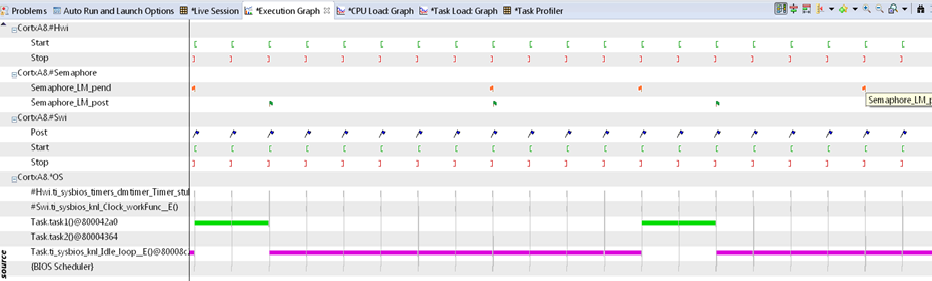

Due to this issue the SYS/BIOS developers will need to configure an additional CCS configuration check to connect the GPTimer suspend control signal to the DSP as shown in the image below:

10.2.1.1.2.6. Troubleshooting¶

If you face any problems, first check these basic items:

- Power cycle your target.

- Check the USB cable. One simple way to do this is to connect another device to the USB and ensure the cable works.

- Check host driver. Even with CCS turned off, your host should list the TI XDS as a USB device. If this does not work, try a different USB port.

- Latest emulation package. Ensure that you have the latest emulation files as specified in the Getting Started Guide.

If this does not resolve your problem, see these additional resources:

10.2.1.2. Update environment when installing to a custom path¶

10.2.1.2.1. Overview¶

This page will provide configuration information if the SDK is installed in a custom path.

Useful Tip

To avoid changing environment variable for each new shell, modify environment variable file directly. This file is the setupenv file located in the SDK root directory.

10.2.1.2.2. Changes to CCS Configuration¶

Installing the SDK in a folder other than where CCS is installed will require modifications to CCS to be able to discover the SDK. See the Setup CCS How To page explaining how to update CCS configuration.

10.2.1.2.3. Rebuilding the SDK RTOS¶

Installing the SDK in a folder other than the default (C:\TI for

Windows, /home/[user]/ti for Linux) requires modifications to SDK

RTOS scripts in order for recompilation and example/test creation to

work properly.

In all the commands below, replace [version] with the appropriate version of the software/tool.

10.2.1.2.3.1. CCS in Custom Path and SDK RTOS in Default Path¶

CCS installation and toolchain paths can be customized by setting the TOOLS_INSTALL_PATH environment variable prior to running the SDK level setupenv script. This feature is used if CCS and the toolchains are installed somewhere other than the default C:\ti location.

For example, environment configuration assuming CCS is installed to [os_base]\ti_temp and SDK RTOS has been installed to default path, [os_base]\ti :

- Windows

C:\> set TOOLS_INSTALL_PATH=C:\ti_temp

C:\> cd C:\ti\processor_sdk_rtos_[soc]_[version]

C:\ti\processor_sdk_rtos_[soc]_[version]> setupenv.bat

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: set CG_XML_BIN_INSTALL_PATH=C:/ti/cg_xml/bin

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: set DOXYGEN_INSTALL_PATH=C:/ti/Doxygen/doxygen/1.5.1-p1/bin

**************************************************************************

Environment Configuration:

PDK Directory : /ti/PDK_AM~3/packages/

CGTOOL INSTALL Directory : C:/ti_temp/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : C:/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : C:/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : C:/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : C:/ti_temp/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : C:/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : C:/ti/xdctools_[version]_core

BIOS_INSTALL_PATH : C:/ti/bios_[version]

IPC_INSTALL_PATH : C:/ti/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : C:/ti/edma3_lld_[version]

NDK_INSTALL_PATH : C:/ti/ndk_[version]

IMGLIB_INSTALL_PATH : C:/ti/imglib_c66x_[version]

UIA_INSTALL_PATH : C:/ti/uia_[version]

PROC_SDK_INSTALL_PATH : C:/ti/processor_sdk_rtos_[soc]_[version]

**************************************************************************

Changing to short name to support directory names containing spaces

current directory: C:/ti/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

**************************************************************************

- Linux

$ export TOOLS_INSTALL_PATH=~/ti_temp

$ cd ~/ti/processor_sdk_rtos_[soc]_[version]/

~/ti/processor_sdk_rtos_[soc]_[version]$ source setupenv.sh

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: export CG_XML_BIN_INSTALL_PATH="~/ti/cg_xml/bin"

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: export DOXYGEN_INSTALL_PATH="~/ti/Doxygen/doxygen/1.5.1-p1/bin"

**************************************************************************

Environment Configuration:

PDK Directory : /home/[user]/ti/pdk_[soc]_[version]/packages

CGTOOL INSTALL Directory : /home/[user]/ti_temp/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : /home/[user]/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : /home/[user]/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : /home/[user]/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : /home/[user]/ti_temp/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : /home/[user]/ti_temp/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : /home/[user]/ti/xdctools_[version]_core

BIOS_INSTALL_PATH : /home/[user]/ti/bios_[version]

IPC_INSTALL_PATH : /home/[user]/ti/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : /home/[user]/ti/edma3_lld_[version]

NDK_INSTALL_PATH : /home/[user]/ti/ndk_[version]

IMGLIB_INSTALL_PATH : /home/[user]/ti/imglib_c66x_[version]

UIA_INSTALL_PATH : /home/[user]/ti/uia_[version]

PROC_SDK_INSTALL_PATH : /home/[user]/ti/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

*******************************************************************************

The RTOS SDK top level Makefile can now be used to rebuild SDK RTOS components with CCS and toolchains installed in a custom installation path.

