- Docs »

- 4. Foundational Components

-

4. Foundational Components

4.5. Boot

Overview

This page provides an overview about the Secondary Bootloader support

provided in Processor SDK RTOS.

The Secondary Bootloader (SBL) sets-up the PLL clocks, powers on the

I/O Peripherals, initializes the DDR, loads the application image into

DDR & brings the slave cores for applicable SOCs out of reset.

Additional details including execution boot flow is covered in more

elaborate detail under individual SOC section.

Boot Modes

MMCSD

MMCSD bootloader is required to boot target using an SD card containing

bootloader and application images. When the board is powered ON the ROM

bootloader detects the MMCSD bootloader image and loads it to the

internal memory.The bootloader initializes the board, copies the

application image from SD card to the DDR memory and gives control to

the application.

QSPI

A flash device interfaced with QSPI is flashed with QSPI bootloader and

application images. When the board is powered ON the ROM bootloader

detects the bootloader image from flash device and loads it to the

internal memory. The Bootloader initializes the board, copies the

application image from QSPI device to the DDR memory and gives control

to the application.

UART

A Serial connection is used for transferring the bootloader binary from

PC to target board through XMODEM protocol. The bootloader on execution

prompts for application image to transfer through XMODEM. On providing

the path, the application binary is transferred through serial

connection to DDR memory and the control is passed to application to

execute.

MCSPI/SPI

A SPI flash device flashed with MCSPI/SPI bootloader and application

images is used for booting the board. When the board is powered ON the

ROM bootloader detects the bootloader image from flash device and loads

it to the internal memory. The Bootloader initializes the board, copies

the application image from flash to the DDR memory and gives control to

the application.

NAND

NAND flash with bootloader and and application images is used for

booting the board. When the board is powered ON the ROM bootloader

detects the bootloader image from flash device and loads it to the

internal memory. The bootloader initializes the board, copies the

application image from flash to the DDR memory and gives control to the

application.

4.5.1. AM335x/AM437x

Overview

Bootloader supports power-on-reset bootstraps for the board. It

initializes board, loads application from the memory device to DDR and

transfers control to application. Section provides additional details

including flashing and booting instructions across different media.

Source Reference

< BASE_DIR = PDK_INSTALL_DIR\packages\ti\starterware>

Bootloader build files for AM335x/AM437x

Source files:

- BASE_DIRbootloadersrc: Common source files for bootloader

functionality

- BASE_DIRbootloadersrc<device>: Files specific to device to

initialize platform features like PLL, pinmux and DDR

Build Files:

- BASE_DIR/build/makerules/rules_a8.mk: Common Compiler flags used

for A8 cores. Applies to AMIC110 and AM335x

- BASE_DIR/build/makerules/rules_a8.mk: Common Compiler flags used

for A9 cores. Applies to AM437x devices

- BASE_DIR/build/makerules/platform.mk: Global settings for all

components for a particular platform.

- BASE_DIR/build/makerules/components.mk: Specific settings for

components in starterware

- BASE_DIR/build/makerules/build_cfg.mk: Flags to enable features

in the build

- BASE_DIR/bootloader/Makefile: Makefile for bootloader that

provides list of source files and library to create bootloader

binary.

Boot and flashing tools:

- BASE_DIR/tools Contains tools to create boot images and flashing

tools to program the boot binary on the boot media.

Bootloader execution sequence

The Processor SDK RTOS boot loader uses a two stage boot process. The

different stages of the application boot sequence using Processor SDK

RTOS bootloader are shown below:

Boot Sequence

- Power on Reset

- ROM Bootloader (RBL)

- Platform configuration and initialization.

- DPLL and clock settings for MPU, I2C, MMCSD, USB, SPI, QSPI,

Ethernet etc.

- Checks Sysboot pins and choose booting device

- If no valid bootloader found on booting device, RBL checks for

next booting device. The sequence depends on RBL execution flow

and Sysboot pins.

- RBL gets image size and load address by checking TI Image Header

appended on bootloader binary(.bin). Check binary

formats.

- Loads the binary to internal OCMC memory at the Load address

fetched from TI Image Header

- Passes control to Secondary Bootloader(SBL)

- Secondary Bootloader(SBL)

- Configure PLL and Initialize DDR

- Configure PRCM and PinMux for Boot Peripherals

- Copies application image to DDR

- Passes execution control to Application

- Application execution

Tools and Binary formats

| Binary format |

Requirement |

Details |

| .bin |

QSPI bootloader,

UART bootloader and

app

|

QSPI bootloader

binary should in .bin

format and

Application binary

should be in _ti.bin

format.

UART bootloader and

applications are

loaded in .bin format

through XMODEM in

terminal.

|

| _ti.bin |

MMCSD bootloader

and app,

NAND bootloader and

app,

MCSPI boot loader and

app,

QSPI app.

|

.bin binaries are

converted to

_ti.bin format by

adding Image

size(4bytes) and

Image load

address(4bytes) as

image header.

Refer to Image

format section in

Initialization

chapter of AM437x

TRM

MMCSD, NAND and MCSPI

boot loaders and

application binaries

should be appended

with ti image header.

|

TI Boot image

| Offset |

Binary value |

|---|

| 0x00000000 |

Size |

| 0x00000004 |

Entry Point (Location) |

| 0x00000008 |

Binary (.bin) |

NOTE

* For bootloader Entry point is usually 0x402f0000

- For the app the entry point is usually 0x80000000.

Binary format conversion procedure

Binary format conversion in Linux

- To convert from .out -> .bin

TOOLCHAIN_PATH_<A8/A9>/bin/arm-none-eabi-objcopy -O binary <application>.out <application>.bin

- Build tiimage.out. Go to starterware/tools/ti_image/

gcc tiimage.c –o tiimage.out

- To convert from .bin -> _ti.bin

tiimage.out <Image Load Address> NONE <application>.bin <application>_ti.bin

Binary format conversion in Windows

- To convert from .out -> .bin

TOOLCHAIN_PATH_<A8/A9>/bin/arm-none-eabi-objcopy -O binary <application>.out <application>.bin

2) To convert from .bin -> _ti.bin. tiimage.exe is provided as prebuilt

binary in starterware/tools/ti_image.

tiimage.exe <Image Load Address> NONE <application>.bin <application>_ti.bin

Boot Modes supported

Following are the Boot Modes supported through AM335x/AM437x bootloader

for the various EVMs.

| |

MMCSD |

NAND |

McSPI |

QSPI |

UART |

| AM335x

GPEVM |

YES |

YES |

YES |

NO |

YES |

| AM335x

ICEv2 |

YES |

NO |

YES |

NO |

NO |

| AM335x

StarterKi

t |

YES |

NO |

NO |

NO |

YES |

| AM335x

BeagleBon

eBlack |

YES |

NO |

NO |

NO |

YES |

| AM437x

GPEVM |

YES |

NO |

NO |

NO |

YES |

| AM437x

IDK |

YES |

NO |

NO |

YES |

NO |

| AM437x

StarterKi

t |

YES |

NO |

NO |

NO |

NO |

Building the Bootloader

- Pre-requisite: Setup SDK build environment as described in article

- Setup_Environment

Normal Operation of Bootloader:

Bootloading an application from flash into DDR memory as in case of TI

evaluation platforms is described as normal operation mode for the

bootloader. This is the default behaviour of the bootloader and can be

built using the following command in starterware.

gmake bootloader BUILDCFG=boot BOOTMODE=<BOOT_MODE> PLATFORM=<EVM> PROFILE=<BUILD_PROFILE> -s KW_BUILD=no

- BOOT_MODE: mcspi, nand, qspi, mmcsd, uart (Check supported boot modes

for your evaluation platform)

- EVM: am335x-evm, am43xx-evm, amic110-ddrless

- BUILD_PROFILE: debug, release

Additional Build options (currently support only for

AMIC110/AM335x ICE Users)

- DDR less Application boot setup

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=amic110-ddrless PROFILE=debug -s KW_BUILD=no USE_DDR=no

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=amic110-ddrless PROFILE=release -s KW_BUILD=no USE_DDR=no

This option builds an ultra light weight (<10 KB) bootloader for cost

optimized application that don`t external DDR memory.

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=am335x-evm PROFILE=debug -s KW_BUILD=no ENABLE_PRU=yes

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=am335x-evm PROFILE=release -s KW_BUILD=no ENABLE_PRU=yes

This feature is required in application that need to quick wake up of

ICSS/PRU cores. The PRU cores can be woken up and loaded from the SBL by

combining the ENABLE_PRU and BIN_LOAD arguments.

- Load additional binaries from flash

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=am335x-evm PROFILE=debug -s KW_BUILD=no BIN_LOAD=yes

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=am335x-evm PROFILE=release -s KW_BUILD=no BIN_LOAD=yes

The location of binaries in offset is configured using

sbl_flash_offset_cfg.h in the bootloader source. Users are required to

use TIIMAGE tool to append an header to the binary so that the

bootloader knows the loction and size of the binary to be loaded.

Industrial DDRless Booting

The AMIC110 DDRLESS platform provides a superset flag to enable all the

above features and build the bootloader . The superset build is invoked

using BUILD_ICSS_DDRLESS_BOOT=yes as shown below:

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=amic110-ddrless PROFILE=debug -s KW_BUILD=no BUILD_ICSS_DDRLESS_BOOT=yes

gmake bootloader BUILDCFG=boot BOOTMODE=mcspi PLATFORM=amic110-ddrless PROFILE=release -s KW_BUILD=no BUILD_ICSS_DDRLESS_BOOT=yes

Prebuilt binaries inside the Processor SDK RTOS for AMIC110-DDRLESS will

be configured using this option to allow for testing of cost optimized

industrial use case.

Boot Mode settings

Boot mode settings for all supported AM335x and AM437x boards are

here

Boot Modes

Booting Via SD Card

Booting from SD Card involves two steps.

- Preparing SD card.

- Booting target.

Preparing SD card

- To boot target the SD card should be bootable. Follow the steps at

Creating bootable SD card in

windows

or Creating bootable SD card in

Linux.

- Delete the “MLO” and “app” in the bootable SD card which are

created in the process of making the SD bootable.

- Bootloader images with ti header (<mmcsd_bootloader>_ti.bin)should be

renamed to “MLO”. Bootloader images are located at

<PDK_INSTALL_DIRpackagestistarterwarestarterwarebinarybootloaderbin<TargetType>

- Similarly the converted application binary image has to be renamed to

“app” from “<app_name>_ti.bin“

- Copy both the boot loader image “MLO” and the application image

“app” to the SD card.

- The SD card is ready for use on target.

Booting target

- Insert SD card to the base board SD slot. Connect a UART cable to a

host running a serial terminal application (teraterm/hyperterminal)

with 115200 baud, 8bit, No parity and 1 STOP bit configuration.

- Configure the board for SD Boot mode

- SD instance 0 (on base board) is available in all profiles.

- SD instance 0 boot mode needs to appropriately set. For SD boot to

be selected first, SD boot should appear first in the boot device

list in the boot mode. If any other boot mode is selected, even if

a SD boot card is inserted, and does not appear first in the list,

the first available sane boot image (like NAND or SPI etc) is

booted and SD is not selected. Only if no sane boot image is found

in the first devices, SD boot image will be selected.

- Once SD boot image is chosen, the MLO is first detected and copied

and executed from the OCMC0 RAM. The MLO then copies the

application image (app) from the card to the SDRAM and passes the

control to the application. If the process is succesful, messages

identifying board and SoC will appear on the serial console.

After this the application will take control and execute.

NOTE: If board have BootMode selection pins choose proper Boot

Selection pins from hardware reference manuals.