10.2.1.2.3.2. CCS in Default Path and SDK RTOS in Custom Path¶

SDK RTOS component installation paths can be customized by setting the

SDK_INSTALL_PATH variable prior to running the SDK level setupenv

script. This feature is used if the SDK is installed somewhere other

than the default C:\ti location.

For example, environment configuration assuming CCS is installed to the

default path, [os_base]\ti and SDK RTOS has been installed to

[os_base]\ti_temp:

- Windows

C:\> set SDK_INSTALL_PATH=C:/ti_temp

C:\> cd C:\ti_temp\processor_sdk_rtos_[soc]_[version]

C:\ti_temp\processor_sdk_rtos_[soc]_[version]> setupenv.bat

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: set CG_XML_BIN_INSTALL_PATH=C:/ti/cg_xml/bin

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: set DOXYGEN_INSTALL_PATH=C:/ti/Doxygen/doxygen/1.5.1-p1/bin

**************************************************************************

Environment Configuration:

PDK Directory : /ti_temp/PDK_AM~3/packages/

CGTOOL INSTALL Directory : C:/ti/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : C:/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : C:/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : C:/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : C:/ti/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : C:/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : C:/ti_temp/xdctools_[version]_core

BIOS_INSTALL_PATH : C:/ti_temp/bios_[version]

IPC_INSTALL_PATH : C:/ti_temp/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : C:/ti_temp/edma3_lld_[version]

NDK_INSTALL_PATH : C:/ti_temp/ndk_[version]

IMGLIB_INSTALL_PATH : C:/ti_temp/imglib_c66x_[version]

UIA_INSTALL_PATH : C:/ti_temp/uia_[version]

PROC_SDK_INSTALL_PATH : C:/ti_temp/processor_sdk_rtos_[soc]_[version]

**************************************************************************

Changing to short name to support directory names containing spaces

current directory: C:/ti_temp/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

**************************************************************************

- Linux

$ export SDK_INSTALL_PATH=~/ti_temp

$ cd ~/ti_temp/processor_sdk_rtos_[soc]_[version]/

~/ti_temp/processor_sdk_rtos_[soc]_[version]$ source setupenv.sh

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: export CG_XML_BIN_INSTALL_PATH="~/ti/cg_xml/bin"

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: export DOXYGEN_INSTALL_PATH="~/ti/Doxygen/doxygen/1.5.1-p1/bin"

**************************************************************************

Environment Configuration:

PDK Directory : /home/[user]/ti_temp/pdk_[soc]_[version]/packages

CGTOOL INSTALL Directory : /home/[user]/ti/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : /home/[user]/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : /home/[user]/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : /home/[user]/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : /home/[user]/ti/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : /home/[user]/ti/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : /home/[user]/ti_temp/xdctools_[version]_core

BIOS_INSTALL_PATH : /home/[user]/ti_temp/bios_[version]

IPC_INSTALL_PATH : /home/[user]/ti_temp/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : /home/[user]/ti_temp/edma3_lld_[version]

NDK_INSTALL_PATH : /home/[user]/ti_temp/ndk_[version]

IMGLIB_INSTALL_PATH : /home/[user]/ti_temp/imglib_c66x_[version]

UIA_INSTALL_PATH : /home/[user]/ti_temp/uia_[version]

PROC_SDK_INSTALL_PATH : /home/[user]/ti_temp/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

*******************************************************************************

The RTOS SDK top level Makefile can now be used to rebuild SDK RTOS components installed in the custom installation path.

Note

The following known issue impacts this step: PRSDK-1263: PDK AM437x: Make fails on Windows if CCS is installed in custom path. Workaround: Edit the UTILS_INSTALL_DIR variable in <pdk_root_dir>/packages/ti/starterware/Rules.make to point to the CCS installation on your Windows PC.

10.2.1.2.3.3. CCS and SDK RTOS in Custom Path¶

When CCS and the SDK RTOS are both installed to custom paths the SDK can be rebuilt by setting the SDK_INSTALL_PATH and TOOLS_INSTALL_PATH variables prior to running the SDK RTOS top level environment setup script. The Windows and Linux environment setup scripts can be found in the following locations, respectively:

- Windows - C:\custom\install\path\processor_sdk_rtos_[soc]_[version]\setupenv.bat

- Linux - /home/[user]/custom/install/path/processor_sdk_rtos_[soc]_[version]/setupenv.sh

The SDK_INSTALL_PATH and TOOLS_INSTALL_PATH environment variables must be set to the custom install path prior to running the environment setup script.

For example, environment configuration assuming CCS and the SDK have been installed to [os_base]\new_sdk_release\ :

- Windows

C:\> set SDK_INSTALL_PATH=C:\new_sdk_release

C:\> set TOOLS_INSTALL_PATH=C:\new_sdk_release

C:\> cd C:\new_sdk_release\processor_sdk_rtos_[soc]_[version]

C:\new_sdk_release\processor_sdk_rtos_[soc]_[version]> setupenv.bat

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: set CG_XML_BIN_INSTALL_PATH=C:/ti/cg_xml/bin

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: set DOXYGEN_INSTALL_PATH=C:/ti/Doxygen/doxygen/1.5.1-p1/bin

**************************************************************************

Environment Configuration:

PDK Directory : /NEW_SD~1/PDK_AM~1/packages/

CGTOOL INSTALL Directory : C:/new_sdk_release/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : C:/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : C:/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : C:/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : C:/new_sdk_release/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : C:/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : C:/new_sdk_release/xdctools_[version]_core

BIOS_INSTALL_PATH : C:/new_sdk_release/bios_[version]

IPC_INSTALL_PATH : C:/new_sdk_release/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : C:/new_sdk_release/edma3_lld_[version]

NDK_INSTALL_PATH : C:/new_sdk_release/ndk_[version]

IMGLIB_INSTALL_PATH : C:/new_sdk_release/imglib_c66x_[version]

UIA_INSTALL_PATH : C:/new_sdk_release/uia_[version]