If the boards have no boot mode selection pins and a valid boot image

is present on McSPI flash, Booting will happen from McSPI flash. Erase

McSPI flash in such cases to boot from SD card

McSPI flash

erase

. The boot sequence depends on ROM bootloader.

Booting Via QSPI

Booting from QSPI flash involves two steps-

- Preparing Flash Device

- Booting target.

Preparing Flash Device

Procedure relies on contents being copied to SD card. Additional

details below:

- Copy bootloader image(bootloader_boot_qspi_a9host_debug.bin rename)

and app image(“<app_name>_ti.bin”) into the SD card.

The file names have to be renamed in such a way that the length of

name is less than 9 characters. Any file name less than 9 characters

can be used.

Rename the bootloader file to ‘boot’ and application image to ‘app’

with no extensions.

- Copy the ‘config’ file into the SD card which will contain the names

of the image to be flashed and the offset.

A sample config file can be found at

<PDK_INSTALL_DIRpackagestistarterwarestarterwaretoolsqspiconfig>

directory. Do not change name of the config file.

NOTE: “config” file can be used without any modifications if

bootloader and application images are renamed to “boot” and “app”.

NOTE: Do not rename bootloader to be copied to SD card as

“MLO”, as MMCSD bootloader expects “MLO” and “app” to boot.

- Now SD card contains 1)boot 2)app 3)config files.

config file contains the address of boot image as 0x0 and app

image as 0x80000.

Insert it into the SD card slot.

- Connect the board with CCS and load the prebuilt qspi flash writer

application from

<PDK_INSTALL_DIRpackagestistarterwarestarterwarebinaryqspi_app_flash_writerbinm43xx-evm>

- Run the QSPI flash writer application. Following logs expected on

console.

StarterWare QSPI Flash Writer!!

BOARDInit status [0x0]

SoC : [AM43XX]

Core : [A9]

Board Detected : [IDKEVM]

Base Board Revision : [UNKNOWN]

Daughter Card Revision: [UNKNOWN]

Copying boot to QSPI Flash

Copying app to QSPI Flash

Changing read to quad mode

Read mode has been changed to Quad mode

SUCCESS!!!

Flashing completed

Booting the target.

- Connect UART cable to a host running serial terminal application

(teraterm/hyperterminal) with 115200 baud, 8bit, No parity and 1 STOP

bit configuration.

- After flashing successfully remove SD card and reboot to see

following logs

StarterWare Boot Loader

BOARDInit status [0x0]

SoC : [AM43XX]

Core : [A9]

Board Detected : [IDKEVM]

Base Board Revision : [UNKNOWN]

Daughter Card Revision: [UNKNOWN]

Copying Header of the application image

Copying image from flash to DDR

Jumping to StarterWare Application...

NOTE: Boot logs will appear approximately after 25 seconds on reset.

NOTE:If there is no boot mode selection present on board, boot image will be loaded depending on ROM boot sequence

Example: If QSPI flash and MMCSD has valid bootloaders, on reset MMCSD boot image will be loaded following ROM Boot sequence.

Booting Via UART

ROM and Bootloader supports XMODEM protocol with images being binary

not requiring any additional headers. Following are steps for boot:

- Configure board for UART boot mode :

UART boot need to be first in the boot device list. Note: In case if

any other boot mode is selected, the first available boot image

(eg:NAND or MMCSD etc) will override. In case of no valid images,

UART boot will be selected.

- Select View->Memory Browser through CCS.

- Select address 0x44e10040.

- Write 0x19 to last 2 bytes of this memory address.(UART boot)

- Soft reset the board. This is a volatile bit which gets reset

after power on.

- ROM code will print “CC..” on UART console expecting Bootloader via

XMODEM. File can be sent via xmodem through tera-term File-> Transfer

-> XMODEM -> Send.

- On transmitting bootloader

image, bootloader_boot_uart_a9host_debug.bin via XMODEM, following

message will be expected on serial console.

CCCCCCCCCCCCCCCCCCCCCCCCCCCC

StarterWare Boot Loader

BOARDInit status [0x0]

SoC : [AM43XX]

Core : [A9]

Board Detected : [IDKEVM]

Base Board Revision : [UNKNOWN]

Daughter Card Revision: [UNKNOWN]

GPIO Instance number: 0

Pin number: 22

Please transfer file:

CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC

4. As a next step application binary (without header) can be sent

via XMODEM which will lead to application start executing.

Booting Via McSPI

Booting from McSPI involves two steps.

- Preparing Flash Device

- Booting the target.

Preparing Flash Device

- Set the appropriate bootmode if applicable for EVM.Refer Boot mode

settings.

Note: Most of the boards may not have switch settings.

- Add a required target configuration in CCS depending on emulator and

board connected.

- Connect target to required core. Ex: A8.

- Load the flash writer from

<PDK_INSTALL_DIRpackagestistarterwarestarterwaretoolsflash_writerspi_flash_writer_AM335X.out

onto the EVM.

- Run the application and observe the logs on CCS console.

Starting SPIWriter.

Choose Operation:

Enter 1 ----> To FLASH an Image

Enter 2 ----> To ERASE Flash

Enter 3 ----> To EXIT

- When Flash option is chosen program prompts to enter file name.

- Provide the complete path of file

bootloader_boot_mcspi_a8host_release_ti.bin at directory

“binary/bootloader/bin/<PLATFORM>/<gcc/ccs>/” and hit Enter.

Enter the Offset in bytes (in HEX)

- Provide 0x00000 to flash bootloader.

- To flash application binary image <app_name>_a8host_ti.bin, provide

0x20000.

- Wait for few miniuits as flashing is a slower process.

Erasing flash at byte offset: xx, byte length: xxxx

SF: Successfully erased xxxx bytes @ xxxx

Writing flash at page offset: x, number of pages: xxxx

Flashing is in progress...

Verifying... Success.

- Once SPI flash writing completes disconnect target.

Booting the target

- Connect a serial cable to a host running a serial terminal

application (teraterm/hyperterminal) with 115200 baud, 8bit, No

parity and 1 STOP bit configuration.

- Configure the board for SPI boot mode.

- On reset, ROM bootloder copies the bootloader from flash to internal

memory. The bootloader then copies the application image from flash

to DDR and passes the control to the application.

Booting Via NAND

Booting from NAND involves two steps.

- Preparing Flash Device

- Booting the target.

Preparing Flash Device

- Configure BOOT pins for NAND Boot mode

settings

- Connect target with CCS.

- Load the

<PDK_INSTALL_DIRpackagestistarterwarestarterwaretoolsflash_writernand_flash_writer_AM335X.out>

to target and Run. Flash writer will output messages to CCS console.

When it prompts for inputs, proper inputs shall be given via CCS

console.

- When prompted for binary file name, update file with proper path.

- Select option for flashing.

Choose your operation

Enter 1 ---> To Flash an Image

Enter 2 ---> To ERASE the whole NAND

Enter 3 ---> To EXIT

- If Option 1 is selected, enter image path to flash when prompted as

shown below.

Provide the complete path (e.g.

<PDK_INSTALL_DIRpackagestistarterwarestarterwarebinarybootloaderbin<am335x/am437x-evm><compiler>bootloader_boot_nand_a8host_<debug/release>_ti.bin)

- Enter offset when prompted as shown below.

This offset is start location from where the image should be

flashed.

NOTE:

- Use hex format

- If bootloader is to be flashed, provide 0x00000. For application

binary, provide 0x80000.

Choose the ECC scheme from given options

Enter 1 ---> BCH 8 bit

Enter 2 ---> HAM

Enter 3 ---> T0 EXIT

Please enter ECC scheme type:

Always select BCH8 for bootloader and application as ROM code and

bootloader uses the BCH8 ECC scheme.

- Ensure that flash info displayed by tool matches NAND flash in EVM.

- After this tool should first erase the required region in flash and

then start flashing new image.

- If flashing procedure is complete following message should be

displayed.

Application is successfully flashed

NAND flashing successful!

- Once NAND flash writing completes, disconnect from CCS.

Booting the target

- Connect a UART cable to a host running a serial terminal application

(teraterm/hyperterminal) with 115200 baud, 8bit, No parity and 1 STOP

bit configuration.

- Configure the board for NAND boot mode. Refer Boot mode

settings

- On reset, ROM detects bootloader from NAND and copies it to internal

memory. Bootloader then copies application image from the NAND to DDR

and passes control to application. If the process is succesful,

following messages appear in serial console.

StarterWare Boot Loader

BOARDInit status [0x0]

SoC : [AM335X]

Core : [A8]

Board Detected : [GPEVM]

Base Board Revision : [1.5]

Daughter Card Revision: [UNKNOWN]

NAND flash is connected to GPMC on this board

Jumping to StarterWare Application...

After this application should take control and execute.

Test Application

The section explains steps for building and booting a sample pdk

application for am335x or am437x using MMCSD bootloader.

Test Application Image Creation

Follow below steps to generate the bootable application image.

- Generate .out files using steps for Rebuilding

PDK. Locate .out file in directory

<PDK_INSTALL_PATH/MyExampleProjects/<ExampleProjectDirectory>/Debug>

- Convert files to support MMCSD boot using steps as per Binary format

conversion

procedure.

- Rename generated <Application>_ti.bin to “app”.

Loading Test application

Usage Notes

The bootloader code runs from internal OCMC memory and occupies certain

amount of OCMC memory that is not available for application to use

during booting.

Refer to the map file for the boot loader to check for latest

information on the memory utilization in the boot loader.

Location of linker command file:

BASE_DIR\binary\bootloader\bin\<platform>\gcc

After SBL execution is complete, this region can be used as per

application requirement.

- Configuring entry point for SBL

The three files that help setup the entry point in the bootloader build

are “PDK_INSTALL_PATHpackagestistarterwaresocarmv7agccsbl_init.S”

and the linker command file

“PDK_INSTALL_PATHpackagestistarterwareexamplesgcc<device>_boot.lds”.

The global symbol Entry is used to provide the entry point to the

bootloader. The Base address of the memory section OCMCRAM (starts at 1K

offset in OCMC RAM as defined in TRM) is then used by the tiimage or

GPHEader tool to provide RBL the guidance to find the entry point to

pass control. After MLO is created check the TI image format file(

_ti.bin) to confirm that the entry point matches the location of Entry

symbol in the .map file.

NOTE

The object file created by sbl_init.S should always be the first object

file in the link order for the symbol Entry to be placed at the BASE

address of the memory section SBL_MEM

- Boot image creation tools generates a large boot image if load

sections are fragmented

Please note that when using objcopy the compiler generates a contiguous

binary that gets loaded by the bootloader at the location specified in

the header appended by TIIMAGE boot utility. IF you have some code

sections in OCMC or SRAM and some section in DDR the compiler will

generates a binary that spans across full memory range which would be in

order of MB or even GB size so it is recommended that you create compact

binaries that can be loaded into memory or implement a ELF parser to

bootloader memory sections that may be fragmented in the address space.

you can also load separate binaries for OCMC sections and DDR memory and

load the sections separately

- Removing Heap section from application binary to speed up boot

times

A common issue reported with the ARM GCC compiler is that it appends

Heap section associated with the binary to the binary image used to

boot. The Heap section is usually filled with zeros so can cause

significant delay in boot times. Essentially the bootloader will be

writing a bunch of zeros in memory so is inefficient. Following work

around has been used to circumvent the issue

Option 1: Eliminate the heap by using the compiler option

“–remove-section” as described in the E2E post below:

Refer: E2E post to configure Heap in ARM application binary by

adding

“–remove-section”

Example BIOS configuration:

var heap1 = HeapMem.create();

heap1.size = 256 * 1024 * 1024;

heap1.sectionName = ".stack";

Memory.defaultHeapInstance = heap1;

Compiler Setting : –remove-section=.stack

Option 2 Configure Segment type to be “NO LOAD” in .cfg and use

excludeSections

SYSBIOS Memory map configurations allows user to specify the section

name, length and type. by configuring the section type to “NOLOAD” and

using excludeSection option the heap memory can be eliminated from the

final binary.

Example BIOS configuration:

Program.sectMap[".biosheap"] = new Program.SectionSpec();

Program.sectMap[".biosheap"].runSegment = "DDR2"

Program.sectMap[".biosheap"].type = "NOLOAD";

Program.sectionsExclude = ".biosheap"

Alternate approach using linker command file:

.ddr3Heap (NOLOAD):

{

*(.ddr3Heap)

} > HOST_DDR3

NOTE

The approach described above helps improve boot times but Users are

recommended to initialize the HEAP sections to zeros post boot during

initialization to avoid any undesired behavior during normal operation

of the app

Debugging application boot

Steps to debug application boot using Processor SDK RTOS bootloader are

discussed in the article `Common steps to debug application

boot <https://processors.wiki.ti.com/index.php/Processor_SDK_RTOS_Boot#Common_steps_to_debug_application_boot>`__

4.5.2. AM57x

Overview

The Secondary Bootloader (SBL) for AM57xx device initializes the

execution environment for multi-core application and this can be used to

demonstrate an out-of-box experience.The section covers additional

details including execution sequence, tools and additional flashing

instructions.

Bootloader Execution Sequence

- Power On Reset

- ROM Bootloader (RBL)

- Software pre-programmed in ROM memory starts executing

- Checks Sysboot pins and choose booting device

- If no valid bootloader found on booting device, RBL checks for

next booting device.

- Platform configuration and initialization.

- Configures DPLL and clock settings for MPU, and boot media like

I2C, MMCSD, SD/MMC, SPI, QSPI, Ethernet etc for reliable boot.

- The sequence depends on RBL execution flow and Sysboot pins.

- RBL gets image size and load address by checking TI Image Header

appended on bootloader binary(.bin). Check binary formats.

- Loads the binary to internal memory at the Load address fetched

from TI Image Header

- Passes control to Secondary Bootloader(SBL)

- Secondary bootloader(SBL)

- User level secondary bootloader(SBL) begins execution from

internal memory by running basic initialization routines like

setting up Stack, BSS and then jumps to main() to begin Board

Initialization.

- Board Initialization is done by a call to Board_init() API.For

additional details refer Processor SDK Board

Support.

- It includes setting up PLLs, enabling clocks to all interfaces and

modules, performing pinmux and setting up UART console.

- Once Board Initialization is complete, it enables clocks to the

slave cores like C66x/DSP, IPU, etc and brings them out of reset.

- Parses Multicore Application image located in memory device and

copies it to DDR memory based on load address for different

sections.

- Once copy is successful it transfers control to application.

- Application then starts executing from DDR.

NOTE

- RBL requires boot loader to be in a special format with a header

appended to the binary image. The header shall contain the load

address of the bootloader and size of the bootloader image.

- For more information on the TI header refer TRM document

Directory structure

Makefiles:

- PDK_INSTALL_PATH/tibootsblboard<EVAL_BOARD>build: Makefile

for bootloader that provides list of source files and library and

compiler options to create bootloader binary.

Source Files:

- PDK_INSTALL_PATH/tibootsblboard<EVAL_BOARD>: Source to SBL

main function that consolidates all features

- PDK_INSTALL_PATH/tibootsblsoc: Source to SOC specific

initialization used in the SBL.

- PDK_INSTALL_PATH/tibootsblsrc: Source to boot media specific

initialization used in the SBL.

Tools and Binary Formats

This section lists out the various tools and scripts used by SBL for

different boot modes and those required to create a bootable application

image.

SBL/MLO image format:

To generate the

MLO, SBL uses tiImageGen tool to prepend the sbl.bin

image with the TI header information. The image format has been

described in detail in the Image Format Section of the

AM57xx

Technical Reference manual

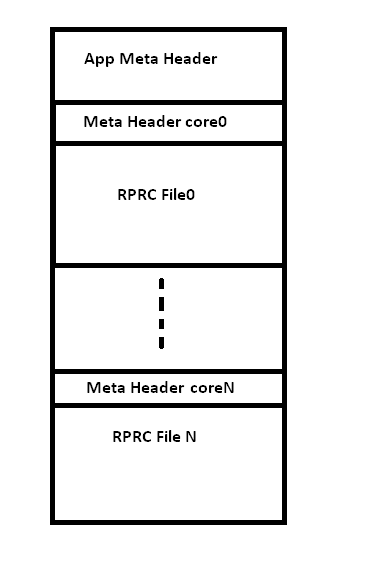

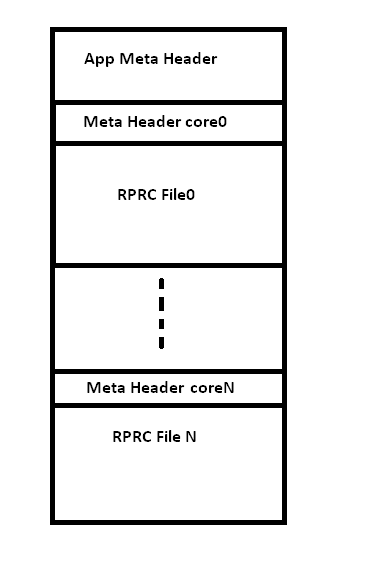

Application image format:

A bootable application image can be created by using the Am57xImageGen

script provided under tools folder as part of sbl. It can be located at

<PDK_INSTALL_DIR>packagestibootsbltoolsscripts folder.

The Am57xImageGen script uses out2rprc and multicoreImageGen format

conversion tools to create the final application image. Graphical view

of the multicore application image is provided below:

The script creates the bootable image in 2 steps

Step 1: Conversion to RPRC format conversion

- Firstly, application executable is converted from ELF/COFF format

(.out) to custom TI Rprc binary image using out2rprc tool. This tool

strips out the initialized sections from the executable file (i.e.

*.out) and places them in a compact format that the SBL can

understand. The output (bin) file is typically much smaller than the

original executable (out) file.

- The rprc files are intermediate files in a format that is consumed by

MulticoreImageGen tool that generates the final binary.

RPRC File Header Format

| Offset |

Binary value |

|---|

| 0x00000000 |

Magic Word(43525052) |

| 0x00000004 |

Entry Point (Location) |

| 0x00000008 |

Reserved Addr |

| 0x0000000C |

Section Count |

| 0x00000010 |

Version |

RPRC Section Header Format

| Offset |

Binary value |

|---|

| 0x00000000 |

Section start Address |

| 0x00000004 |

Reserved Addr |

| 0x00000008 |

Size |

| 0x0000000C |

Reserved CRC |

| 0x00000010 |

Reserved |

Step 2: Multicore Image file generation

- RPRC files for each cores is combined into a single multicore

bootable application image.

Multicore boot image format

Meta Header Start

| Offset |

Binary value |

|---|

| 0x00000000 |

Magic String (0x5254534D) |

| 0x00000004 |

Number of Files |

| 0x00000008 |

Device ID |

| 0x0000000C |

Reserved |

Meta Header per Core

| Offset |

Binary value |

|---|

| 0x00000000 |

Core ID |

| 0x00000004 |

Image Offset |

Core ID and Device ID for specific devices can be located in the file

sbl_slave_core_boot.h in the boot/sbl/soc/<SOC_NAME> folder

Refer section App Image

Creation

for more details on usage of this script and application image creation.

Flashing Tools

SBL provides a CCS based qspi flash writer utility to flash image and

multicore AppImage from a SD card to onboard QSPI device. It

is located

at <PDK_INSTALL_DIR>packagestibootsbltoolsflashWriterqspi

Building the SBL

Pre-requisites to Building

- Set your environment using pdksetupenv.bat or pdksetupenv.sh. Refer

to the Processor SDK RTOS Building page for information on setting up

your build environment

- The SBL has following dependencies and will need the following

libraries built

- Board

- UART

- I2C

- SPI

- CSL

- OSAL

- MMCSD

- PM

NOTE

Refer to the makefile for the board you are using for the latest driver

dependency. These libraries should come pre-built with any fresh

installation of the Processor SDK RTOS but may be removed if a gmake

clean is invoked

Compiling the SBL Components

To build the SBL components:

- cd <PDK>/packages/ti/board/diag

- make all BOARD=<BOARD_NAME> SOC=<SOC_NAME> BOOTMODE=<BOOTMEDIA>

- BOARD_NAME : idkAM572x, idkAM571x, evmAM572x, idkAM574x

- SOC_NAME : AM572x, AM571x, AM574x

This will make the SBL for a specific $BOARD and $BOOT_MEDIA. Output

files will be located in: <PDK>/packages/ti/boot/sbl/binary/<BOARD>

NOTE

Refer <PDK>/packages/ti/boot/sbl/sbl_<DEVICE>.sh for more build

options

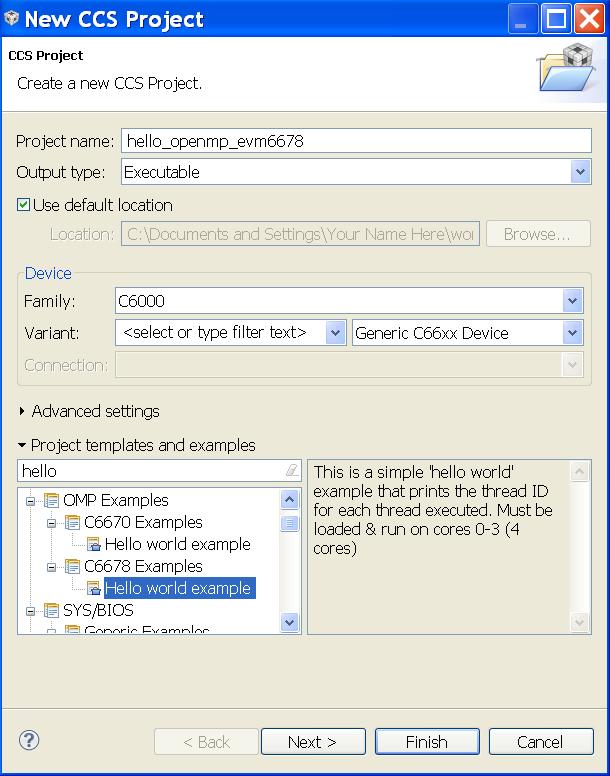

Building SBL using CCS project

The SBL build in the Processor SDK RTOS is designed to be built using

Makefile. Users can also choose to create a CCS project for the

bootloader if they prefer the IDE environment by converting the make

file based build to CCS project by linking the appropriate source files

to the project and using the same compiler options.

Example: The wiki article

“Creating_a_CCS_Project_for_SBL_on_AM572x_GP_EVM”

demonstrates creation of SBL in CCS for AM572x GP EVM.

Boot Modes

This Release of SBL supports MMCSD and QSPI Boot modes. The different

boot modes supported for all the boards is tabulated in the table below.

| |

MMCSD |

QSPI |

| AM572x GPEVM |

YES |

NO |

| AM572x IDKEVM |

YES |

YES |

| AM571x IDKEVM |

YES |

YES |

| AM574x IDKEVM |

YES |

YES |

Booting Via SD Card

- Preparing the SD card.

- Booting the target.

Preparing the SD card

- To boot the target the SD card should be bootable. Follow the steps

at Creating bootable SD card in

windows

or Creating bootable SD card in

Linux.