PROC_SDK_INSTALL_PATH : C:/new_sdk_release/processor_sdk_rtos_[soc]_[version]

**************************************************************************

Changing to short name to support directory names containing spaces

current directory: C:/new_sdk_release/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

**************************************************************************

- Linux

$ export SDK_INSTALL_PATH=~/new_sdk_release

$ export TOOLS_INSTALL_PATH=~/new_sdk_release

$ cd ~/new_sdk_release/processor_sdk_rtos_[soc]_[version]/

~/new_sdk_release/processor_sdk_rtos_[soc]_[version]$ source setupenv.sh

Gives the output:

Optional parameter not configured : CG_XML_BIN_INSTALL_PATH

REQUIRED for xdc release build

Example: export CG_XML_BIN_INSTALL_PATH="~/ti/cg_xml/bin"

Optional parameter not configured : DOXYGEN_INSTALL_PATH

REQUIRED for xdc release build

Example: export DOXYGEN_INSTALL_PATH="~/ti/Doxygen/doxygen/1.5.1-p1/bin"

**************************************************************************

Environment Configuration:

PDK Directory : /home/[user]/new_sdk_release/pdk_[soc]_[version]/packages

CGTOOL INSTALL Directory : /home/[user]/new_sdk_release/ccsv6/tools/compiler/ti-cgt-c6000_[version]

TOOLCHAIN A15 Directory : /home/[user]/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A8 Directory : /home/[user]/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN A9 Directory : /home/[user]/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]

TOOLCHAIN M4 Directory : /home/[user]/new_sdk_release/ccsv6/tools/compiler/ti-cgt-arm_[version]

FPULIB_PATH : /home/[user]/new_sdk_release/ccsv6/tools/compiler/gcc-arm-none-eabi-[version]/lib/gcc/arm-none-eabi/[version]/fpu

CROSS_TOOL_PRFX : arm-none-eabi-

XDC_INSTALL_PATH : /home/[user]/new_sdk_release/xdctools_[version]_core

BIOS_INSTALL_PATH : /home/[user]/new_sdk_release/bios_[version]

IPC_INSTALL_PATH : /home/[user]/new_sdk_release/ipc_[version]

EDMA3LLD_BIOS6_INSTALLDIR : /home/[user]/new_sdk_release/edma3_lld_[version]

NDK_INSTALL_PATH : /home/[user]/new_sdk_release/ndk_[version]

IMGLIB_INSTALL_PATH : /home/[user]/new_sdk_release/imglib_c66x_[version]

UIA_INSTALL_PATH : /home/[user]/new_sdk_release/uia_[version]

PROC_SDK_INSTALL_PATH : /home/[user]/new_sdk_release/processor_sdk_rtos_[soc]_[version]

PROCESSOR SDK BUILD ENVIRONMENT CONFIGURED

*******************************************************************************

The RTOS SDK top level Makefile can now be used to rebuild SDK RTOS components installed in the custom installation path using CCS and toolchains installed in a custom path as well.

10.2.1.2.4. Rebuilding the PDK¶

Installing the PDK in a folder other than the default (C:TI for Windows, /home/[user]/ti for Linux) requires modifications to PDK scripts in order for recompilation and example/test creation to work properly.

10.2.1.2.4.1. CCS in Custom Path and PDK in Default Path¶

The instructions provided in the CCS in Custom Path and SDK RTOS in Default Path section can be used to rebuild components at the PDK level. The only difference is the PDK level setup script should be used instead of the SDK RTOS level setup script. The PDK level setup scripts are found in the following locations on Windows and Linux, respectively:

- Windows - C:\custom\install\path\pdk_[soc]_[version]\packages\pdksetupenv.bat

- Linux - /home/[user]/custom/install/path/pdk_[soc]_[version]/packages/pdksetupenv.sh

10.2.1.2.4.2. CCS in Default Path and PDK in Custom Path¶

The instructions provided in the CCS in Default Path and SDK RTOS in Custom Path section can be used to rebuild components at the PDK level. The only difference is the PDK level setup script should be used instead of the SDK RTOS level setup script. The PDK level setup scripts are found in the following locations on Windows and Linux, respectively:

- Windows - C:\custom\install\path\pdk_[soc]_[version]\packages\pdksetupenv.bat

- Linux - /home/[user]/custom/install/path/pdk_[soc]_[version]/packages/pdksetupenv.sh

10.2.1.2.4.3. CCS and PDK in Custom Path¶

The instructions provided in the CCS and SDK RTOS in Custom Path section can be used to rebuild components at the PDK level. The only difference is the PDK level setup script should be used instead of the SDK RTOS level setup script. The PDK level setup scripts are found in the following locations on Windows and Linux, respectively:

- Windows - C:\custom\install\path\pdk_[soc]_[version]\packages\pdksetupenv.bat

- Linux - /home/[user]/custom/install/path/pdk_[soc]_[version]/packages/pdksetupenv.sh

10.2.1.2.5. Creating PDK Example/Test Projects When CCS is Installed to Custom Path¶

The pdkProjectCreate scripts must be modified in order to build PDK example and test projects only if CCS has been installed to a custom path. The modification is the same for both Windows and Linux. Inside the pdkProjectCreate scripts is a CCS_INSTALL_PATH variable which points to the Code Composer Studio root directory. This variable must be redefined to the new location of the CCS root directory if CCS is installed to a custom path.

- Windows

REM Install Location for CCS

set CCS_INSTALL_PATH="C:\ti\ccsv6"

- Linux

# Install Location for CCS

export CCS_INSTALL_PATH=~/ti/ccsv6

Note

Prior to invoking the pdkProjectCreate script, make sure to start CCS and register the SDK RTOS components installed. Project creation will fail if the RTOS SDK components installed to the custom path have not been registered with CCS. Please see CCS and SDK installed in different directories for instructions on how to register SDK RTOS components installed to a custom path with CCS

10.2.1.3. Prevent BeagleBone board reset on JTAG Connect¶

https://elinux.org/Beagleboard:BeagleBone#Board_Reset_on_JTAG_Connect.28A3.2CA4.2CA5.29

10.2.1.4. Rebuild drivers from PDK directory¶

Refer Rebuilding the PDK for details on rebuilding the PDK components.