- Delete the “MLO” and “app” in the bootable SD card which are created

in the process of making the SD bootable.

- Copy the sbl binary(MLO) to the SD card.

- Copy the Application image(app) generated using the

Script

to the SD card.

Booting the target

- Insert micro SD card into the SD card slot of the board.

- Open a serial communication terminal like TeraTerm, MiniCom on host

PC and connect to the UART console port

- Do a power reset of the board to boot the appliation from the SD

card.

Booting Via QSPI

Booting from QSPI flash involves two steps-

- Flashing bootloader and app image to QSPI flash.

- Booting the target.

Preparing Flash Device

Use the CCS based qspi_flash_writer.out utility provided in

<TI_PDK_INSTALL_DIR>packagestibootsbltoolsflashwriterqspi<Board>’

to flash the SBL image at offset 0 and application image at offset

0x80000 to the QSPI device.

QSPI device Memory Map:

| Offset 0x00 |

SBL |

| Offset 0x80000 |

Application Multicore Image |

The images can be flashed into QSPI flash by following steps given

below.

- Copy QSPI mode SBL image

TI_PDK_INSTALL_DIRpackagestibootsblbinary<BoardName>qspibinMLO

and application image(app) generated using the Script into the SD

card.

Rename the bootloader file to ‘boot’ and application image to ‘app’

with no extensions.

- Copy ‘config’ file into the SD card, the config file should contain

names of the image to be flashed and the offset.

A sample config file can be found at

TI_PDK_INSTALL_DIRpackagestibootsbltoolsflashWriterqspiconfig.

Do not change the name of the config file.

NOTE: “config” file can be used without any modifications if

bootloader and application images are renamed to “boot” and “app”.

NOTE: Do not rename the bootloader to be copied to SD card as

“MLO”, as MMCSD bootloader expects “MLO” and “app” to boot.

- Now SD card contains 3 files 1)boot 2)app 3)config files.

config file contains the address of boot image as 0x0 and app image

as 0x80000.

Insert it into the SD card slot.

- Connect the board with CCS and and load the prebuilt qspi flash

writer application from

$(TI_PDK_INSTALL_DIR)packagestibootsbltoolsflashWriterqspibin<BoardName>\

- Run the QSPI flash writer application. You will see the following

logs on the EVM’s UART console.

- After the images have been flashed to the QSPI device disconnect from

CCS and do a power reset to boot from the QSPI memory.

PDK QSPI Flash Writer!!

Copying boot to QSPI Flash

Copying app to QSPI Flash

Changing read to quad mode

Read mode has been changed to Quad mode

SUCCESS!!!

Flashing completed

NOTE

- The file names have to be renamed in such a way that the length of

name is less than 9 characters. Any file name less than 9 characters

can be used.

- This application will flash the image at required offset without

taking into consideration any overwriting to previously flashed

image.

- It is the responsibility of the user to provide proper offsets.

Test Application

SBL provides a test application to demonstrate booting of multicore

application image on A15 and DSP cores.The multicore sample

application uses mailbox for inter-processor communication. It is used

to validate the multi-core boot-up use case.

Master application sends wake-up message to the DSP slave cores & waits

for acknowledgement message from the slave cores in an infinite

loop.Each slave DSP core waits for wake-up message from the master core

responds back with an acknowledgement message.

Application Image Creation

Application Image creation involves two steps.

- Generating the .outs of applications for individual cores

- Combining the .outs of individual cores to create a bootable

multicore image

The steps to create the bootable image in Linux and Windows environment

are listed below.

NOTE

- Valid SOC settings are AM571x/AM572x

- Valid BOARD settings are evmAM572x/idkAM571x/idkAM572x

Linux Environment:

Command to build the test application.

Go to cd (TI_PDK_INSTALL_DIR)\packages\ti\boot\sbl

make example BOARD=<BOARD> SOC=<SOC> to build the application

make example_clean BOARD=<BOARD>

Example:

make example BOARD=idkAM572x SOC=AM572x

To create the final bootable application image use the AM57xImageGen

script and follow these steps

1. Set the following environment variable in the shell. BIN_PATH:

Pointing to the path where the AppImage needs to be generated

Ex: export BIN_PATH=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary

2. Edit the script file to point to the application elf files by setting

the input application variables.

App_MPU_CPU0: Point to the path where the application .out for A15

MPU is located

App_DSP1: Point to the path where the dsp core 1 application is

located

App_DSP2: Point to the path where the dsp core 2 application is

located

export APP_MPU_CPU0=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary/idkAM572x/example/armv7/bin/sbl_app.out

export APP_DSP1=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary/idkAM572x/example/c66/dsp1/bin/sbl_app.xe66

export APP_DSP2=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary/idkAM572x/example/c66/dsp2/bin/sbl_app.xe663

export APP_IPU1_CPU0=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary/idkAM572x/example/m4/ipu1/bin/sbl_app.xem4

export APP_IPU1_CPU0=$(TI_PDK_INSTALL_DIR)/packages/ti/boot/sbl/binary/idkAM572x/example/m4/ipu2/bin/sbl_app.xem4

3. If it is not required to load an application on specific core leave

the variable blank.

- Run the script file

5. An application image by name app is created in the path pointed by

BIN_PATH variable

6. Copy the Bootlaoder image(MLO) and application(app) in the SD card to

boot using MMCSD boot mode.

NOTE

- The AM57xImageGen.sh script depends on tools like mono to execute the

out2rprc.exe.

- The linux host environment needs to have this tool installed to

execute this script.

- Refer this link to download the

mono tool

Windows environment:

Command to build the test application.

Go to cd (TI_PDK_INSTALL_DIR)\packages\ti\boot\sbl

gmake example BOARD=<BOARD> SOC=<SOC> to build the application

gmake example_clean BOARD=<BOARD>

Example:

gmake example BOARD=idkAM572x SOC=AM572x

To create the final bootable application image use the AM57xImageGen

script and follow these steps

- Set the following environment variable in windows command prompt

BIN_PATH: Pointing to the path where the AppImage needs to be generated

Ex: set BIN_PATH=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary

2. Edit the batch file to point to the application elf files by setting

the input application variables.

App_MPU_CPU0: Point to the path where the application .out for A15

MPU is located

App_DSP1: Point to the path where the dsp core 1 application is

located

App_DSP2: Point to the path where the dsp core 2 application is

located

set App_MPU_CPU0=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary\idkAM572x\example\armv7\bin\sbl_app.out

set App_DSP1=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary\idkAM572x\example\c66\dsp1\bin\sbl_app.xe66

set App_DSP2=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary\idkAM572x\example\c66\dsp2\bin\sbl_app.xe66

set App_IPU1_CPU0=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary\idkAM572x\example\m4\ipu1\bin\sbl_app.xem4

set App_IPU2_CPU0=%TI_PDK_INSTALL_DIR%\packages\ti\boot\sbl\binary\idkAM572x\example\m4\ipu2\bin\sbl_app.xem4

3. If it is not required to load an application on specific core leave

the variable blank.

- Run the batch file

5. Follow the steps 4 to 6 listed above for Linux environment.

Setup Requirements

For information on board specific requirements like power supply, UART

console port connections refer the Hardware User guide of the respective

boards.

The configurations needed to setup UART console through a serial

terminal application on host PC are listed in the next section.

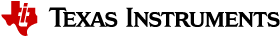

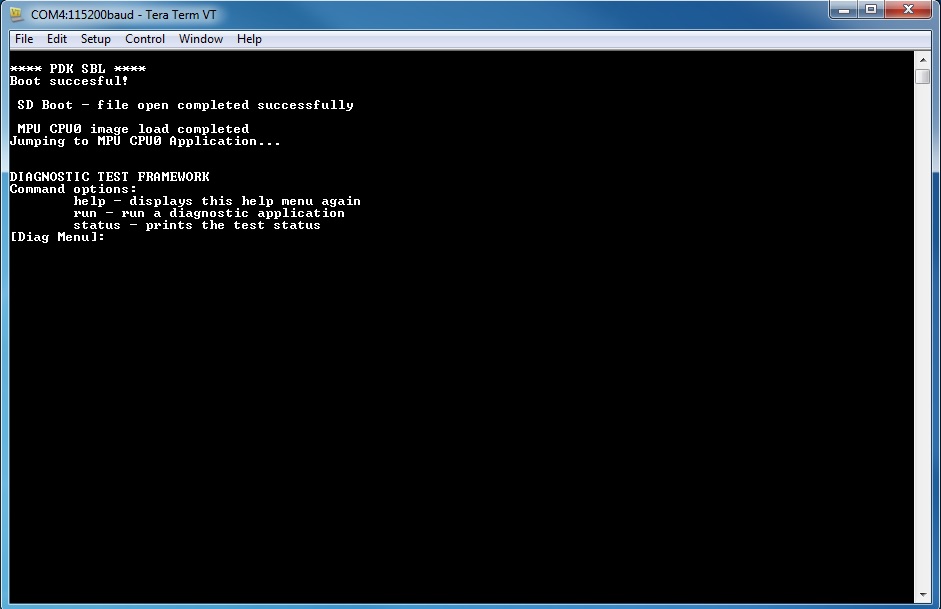

UART Console Setup

PDK SBL prints messages on the UART Serial Console running on the host.

Hence, a serial terminal application (like Tera

Term/HyperTerminal/minicom) should be running on the host.

The host serial port must be configured at 115200 baud, no parity, 1

stop bit and no flow control.

Please ensure that the local echo setting for the terminal is turned

off.

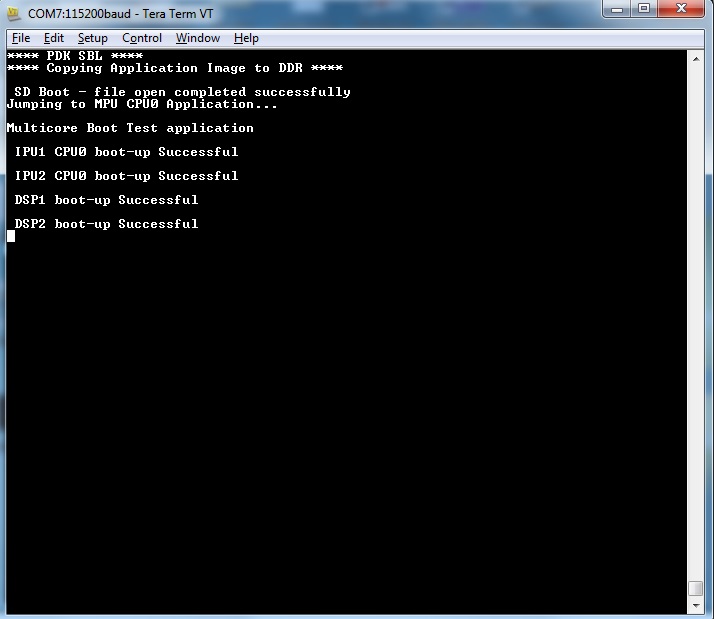

Loading the test application

Follow these steps to load the test application using a SD card on the

target

copy the MLO to your SD card (located

at %TI_PDK_INSTALL_DIR%packagestibootsblbinary[BOARD]mmcsd)