10.2.2. TI RTOS Basics¶

10.2.2.1. TI RTOS Tips & Tricks¶

10.2.2.1.1. Description¶

The intent of this article is to address common issues that TI RTOS users may run into while configuring SYSBIOS, XDCTools or working with RTSC packages in general on DSP and ARM devices. This is meant to provide insight into build and configuration issue nd must be used as an addendum document by Processor SDK USer to the SYSBIOS FAQs and XDCtools/RTSC documentation and TI RTOS Training

10.2.2.1.2. RTSC Diagnostics: Understanding XDC build errors¶

Some of the commonly observed XDC errors have been shown below. We try to explain how to understand and take corrective action.

10.2.2.1.2.1. xdc.tools.configuro: can’t locate the package ‘Package Name’ along the path: ...¶

This indicates that one of the packages that you linked in your BIOS configuration, can`t be located under XDCPATH. The XDC tools uses XDC paths like library search path, so if you run into this issue check that all the component packages have been added to XDCPATH and there is no typo or non-existent paths that you have added to this variable. TI RTSC packages usually have the name ti.<package name>. The packages are named to also sometimes helps locate the package inside the component. For example ‘’‘ti.platforms.evmAM335x’‘’ is located under BIOS_INSTALL_PATH/packages/’‘’ti/platforms/evmAM335x’‘’

For example if you are using packages from PDK (SOC driver packages)and BIOS (TI RTOS kernel), IPC (Interprocessor Communication) and NDK (Network development kit) then your XDCPATH needs to have following:

- BIOS_INSTALL_PATH/packages

- PDK_INSTALL_PATH/packages

- IPC_INSTALL_PATH/packages

- NDK_INSTALL_PATH/packages

10.2.2.1.2.2. xdc.cfg.SourceDir : Build of generated source libraries failed: exit status = 2:¶

A couple of different reasons could trigger this type of error

- Make sure there are no whitespaces or non-ASCII characters in any paths referenced by the build tools. In other words, make sure all software packages are installed in paths without spaces, and workspace and project names also do not have spaces or non-ASCII characters. We use gmake to build makefiles, and gmake doesn’t deal well with spaces in directory and file names.

- Take a close look at the CCS build console and ensure that the sh.exe used for the build is the one from the CCS directory. Also check your system PATH variable and see if there is another sh.exe (or gmake.exe) in your system PATH earlier than the one from the CCS installation. If there is one, then that will be used for the build and could cause build errors such as this. Some toolchains that are known to include sh.exe and could cause a conflict are Cygwin, WinAVR, Yagarto. In this case, remove those conflicting tools from the system PATH or modify the PATH so that the sh.exe and gmake.exe from CCS are seen first.

- Another source of problems related to sh.exe runnig Windows 10 may be Windows Defender. In “Windows Defender Security Centre”, “App and browser control”, “Exploit protection settings” one can add exceptions under “Program settings”. Adding a rule for “sh.exe” to disable/override “Force randomisation for images (Mandatory ASLR)”, “Randomise memory allocations (Bottom-up ASLR)”, “Validate stack integrity (StackPivot)”.

10.2.2.1.2.3. xdc.tools.configuro: missing input config script¶

The XDCtools build command should normally have the configuration script (.cfg file) passed at the end of the command. If the .cfg is not getting passed correctly, then this message will appear in the CCS build console. This error will then result in other compiler errors further down in the build.

You can confirm if the root cause is the .cfg file not getting passed correctly by looking at the subdir_rules.mk file in the directory Debug (or Release) in your project. The command line that runs configuro usually looks like this: <br>

"C:/ti/xdctools_3_xx_xx_xx/xs" --xdcpath="..." xdc.tools.configuro -o configPkg -t ti.targets.elf.C674 -p ti.platforms.evm6747

-r release -c "C:/ti/ccsv5/tools/compiler/c6000_x.x.x" --compileOptions "-g --optimize_with_debug" "$<"

10.2.2.1.2.4. Schema files not found¶

Usually after creating a RTSC package, developers are supposed to run xdc release to generate the package that contains the .sch files but if you accidentally delete the package or the developers requires xdc release to be run in user environment, you can run into this issue. This issue can be resolved by adding XDCtools to your environment PATH variable and running the command xdc release

set PATH=$PATH;<XDC_INSTALL_PATH>

xdc release

Detailed list of ‘’‘XDC Error codes’‘’ and Troubleshoot can be found here:

10.2.2.1.3. TI RTOS Platform configuration¶

10.2.2.1.3.1. Where does TI RTOS application get the Platform definition and memory sections on the SOC¶

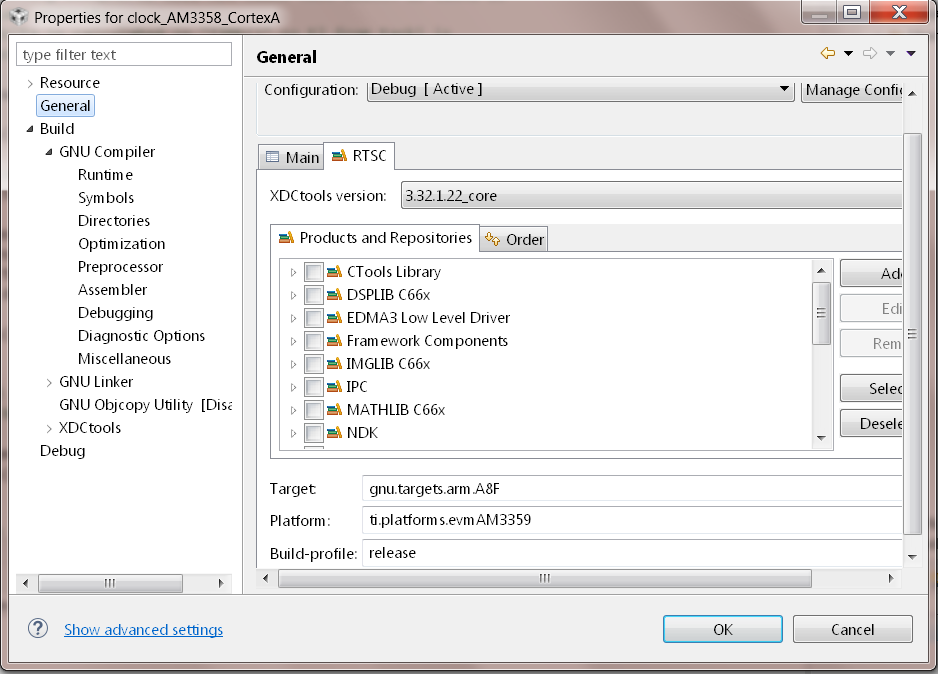

When creating a TI RTOS project, the user is required to specify the Platform and target core as part of their RTSC setup as shown below. This shows an example that is created for evmAM335x platform.

Selection of the platform essentially tell the build tools that the platform defintion should be picked up from the platform for evmAM335x from the directory path bios_x_xx_xx_xxpackagestiplatformsevmAM3359. If you open the Platform.xdc file under the folder path, you can see the default settings provided for this platform. This file combines the baseline AM335x SOC definition under bios_x_xx_xx_xxpackagesticatalogarmcortexa with the board specific setting like clockrate, DDR memory range.

10.2.2.1.3.2. How to create custom platform like DDRless platforms to use with TI RTOS projects¶

At some point in the application development process, most customers build their own boards, choosing a TI device and adding custom external memory. You will also need to create your own platform if any of the following items are true: * You want to customize cache sizes. * You want to manually override the default section placement. * You want application to run from on chip device memory.

For such custom boards you will need to create a platform using the platform wizard. The platform wizard is a GUI tool that allows you to easily create a custom platform. Creating a custom platform gives you a lot of flexibility in terms of defining the memory map and selecting default memory segments for section placement. This has been described in detail in following User guides and training links:

10.2.2.1.3.3. How to place code and data sections in different memory location than set by default TI RTOS platform configuration¶

User can place specific code and data sections in desired location by using the following syntax in the configuration (.cfg)

Program.sectMap[".data"] = new Program.SectionSpec();

/* Set the load address for .data section */

Program.sectMap[".data"].loadAddress = 0x82000000;

/* Set the run address for .data section */

Program.sectMap[".data"].runAddress = 0x82010000;

10.2.2.1.4. Generic TI RTOS questions¶

10.2.2.1.4.1. What is relationship between TI RTOS and XDCtools and RTSC¶

SYSBIOS uses underlying technology provided by Real Time Software Components (RTSC). * RTSC is an open-source specification within the Eclipse.org ecosystem for providing reusable software components (called “packages”) for use in embedded systems. * XDCtools is the actual product that contains all the tools necessary for you to use the SYS/BIOS components and configure your application. XDCtools is installed as part of Code Composer Studio (CCS). XDCtools is a separate software component provided by Texas Instruments that provides the underlying tooling needed for configuring and building SYS/BIOS, NDK, and UIA.

RTSC and XDCtools are important to SYS/BIOS users because:

SYS/BIOS_as_a_set_of_RTSC_packages containing the modules that make up the RTOS.

XDCtools provides configuration tools you use to create and build a static configuration as part of your application. This *.cfg configuration file specifies:

- Which modules from XDCtools, SYS/BIOS, and other components to include in the run-time image.

- What static instances of RTOS objects to create. For example, these include tasks and semaphores.

- Settings for parameter values for modules and objects.

XDCtools provides critical APIs that are used by SYS/BIOS and other related software components. These include memory allocation, logging, and system control.

The RTSC-pedia web site describes RTSC and XDCtools in more detail. In particular, it provides information for developers planning to create RTSC packages. It is also useful if you plan to edit configuration scripts with a text editor rather than using the XGCONF graphical editor provided withing CCS.

10.2.2.1.4.2. Can you use any SYSBIOS version with any version of XDCTools when creating create or migrating to TI RTOS based application development environment¶

This is a frequent issue for new user of TI RTOS. SYSBIOS releases are usually validated with a specific version of XDCTools that is described in the Release notes. It is generally not recommended to mix and match SYSBIOS versions with older or newer than the versions described as you may run into incompatibility issues. TI simplifies this build environments by packaging the TI RTOS package with XDCtools or by providing SDKs with the compatible versions of SYSBIOS kernel and XDCtools.

For customers using TI DSP and ARM Processors, it is recommended to use Processor SDK RTOS for TI RTOS development and to setup the CCS environment such its Preferences are set to use the versions included in the SDK. This process has been described: Processor_SDK_RTOS_Setup_CCS

10.2.2.1.4.3. Using SYSBIOS with GNU GCC (for ARM devices only)¶

The key care about of using SYSBIOS kernel on ARM based devices with GNU GCC compiler have been described in the article SYS/BIOS_with_GCC_(CortexA)

This wiki answers important questions about using SYSBIOS kernel with GNU GCC compiler like: * Changing entry point to an application

10.2.2.1.4.4. How do I port existing application developed on SYSBIOS application to SMP/BIOS¶

SYSBIOS supports SMP mode of operation on multi-core ARM and few dual core M3/M4 (IPU) subsytem present in Keystone and Sitara processors.

Training Slides: SMP SYSBIOS Overview presentation.