- copy the example app located at path pointed to by BIN_PATH to your

SD card

- insert your SD card into your board and power on your board

- open teraterm to connect to the board’s UART console

- press the “Hard Reset” button on your board

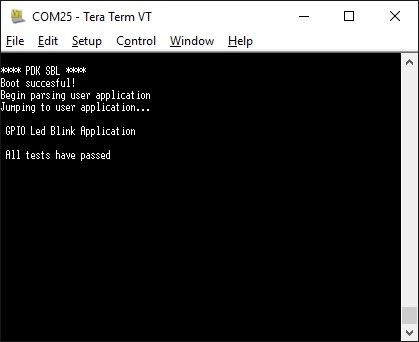

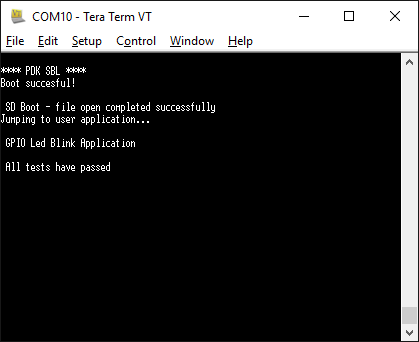

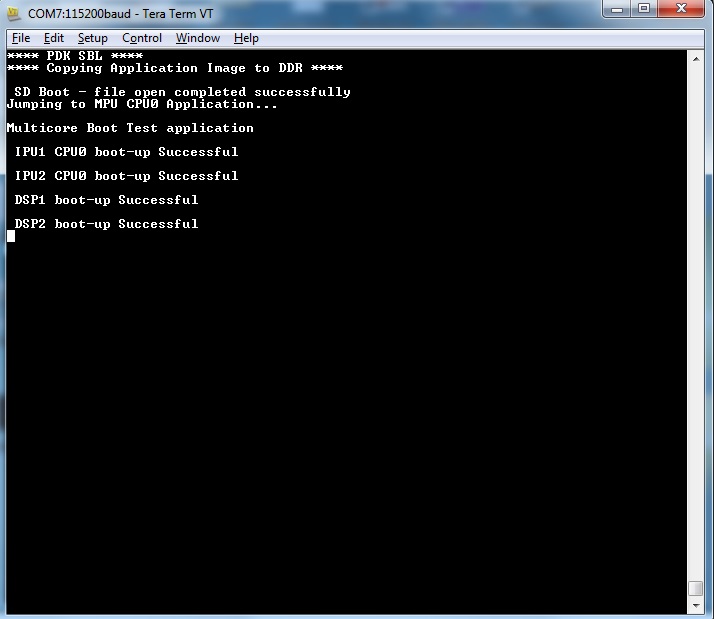

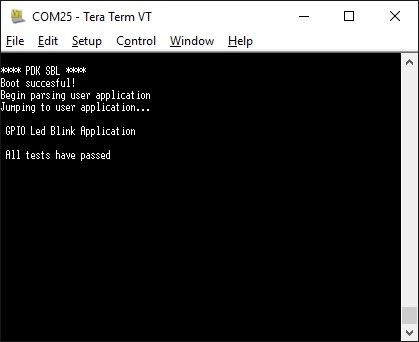

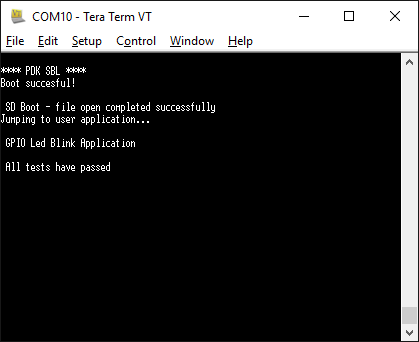

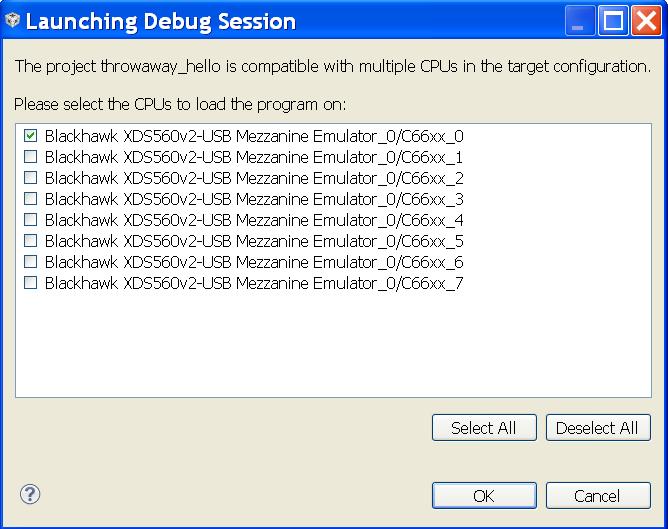

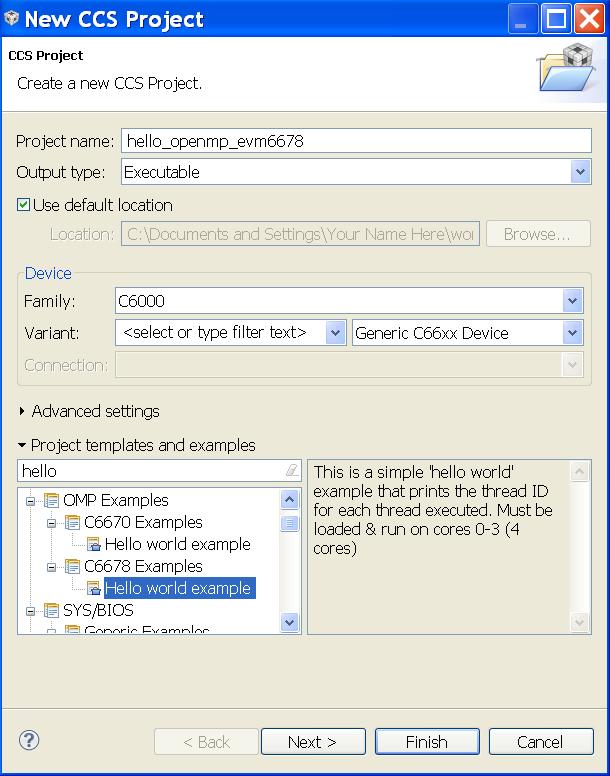

On Successful bootup you should see the following logs on the UART

console for a AM572x based board.

NOTE

MPU Core 0 example does a sequential check of mailbox messages sent from

the other cores. On rare occasions, the check happens before the message

is sent - the “<core> boot-up Successful” message might not be displayed

even though the core(s) were booted successfully.

Application Integration

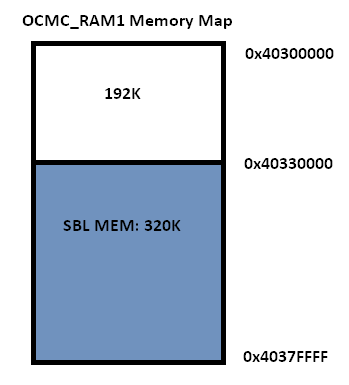

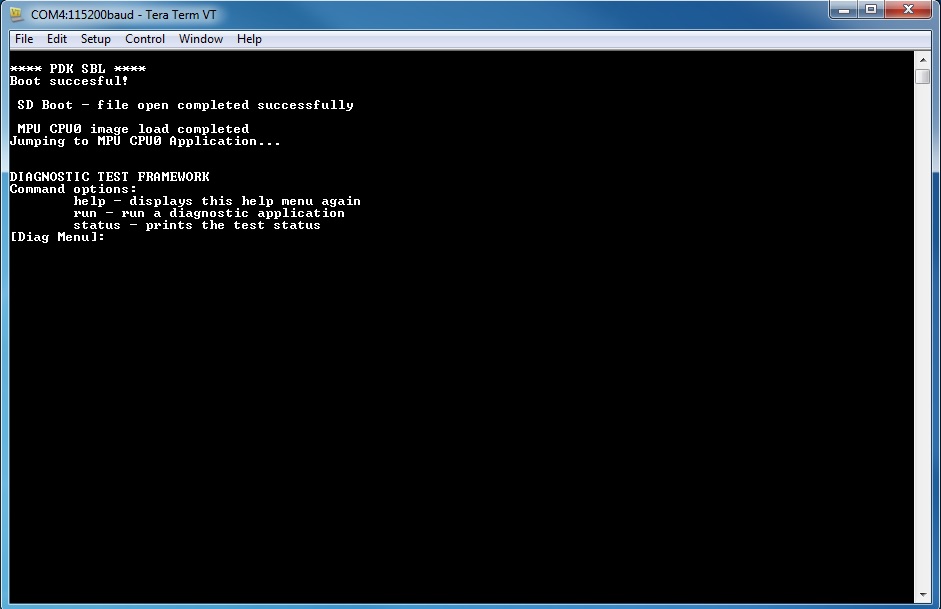

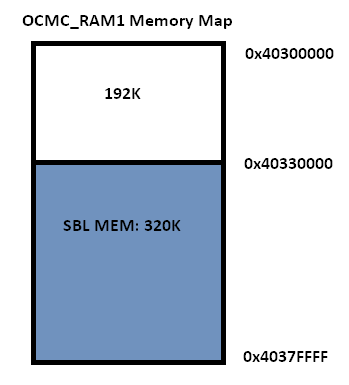

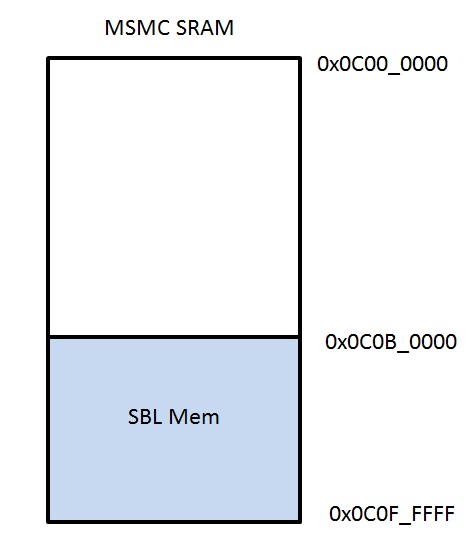

Memory Map

Table indicated below provides memory map details for SBL image in

OCMC_RAM1. For more details on pinmux and IO delay requirements refer

this link Processor SDK Board

Support

We recommend that users should refer to the linker command file and the

map file for the boot loader to check for latest information on the

memory utilization in the boot loader.

Location of linker command file:

<PDK_INSTALL_PATH>packagestibootsblboard<BOARD>build

The SBL memory map is shown below

NOTE

- After the application boots and is running on the SOC, it is free to

use the SBL_MEM region.

- The pinmux data from the board library and MMU Table are part of the

SBL_MEM region indicated in the figure above. If pinmux data needs to

be placed at a specific location then users can update the SBL linker

command file to add the BOARD_IO_DELAY_CODE and BOARD_IO_DELAY_DATA

as described in Application Integration of board library for

AM5x

SBL Customization

Changing boot media offsets

The location at which SBL resides on the flash is predefined by the ROM

bootloader spec and so these defaults can`t be changed. However the SBL

is a user defined bootloader so many of the defaults can easily be

modified to meet application requirements. For example the flash offset

location from which the bootloader reads the application is configured

in the source files located under

PDK_INSTALL_PATHpackagestibootsblsrc<BOOT_MEDIA>

Examples of customization that can be changed:

- QSPI/SPI flash offsets: These offsets are configured in sbl_qspi.c

and sbl_spi.c

- MMCSD: The name of the application is hard coded as app in function

SBL_MMCBootImage in the sbl_mmcsd.c

Speeding up boot by increasing speed of the boot interface

The SBL for AM57xx devices uses LLD drivers to read and write from boot

media supported. The SBL uses the default SOC configuration of the

drivers and the speeds setup. For example, the SPI driver default SPI

bitrate is 1 MHz (Refer

PDK_INSTALL_PATHpackagestidrvspisrcSPI_drv.c) so if you wish to

speed up boot you can update the SPI parameter in the SBL as shown

below:

SPI_Params_init(&spiParams);

spiParams.bitRate = 24000000U;

The configuration of the driver is usually done in the

boot/sbl/soc/<device>/sbl_soc.c file.