To Porting existing SYS/BIOS applications to SMP/BIOS, you can use the follow steps described below: * Merge existing separate applications into a single application. * Merge separate platform memory definitions as necessary. * Add this to your existing application’s config script:

BIOS.smpEnabled = true;

- Use these SMP-aware clone modules in place of their xdc.runtime equivalents for SysMin, SysStd, LoggerBuf (in ti.sybios.smp package)

‘’‘Note:’‘’ The existing Load module has been tweaked to provide minimal support for SMP. * For initial sanity testing, force all tasks to run on core 0:

Task.defaultAffinity = 0;

- Once basic functionality of the merged applications has been demonstrated, either remove Task.defaultAffinity setting or replace it with

Task.defaultAffinity = Task.AFFINITY_NONE;

The above statement will guide RTOS kernel to deploy tasks based on availability in the cluster of compute cores processing in SMP mode.

10.2.2.1.4.5. Are there any Graphical tools to configure SYSBIOS configuration¶

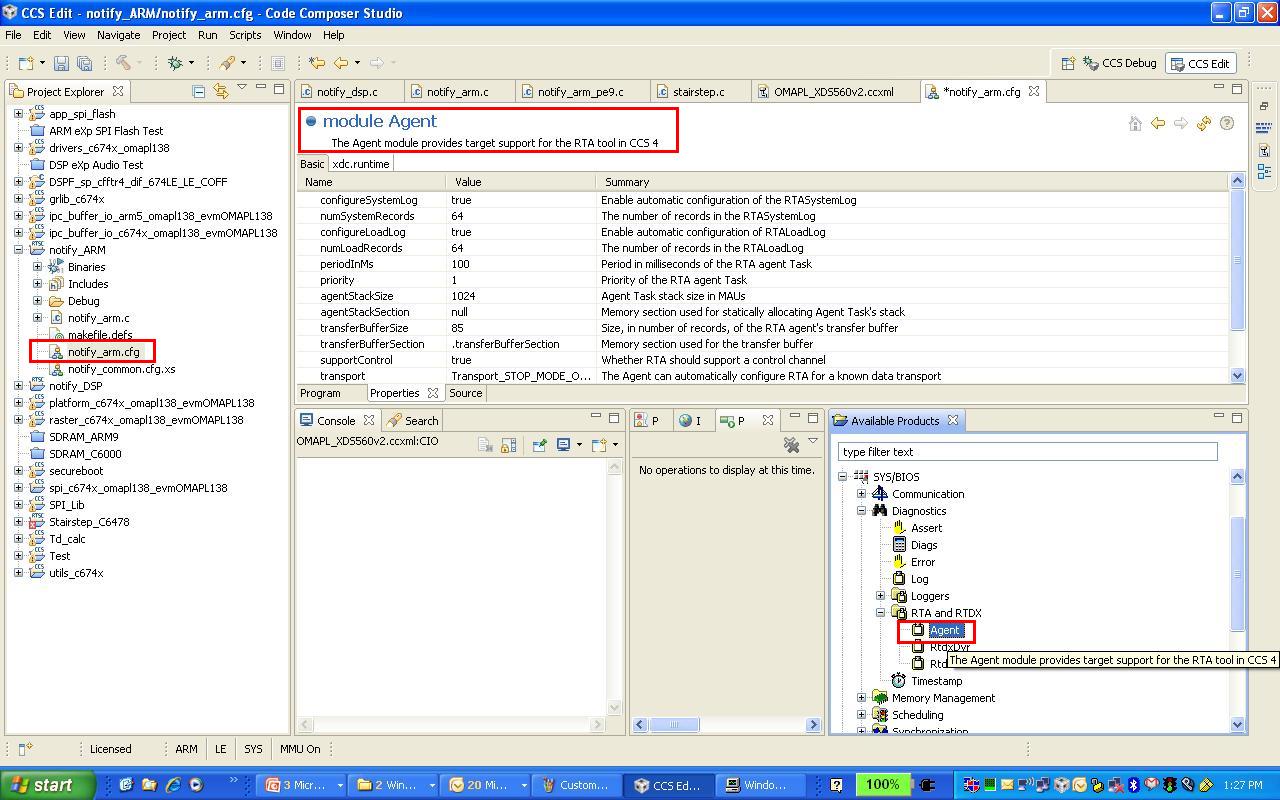

The easiest way for new users to add/configure new modules in the TI RTOS BIOS configuration is to use XGCONF based graphical tool

10.2.2.1.5. Thread Types¶

10.2.2.1.5.1. What is the difference between SWIs and Tasks¶

- A Swi is a non-blocking thread that runs to completion and can only be pre-empted by a higher priority Swi or a Hwi (interrupt). Swi’s can pre-empt a Task thread when posted and run on the ISR (system) stack (i.e. they do not have their own stack).

- A Task thread on the other hand is a blocking thread and can be pre-empted by a higher priority Task or by Swi/Hwi. A task usually has a while loop that keeps the task executing continuously in the system as long as it is required in the application. Also, Tasks run on their own independent stack.

10.2.2.1.5.2. How to add house keeping functions in the idle Task¶

If you want to use the idle time of the system to do some “housekeeping” jobs in the background, when the system is not active on interrupts or tasks, TI RTOS provides option to provide a task list or point to a housekeeping function which will run when no other thread is active in the system. The simplest syntax to add this to your code is shown below:

Task.enableIdleTask = true;

var Idle = xdc.useModule('ti.sysbios.knl.Idle');

Idle.addFunc('&osTaskIdleFunc');

If you open the BIOS configuration in XGCONF, you will notice that user are allowed to enter upto 8 function in the function list.

Syntax to add idle functions is provided below

var Idle = xdc.useModule('ti.sysbios.knl.Idle');

Idle.idleFxns[0] = "&myIdle1";

10.2.2.1.6. Hardware Interrupts (HWI)¶

10.2.2.1.6.1. How to configure Crossbar when setting up interrupts on DRA7xx/TDA2xx/AM57xx¶

Some socs like AM571x and AM572x have a large number of interrupts requests to service the needs of its many peripherals and subsystems. All of the interrupt lines from the subsystems are not needed at the same time, so they have to be muxed to the irq-controller appropriately. In such places a interrupt controllers are preceded by an CROSSBAR that provides flexibility in muxing the device requests to the controller inputs.

Application developers have two options to setup interrupts on AM57xx/TDA2xx/DRA7xx devices which provide a crossbar mechanism to connect a given IRQ source to an IRQ line on the target cpu’s interrupt controller. The device level chip support library provides functional APIs to map interrupt events to target core interrupt controller line.

For example SPI3_IRQ to the CROSSBAR input on DSP and M4, you can use the following:

DSP Core1 configuration of SPI3_IRQ to crossbar input 60:

/* Configure xbar connect for MCSPI3: DSP_IRQ_43 (reserved) mapped to MCSPI3 intr */

CSL_xbarIrqConfigure (CSL_XBAR_IRQ_CPU_ID_DSP1,

CSL_XBAR_INST_DSP1_IRQ_43, /* should match with C66 intc eventId used for event combiner that maps to DSP interrupts*/

CSL_XBAR_MCSPI3_IRQ);

IPU core1 configuration of SPI3_IRQ to crossbar input 43:

/* Configure xbar connect for MCSPI3: IPU1_IRQ_60 (reserved) mapped to MCSPI3 intr */

CSL_xbarIrqConfigure (CSL_XBAR_IRQ_CPU_ID_IPU1,

CSL_XBAR_INST_IPU1_IRQ_60, /* should match with M4 intNum used for HWI_create */

CSL_XBAR_MCSPI3_IRQ);

Here is how you would define the same interrupt handler for IPU statically in a configuration script:

var Hwi = xdc.useModule('ti.sysbios.family.arm.m3.Hwi');

var IntXbar = xdc.useModule('ti.sysbios.family.shared.vayu.IntXbar');

// Connect IRQ 23 to Interrupt source index 86 (SPI3_IRQ)

IntXbar.connectIRQMeta(60, 86);

// Alternately, the connectIRQMeta API can be used. This

// API expects XBAR instance number as an argument.

//

// Connect Xbar Instance 1 (IRQ 60) to Interrupt

// source index 86 (MCSPI3_IRQ)

//

// IntXbar.connectMeta(1, 60);

var hwiParams = new Hwi.Params();

hwiParams.arg = 60;