- For SD/MMC: You can configure higher speed and change bus width

using MMCSD_v1_HwAttrs_s or MMCSD_v0_HwAttrs_s

- For QSPI: 2 pin and 4 pin mode, and input frequency is configured

using QSPI_HwAttrs in the QSPI driver. Check driver for defaults.

Also, check to see if the CACHE and MMU settings for the ARM core are

setup to enable fast boot.

NOTE

SYSBOOT settings for AM57xx

The SYSBOOT configuration in your hardware using Sitara devices

(AM3/AM4/AM5) can play a big role in the time required to boot

successfully. On these devices the boot pins configure a boot sequence

for the ROM bootloader to check for valid boot image so if you have a

preferred boot mode designers are required to use SYSBOOT setup such

that the preferred boot media is first in the boot sequence. If the

preferred boot media occurs later boot sequence, the boot is likely to

add the time required by RBL to check other boot media for an valid

image. For example if QSPI is the preferred boot media on your AM57xx

hardware then you should have system configure SYSBOOT to boot of QSPI

first using SYSBOOT setting for QSPI_1 or QSPI4 for Memory preferred

booting or Production booting (Refer: Initialization chapter in

TRM).Incorrect SYSBOOT configuration can causes long delays especially

if peripheral boot is configured to be one of the preferred boot modes

in the boot order

Reducing size of SBL and application

Another way to optimize boot times is to reduce the size of the binary

that needs to be loaded by the bootloader by building the app with

optimization for code size using -Os (GNU GCC) and for -O<level> when

using TI compilers.

Other than compiler based optimizations developers can actively shutdown

non-essential modules and features to reduce code size. For example if

UART logging is not required or DDR memory is not connected in the

system, the initialization functions can be removed to reduce code size.

Usage Notes

AVS and ABB configuration is mandated for normal operation of AM57xx

devices. All Processor SDK RTOS releases v3.3 and later contain SBL that

sets up AVS and ABB configuration features using PM LLD APIs The

complete details of PMIC configuration and AVS and ABB configuration

required by the chip for different OPP has been implemented in the file:

PDK_INSTALL_PATHpackagestibootsblboardsrcsbl_avs_config.c If you

are using the same PMIC as GP EVM or IDK platform then you can reuse the

settings as is in SBL for your custom platform

- Configuring entry point for SBL

The two key files that help setup the entry point in the SBL build are

“sbl/soc/<SOC_NAME>/sbl_init.S” and the linker command file

“sbl/soc/<SOC_NAME>/linker.cmd”. The global symbol Entry is used to

provide the entry point to the SBL. The Base address of the memory

section SBL_MEM is then used by the tiimage and GP Header tool to

provide RBL the guidance to find the entry point to pass control. After

MLO is created check the TI image format file(MLO or _ti.bin) or the GP

Header file to confirm that the entry point matches the location of

Entry symbol in the sbl.map

NOTE

The object file created by sbl_init.S should always be the first object

file in the link order for the symbol Entry to be placed at the BASE

address of the memory section SBL_MEM

Debugging application boot

Steps to debug application boot using Processor SDK RTOS bootloader are

discussed in the article `Common steps to debug application

boot <https://processors.wiki.ti.com/index.php/Processor_SDK_RTOS_Boot#Common_steps_to_debug_application_boot>`__

4.5.3. C66x

Overview

C66x SOCs use the Intermediate Boot-Loader (IBL) to initialize and setup

the SOC for specific boot modes. The table below illustrates the

supported bootmodes:

| Boot Mode |

TMDSEVM6678 |

TMDXEVM6657 |

|---|

| NOR boot via IBL over I2C1 |

Yes |

Yes |

| NAND boot via IBL over I2C1 |

Yes |

Yes |

| TFTP boot via IBL over I2C1 |

Yes |

Yes |

| I2C POST boot2 |

Yes |

Yes |

| Ethernet boot |

Yes |

Yes |

| SRIO boot |

Yes |

Yes |

| PCIe boot |

Yes |

Yes |

Note:

- Support boot over I2C bus address 0x51

- Support POST boot over I2C bus address 0x50

- Only ELF and BBLOB images are supported for booting

- IBL is using the first 128KB L2 local memory, any application booting

from IBL should NOT use the first 128KB L2 memory, OR should only use

the first 128KB L2 memory for uninitialized data section

Flashing the Bootloader

IBL needs to be flashed into EEPROM address 0x51.

Refer to Processor SDK RTOS Flashing Bootable

Images] for

instructions on using the script, program_evm.js, to automatically flash

your device.

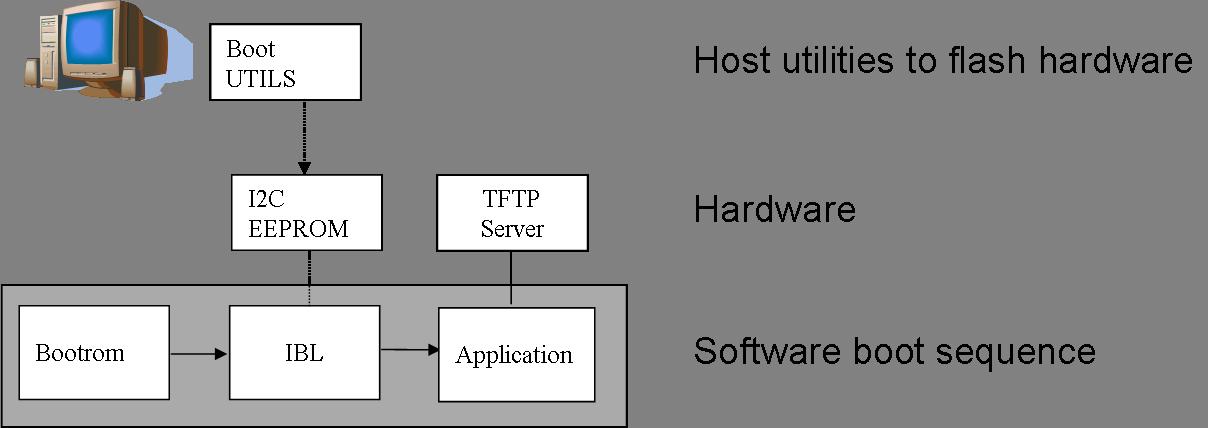

Bootloader Execution Sequence

IBL is flashed into I2C EEPROM bus address 0x51. IBL provides a

workaround for the PLL lockup issue (please refer to C6678 errata

document, February 2011, advisory 8 for details on the PLL lockup

issue). For ROM boot modes (EMAC,SRIO,PCIe,Hyperlink etc) and I2C boot

mode with bus address 0x50, DSP will initially boot from I2C EEPROM bus

address 0x51 which does the PLL reset workaround, updates the DEVSTAT

for appropriate values based on the DIP switch settings (SW3 through SW6

settings) and then re enters the ROM to accomplish the desired boot

mode. Please note that the re entry is done for all boot modes except

for PCIe boot mode and I2C boot mode with bus address 0x51.

Below are the steps done in the IBL:

- FPGA samples the bootmode pins

- FPGA forces the DSP to boot via I2C bus address 0x51

- PLL is initialized correctly by the IBL on the I2C.

- IBL reads the sampled bootmode from an FPGA register.

- IBL checks the bootmode, if it is not I2C boot or it is I2C boot but

with bus address 0x50, IBL writes bootmode into the DEVSTAT register

- IBL then checks if the bootmode is PCIE boot or not. If it is, it

executes some PCIE workaround to configure the PCIE registers (mainly

to accept spread spectrum clock) and stays inside IBL waiting for

PCIe boot.

- If it is not PCIE boot mode, IBL writes the Boot ROM entry address

into the DSP Program Counter, DSP executes the desired internal ROM

boot mode or boot from I2C bus address 0x50 as normal.

Compilation

The recommended rule-of-thumb to compiling projects in the Processor SDK

RTOS package is to use the makefiles provided. The makefiles are usable

after setting up your shell/terminal/command prompt environment with the

setupenv.bat or setupenv.sh script located in

[SDK Install Path]/processor_sdk_rtos_<platform>_<version>

Refer to Processor SDK RTOS Building the

SDK

guide on how to setup your environment for building within any of the

Processor SDK RTOS packages.

Note: C66x projects are supported by C6000 Code Generation

Tools 7.4.x. Make sure your environment variable, C6X_GEN_INSTALL_PATH,

is pointing to a valid C6000 compiler. Compiling IBL invokes the C6000

compiler, cl6x, directly. Your PATH variable will need to have

$C6X_GEN_INSTALL_PATH/bin.

The IBL package can be found in:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/ibl

To build:

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/make

make <IBL_BINARY_NAME> ENDIAN=<BINARY_ENDIANNESS> I2C_BUS_ADDR=0x51

<IBL_BINARY_NAME> can be of values: evm_c6657_i2c or

evm_c6678_i2c. (For C6657 or C6678 platforms, respectively)

<BINARY_ENDIANNESS> can be of values: little or big

I2C_BUS_ADDR specifies the I2C bus address to use, and has to be 0x51

for C66x SOCs to access the EEPROM.

The resulting output will be in [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/make/bin

directory.

NOTE

For developers, who want to build IBL in Windows environment. Please

build this using MinGW environment using the instructions provided in

the build_instructions.txt that can be found under

pdk_c66xx_xx_xxpackagestibootibldocibldoc

Flash Writers

There are three types of flash memory provided with the C66x SOCs:

EEPROM, NOR, and NAND. Each of these flash memory can hold bootable

application binaries. As such, respective flash writers are provided in:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/writer

Note: Please set your EVM to NO BOOT mode before loading

and running any of the flash writers. Flashing in NO BOOT mode is the

safest way since it eliminates any unwarranted interactions with booted

applications.

EEPROM Writer

The EEPROM Writer is used to write a binary into the EEPROM memory.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/writer/eeprom/<platform>/build

make all

Usage

- Set your EVM to NO BOOT. Power on, launch target configuration in

CCS, and connect to Core 0. Be sure the GEL file is used and DDR is

initialized.

- Copy the desired binary you want to flash to [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/eeprom/<platform>/bin

directory.

- Rename the binary you copied in the previous step to “app.bin”.

- In CCS, select Core 0 and open the Memory Browser

- In the Memory Browser window, right click and select “Load Memory”

- Load your app.bin to 0x0C000000. Do so by selecting app.bin for the

file, click Next, and input 0x0C000000 for Start Address (Type-size

selected should be 32-bit)

- Load [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/eeprom/<SOC>/bin/eepromwriter_<platform>.out

- Run Core 0. This will program the flash memory.

If it succeeds, the console will print “EEPROM programming completed

successfully”

NOR Writer

The NOR Writer is used to write a binary into the NOR memory.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nor/<platform>/build

make all

Usage

- Set your EVM to NO BOOT. Power on, launch target configuration in

CCS, and connect to Core 0. Be sure the GEL file is used and DDR is

initialized.

- Copy the desired binary you want to flash to [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nor/<platform>/bin

directory.

- Rename the binary you copied in the previous step to “app.bin”.

- In CCS, select Core 0 and open the Memory Browser

- In the Memory Browser window, right click and select “Load Memory”

- Load your app.bin to 0x80000000. Do so by selecting app.bin for the

file, click Next, and input 0x80000000 for Start Address (Type-size

selected should be 32-bit)

- Load [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nor/<SOC>/bin/norwriter_<platform>.out

- Run Core 0. This will program the flash memory.

If it succeeds, the console will print “NOR programming completed

successfully”

NAND Writer

The NAND Writer is used to write a binary into the NAND memory.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nand/<platform>/build

make all

Usage

- Set your EVM to NO BOOT. Power on, launch target configuration in

CCS, and connect to Core 0. Be sure the GEL file is used and DDR is

initialized.

- Copy the desired binary you want to flash to [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nand/<platform>/bin

directory.

- Rename the binary you copied in the previous step to “app.bin”.

- In CCS, select Core 0 and open the Memory Browser

- In the Memory Browser window, right click and select “Load Memory”

- Load your app.bin to 0x80000000. Do so by selecting app.bin for the

file, click Next, and input 0x80000000 for Start Address (Type-size

selected should be 32-bit)

- Load [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/writer/nand/<SOC>/bin/nandwriter_<platform>.out

- Run Core 0. This will program the flash memory.

If it succeeds, the console will print “NAND programming completed

successfully”

Boot Modes

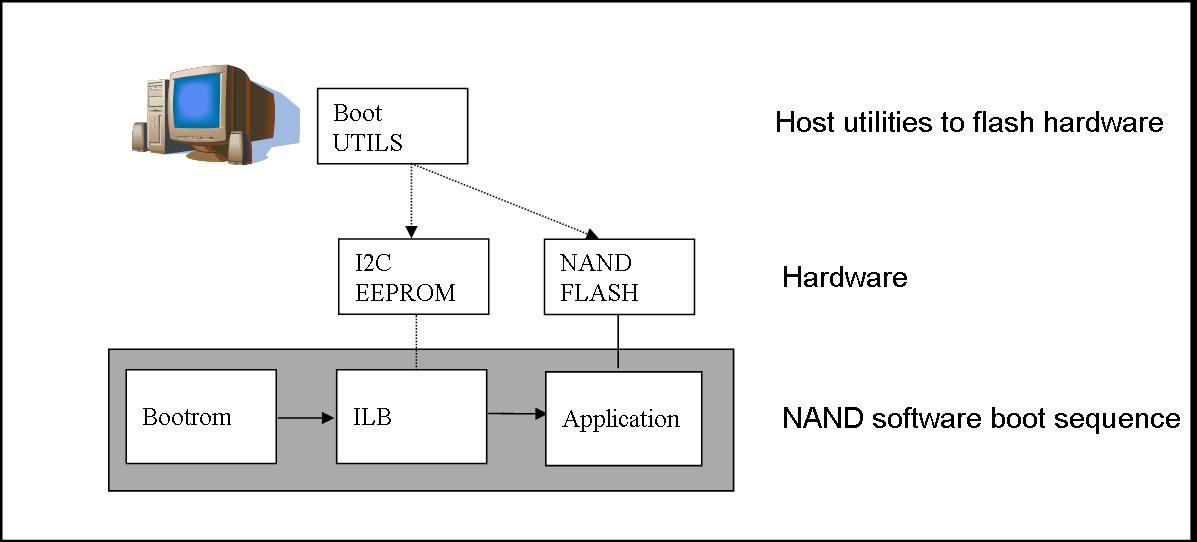

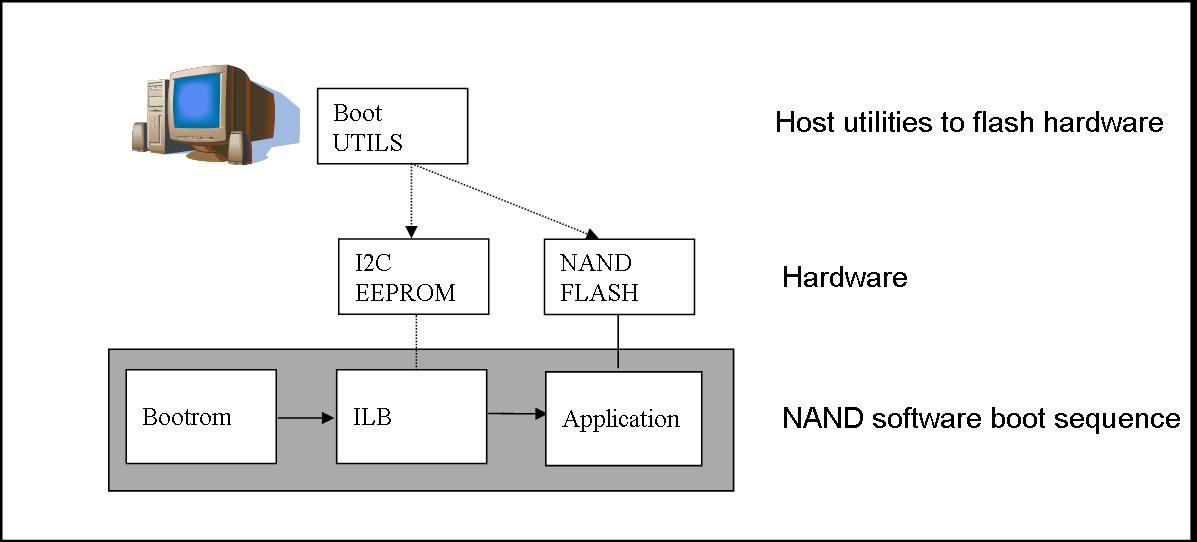

NAND Boot

NAND boot is a multi-stage process which is designed to boot an

application from NAND flash after reset. Figure below illustrates the

elements of the NAND boot process.

On reset the DSP starts execution with the bootrom which transfers

execution to the secondary bootloader from EEPROM using the I2C slave

bus address 0x51. The secondary bootloader loads the application program

from NAND flash then transfers control to the application. To execute

the NAND bootloader you must ensure the DIP switches for your platform

are properly configured for I2C Master Boot and address 0x51, AND

the boot parameter index dip switch should be set to 2 or 3.

NAND boot supports multiple images booting. Depending on the boot

parameter index dip switch, maximum 2 boot images can be supported. By

default NAND boot only supports a BBLOB image format, if the customer

wants to boot an ELF image, the IBL configuration table needs to be

modified and re-programmed to EEPROM.

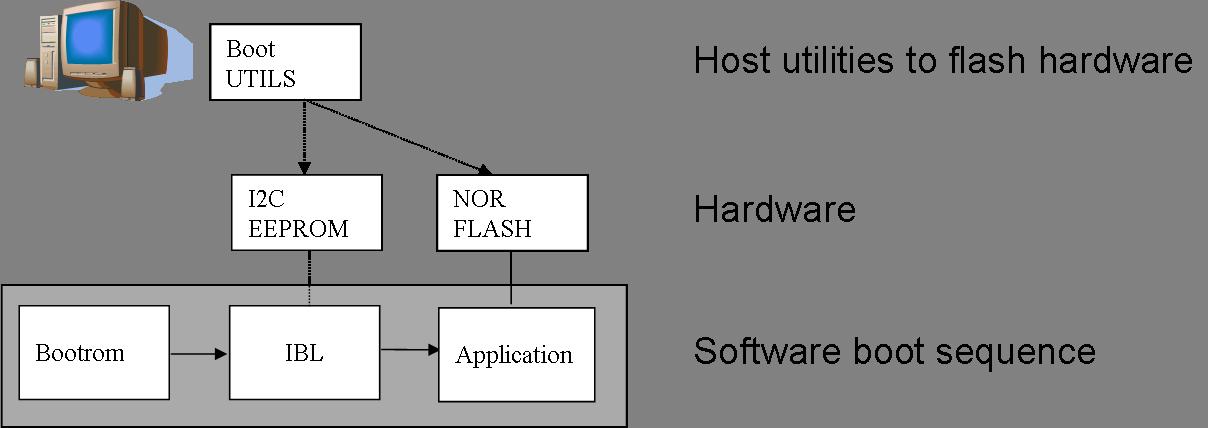

NOR Boot

NOR boot is a multi-stage process which is designed to boot an

application from NOR flash after reset. Figure below illustrates the

elements of the NOR boot process.

On reset the DSP starts execution with the bootrom which transfers

execution to the secondary bootloader from EEPROM using the I2C slave

address 0x51. The secondary bootloader loads the application program

from NOR flash then transfers control to the application. To execute the

NOR bootloader you must ensure the DIP switches for your platform are

properly configured for I2C Master Boot and address 0x51, AND the boot

parameter index switch should be set to 0 or 1.

NOR boot supports multiple images booting. Depending on the boot

parameter index dip switch, maximum 2 boot images can be supported.

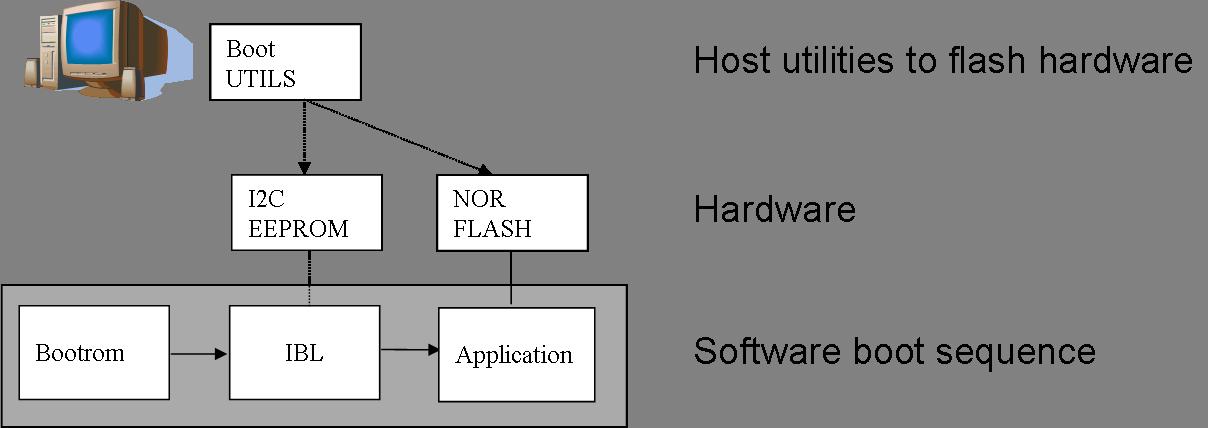

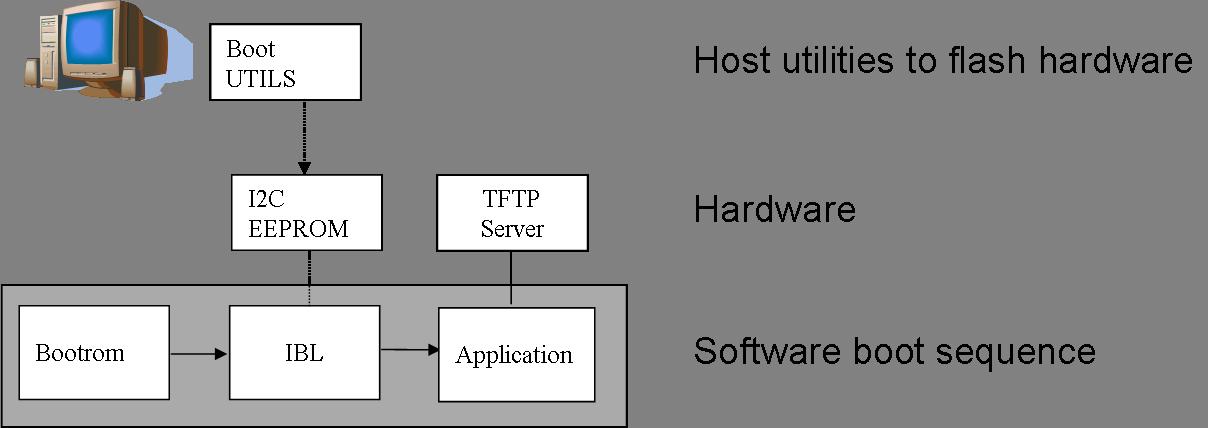

TFTP Boot

EMAC boot is a multi-stage process which is designed to boot an

application from TFTP server after reset. Figure below illustrates the

elements of the EMAC boot process.