10.2.2.1.7. Clocks and Timers¶

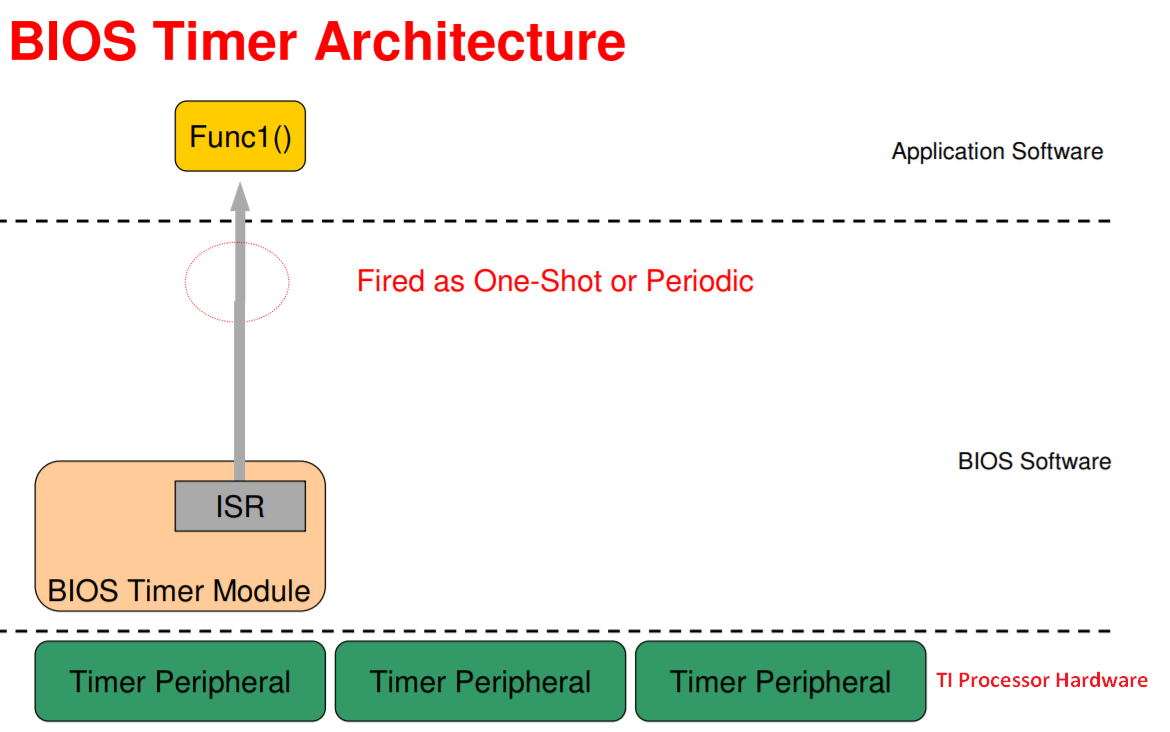

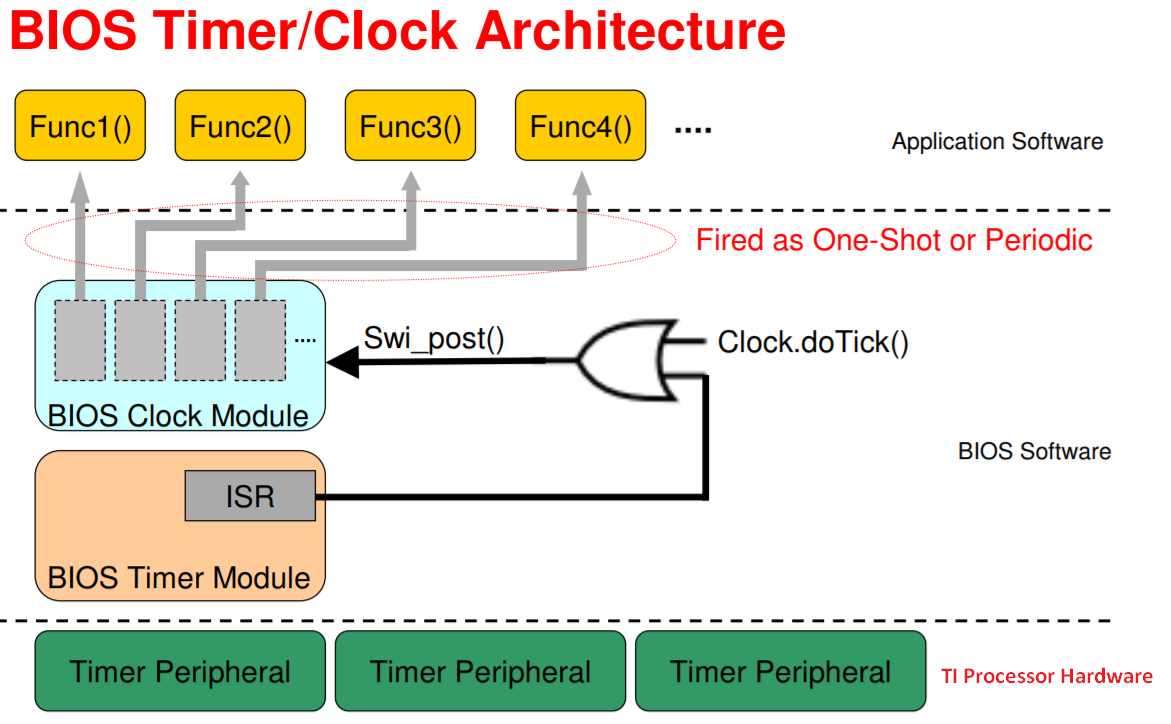

10.2.2.1.7.1. What are the different clock and timer modules in TI RTOS that you should be aware of?¶

- Timer Module

- Manages timer peripherals

- Provides target/device abstraction

- Clock Module

- Manages BIOS “heartbeat”

- Can schedule functions to fire in the future (one-shot or periodically)

- Input can be configured to use Timer module “tick” or application “tick”

- Timestamp Module

- Provides simple time stamping services for benchmarking code

- Allows time stamping RTA logs

BIOS Timer Architecture

BIOS Clock Architecture

10.2.2.1.7.2. How to get accurate clock ticks from the clock module?¶

The clock module uses the CPU clock setting that is provided by the default platform setting. For example, if the platform is set to AM335x, then the clock is assumed to be 550 MHz, so the clock ticks will be generated with period of 1.8 nanoseconds. ‘’‘TI RTOS doesn`t setup the device clocks, the device clock initiation is the responsibility of the initialization code’‘’ (GEL file in debug environment and bootloader in production environment)

After, the clocks are configured, it is the responsibility of the application developer to inform BIOS of the CPU frequency so that accurate system ticks can be generated.

Note: For example if the core clock on AM335x is set to 720 MHz instead of default 550 Mhz, then users are required to add the following like the .cfg to inform BIOS kernel of the actual CPU setting.

BIOS.cpuFreq.lo = 720000000;

We reiterate that this doesn`t change the actual frequency but only informs the OS of the change from default CPU freq setting.

10.2.2.1.7.3. How to set input frequency in SYSBIOS configuration and change timer used by clock module¶

Timer.intFreq[index] determines the input clock that drivers the timer. In most cases the input clock is assumed to be the input clock used in TI EVM (Example: 24 Mhz used on AM335x EVM). If you have a different input on your custom board users are required to change the input Freqency setting in their configuration. To change the dmtimer frequency in SYS/BIOS you need to add the following to your config file:

var Timer = xdc.useModule('ti.sysbios.timers.dmtimer.Timer');

Timer.intFreqs[index] = {hi: 0, lo: 19200000};

Where index is the SYS/BIOS timer ID. Please remember that timer IDs do not necessarily match the number in the peripheral name. For example on AM335x SYS/BIOS Timer 0 actually corresponds to DMTimer2 on the device. Use the Timer Mapping Table to determine which timer corresponds to each Timer ID.

The Clock module uses a Timer internally. By default, the Clock module calls Timer_create() with “ANY” which will return one of the available timers. You can specify the exact timer using the following (the default value for Clock.timerId is ANY).

To set it to a specic timer Id, you can use the following syntax.

Clock= xdc.useModule('ti.sysbios.knl.Clock');

Clock.timerId = 3;

10.2.2.1.8. SemiHosting¶

10.2.2.1.8.1. Why can`t I see output of System_printf on CCS console?¶

When getting started with TI RTOS, you may notice that the printf from your code goes to CCS console but using non-intrusive System_printf doesn`t. If you want to have System_printf output go to the same place as printf, add the following three lines to your .cfg file and re-build:

var System = xdc.useModule('xdc.runtime.System');

var SysStd = xdc.useModule('xdc.runtime.SysStd');

System.SupportProxy = SysStd;

If you don’t do this, the output will go to a circular buffer in memory. You can examine that buffer using the ROV tool (use the menu: Tools->ROV while in the debugger).

10.2.2.1.8.2. How to enable printf/System_printf to go to CCS IO console on ARM devices¶

Application developers need to add the SemiHosting module to the .cfg manually by editing the config script. Add the following line:

var SemiHostSupport = xdc.useModule('ti.sysbios.rts.gnu.SemiHostSupport');

This module does the required setup (install SVC_Handler and do the required file handle init) to support SemiHosting.