On reset the DSP starts execution with the bootrom which transfers

execution to the secondary bootloader from EEPROM using the I2C slave

address 0x51. The secondary bootloader loads the application program

from a remote TFTP server then transfers control to the application. To

execute the EMAC bootloader you must ensure the DIP switches for your

platform are properly configured for I2C Master Boot and address 0x51,

AND the boot parameter index switch should be set to 4. By default EMAC

boot only supports a BBLOB image format, if the customer wants to boot

an ELF image, the IBL configuration table needs to be modified and

re-programmed to EEPROM.

Updating the IBL Ethernet Configurations

There are two ways to update the IBL ethernet configurations for

ethernet boot.

Using CCS

- Turn on and connect to your EVM with the appropriate Target

Configuration file.

- Connect to Core 0.

- Go to Run -> Load Program and select i2cparam_0x51_c667#_le_0x500.out

located in [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/make/bin

- Go to Tools -> GEL Files and then right click on GEL Files window and

Load the i2cConfig.gel GEL file, located in [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/make/bin

- Run the program. The following message will be printed on the CCS

console: Run the GEL for the SOC to be configured, press return to

program the I2C. DO NOT PRESS ENTER UNTIL STEP 6 IS DONE

- Run the GEL script”Scripts -> EVM c6678 IBL” -> setConfig_c6678_main.

- Now press “Enter” in the CCS console window, and the program will

write the boot parameter table to the EEPROM. On success the message

“I2c table write complete” will be printed on the CCS console.

Please note that the i2cConfig.gel file can be modified via a text

editor before loading and running the script in CCS. Please note that

this gel file contains configuration settings for multiple SOCs and

multiple boot modes.

Using iblConfig Utility Program

The second way to update the IBL ethernet configurations is to use

iblConfig.out. This utility program is located under:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/util/iblConfig/build

In command line, use “make” with the given Makefile to generate

iblConfig.out and input.txt. Please be sure to fill in the parameters

for input.txt before running iblConfig.out; below is an example of

input.txt:

file_name = ibl.bin

SOC = 6

offset = 0x500

ethBoot-doBootp = TRUE

ethBoot-bootFormat = ibl_BOOT_FORMAT_ELF

ethBoot-ipAddr = 192.168.1.3

ethBoot-serverIp = 192.168.1.2

ethBoot-gatewayIp = 192.168.1.1

ethBoot-netmask = 255.255.255.0

ethBoot-fileName =

The first 3 parameters must be filled in for iblConfig.out to work:

- file_name refers to the IBL binary file to update. This file must be

in the same directory as iblConfig.out.

- SOC refers to the SOC being used. Please enter 6 for C6678, and 8

for C6657.

- offset refers to an offset space in the IBL. The value is 0x500 for

C6678, and C6657

The ethernet parameters (the entries beginning with ethBoot) refer to

specific ethernet configurations. If they are not specified, they will

be defaulted to the values in the [SDK Install

Path]/pdk_<platform>_<version>/packages/ti/boot/ibl/src/util/iblConfig/src/SOC.h

file. In the example above, the ethernet boot file name will be

defaulted to c6678-le.bin when iblConfig.out is run.

After running iblConfig.out and updating the IBL binary, you must

flash the modified IBL binary to your EVM. You can do this as part of

program_evm (refer to

Processor SDK Flashing Bootable

Images) or

you can flash it individually using eepromwriter (refer to “Flash

Writers” section above).

- Note: If you updated the IBL with iblConfig and flashed it

- with eepromwriter, you should NOT use

i2cparam_0x51_c667#_le_0x500.out and iblConfig.gel - this would

overwrite the changes you made to the IBL.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/i2c/tftp/<platform>/build

make all

Usage

After your IBL ethernet settings are configured correctly and flashed

into EEPROM memory, follow these steps to continue the TFTP booting

process:

- Start a TFTP server on your local PC. Your local PC will be the one

sending the image to be booted, so make sure your PC and EVM are

connected to the same subnet via ethernet

- Copy i2ctftpboot_<platform>.out (refer to compilation step above) to

your base TFTP directory

- Rename i2ctftpboot_<platform>.out to app.out

- Set the IP address of the PC that is running the TFTP server to

192.168.2.101, since by default IBL will set the EVM IP address to

192.168.2.100 and the TFTP server IP address to 192.168.2.101

- Set EVM to TFTP boot mode and power on the EVM

Your PC will send the application image to the EVM to boot. Open an UART

terminal to view the output.

POST Boot

POST (Power On Self Test) Boot is designed to do a quick self-diagnostic

upon boot. The POST application itself is located in

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/post

This application should already be compiled and flashed into EEPROM

out-of-box. Below instructions are for re-compilation or re-flashing

only.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/post/<platform>/build

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/post/<platform>/bin

./post_romparse.sh

Note: You would need to use post_romparse.bat instead of the *.sh

version if your host system is running on Windows.

Usage

To flash the POST binary into EEPROM:

- Refer to above Flash Writers section on flashing EEPROM memory. The

binary you are flashing is “post_i2crom.bin”.

- Before running the last step of the EEPROM flashing instruction to

run the DSP core, modify the eepromwriter_input.txt to use

0x50 for the bus_addr field. The eepromwriter_input.txt file

is located in:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/writers/eeprom/<SOC>/bin

Configure your EVM’s DIP Switches accordingly to I2C POST BOOT mode. The

POST application will be loaded from EEPROM 0x50 and output will be

available over the UART serial console.

ETHERNET Boot

ETHERNET Boot uses Ethernet sockets to transfer a bootable image from a

host to the EVM. After powering on in Ethernet boot mode, the EVM will

send BOOTP packets at regular interval - this gives visibility of the

MAC ID of the EVM to the network.

Below are instructions on compiling and running an example to send a

simple program to the EVM while in Ethernet boot mode.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/ethernet/Utilities

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/ethernet/simple

make all

Usage

- Set the EVM’s DIP switches to Ethernet boot mode. Connect Ethernet

cables such that the EVM and your Host PC are on the same network.

- Power on the EVM. The EVM will start sending BOOTP packets. Read the

packets for the EVM’s MAC ID. You can read the packet by using a

network tool such as Wireshark.

- On your Host PC, add an ARP entry to associate the EVM’s MAC ID with

an IP address on your network.

- Use the pcsendpkt utility provided to send the simple.eth program

compiled in the compilation step to the EVM.

To use pcsendpkt:

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/ethernet/Utilities

pcsendpkt simple.eth <EVM IP ADDRESS>

<EVM IP ADDRESS> is the IP address you assigned the EVM in step 3

Note: If you are on a Linux Host PC, you may need to

recompile pcsendpkt locally with GCC

To verify, connect to the EVM’s Core 0 via CCS and check that the A1

register is set to 0x11223344

SRIO Boot

SRIO boot will attempt to load and run a binary image received via SRIO.

An example can be found in:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio

Below are instructions on compiling and running the SRIO boot example.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio/srioboot_ddrinit/<platform>/build

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio/srioboot_ddrinit/<platform>/bin

./srioboot_ddrinit_elf2HBin.sh

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio/srioboot_helloworld/<platform>/build

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio/srioboot_helloworld/<platform>/bin

./helloworld_elf2HBin.sh

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/srio/srioboot_example/<platform>/build

make all

Note: You would need to use srioboot_ddrinit_elf2HBin.bat and

helloworld_elf2HBin.bat instead of their *.sh version respectively if

your host system is running on Windows. Compilation of the projects

should be done in the order stated above.

Usage

You will need to have 2 EVMs - both should be set to SRIO boot mode. The

two EVMs will be connected through the AMC breakout board (lane x of one

slot should be connected to lane x of the other breakout slot). One EVM

will be acting as the host (referred to as the HOST EVM) and the other

EVM will be doing the booting (referred to as the BOOTING EVM).

- Compile srioboot_example_evm66XXl.out

- Connect the BOOTING EVM’s UART serial port to your PC using the

RS-232 cable

- Connect a JTAG emulator on the HOST EVM

- Power on both EVMs

- Open an UART terminal to view the BOOTING EVM’s output. (Remember to

set the baud rate to 115.2k bps, 8-bit data, no parity, 1-bit stop,

and no flow control)

- Connect to the HOST EVM via Code Composer Studio (CCS is recommended

to be version 6 or higher). Launch target configuration for your HOST

EVM and connect to DSP0.

- Load and run srioboot_example_evm66xxl.out on your HOST EVM

CCS console for your HOST EVM should display:

[C66xx_0] SRIO Boot Host Example Version 01.00.00.01

[C66xx_0]

[C66xx_0] Transfer DDR init code via SRIO successfully

[C66xx_0] Transfer boot code via SRIO successfully

Terminal for your BOOTING EVM should display:

SRIO Boot Hello World Example Version 01.00.00.01

Booting Hello World image on Core 0 from SRIO ...

Booting Hello World image on Core 1 from Core 0 ...

Booting Hello World image on Core 2 from Core 0 ...

Booting Hello World image on Core 3 from Core 0 ...

Booting Hello World image on Core 4 from Core 0 ...

Booting Hello World image on Core 5 from Core 0 ...

Booting Hello World image on Core 6 from Core 0 ...

Booting Hello World image on Core 7 from Core 0 ...

PCIE Boot

PCIE boot will attempt to load and run a binary image upon enumeration.

Example is located:

[SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/pcie

Below are instructions on compiling and running the PCIE boot example.

Compilation

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/pcie/pcieboot_ddrinit/<platform>/build

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/pcie/pcieboot_helloworld/<platform>/build

make all

Additionally for C6678 EVM:

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/pcie/pcieboot_interrupt/<platform>/build

make all

cd [SDK Install Path]/pdk_<platform>_<version>/packages/ti/boot/examples/pcie/pcieboot_localreset/<platform>/build

make all

The POST application can also be used as a PCIE Boot example. Run the

corresponding *_elf2HBin.bat (or .sh) to convert the .out files into

PCIE bootable binaries.

Usage

An AMC to PCIE adaptor card, a TMS320C66xxL EVM card and a Linux PC are

required to do the test. The test is verified on both TMS320C6670L and

TMS320C6678L cards, with both 32-bit and 64-Linux PCs running Ubuntu

10.04. Other Linux OS are expected to work as well.

- Before connect the system, please update IBL with the latest from

Processor SDK

- Set EVM card to PCIE boot (refer to hardware page)

- Assemble the EVM card into the adaptor card

- Connect the URAT cable from EVM card to a Linux PC’s USB port or

serial port

- Completely shut off the PC power supply (by disconnecting the power

cord), insert the AMC adaptor card (with EVM mounted) into an open

PCIE slot in PC’s motherboard

- Supply the power to PC, wait for a few seconds and power on the PC.

- Make sure the PCIE device is correctly enumerated by PC by checking

below, note DEVICE_ID field is changed from 0x8888 to 0xb005 which is

programmed in IBL.

- Either enter PC’s BIOS setting when PC is booting up, a new PCIE

device should be populated in the PCIE slot where card is inserted,

shown as a “Multimedia device”.

- Or, type “lspci –n” under Linux command shell after Linux OS is

loaded, a TI device (VENDOR_ID: 0x104c) should be in the list:

local-ubuntu:~$ lspci -n

00:00.0 0600: 8086:2774

00:1b.0 0403: 8086:27d8 (rev 01)

….

00:1f.3 0c05: 8086:27da (rev 01)